Shanghai Gengyun Industrial Co., Ltd

What is ADSS Fiber Optic Cable?

What is adss cable ? ADSS, an acronym for All Dielectric Self-Supporting cable, refers to a type of fiber optic cable that eliminates the necessity for metallic support wires due to its self-supporting design. The term “dielectric” signifies its insulating nature.

Given that ADSS fiber cable operates without requiring any additional running wires for support. It has gained extensive application in outdoor settings. Electric utilities have adopted it as a communication channel, seamlessly integrated alongside pre-existing overhead power transmission lines.

What Is ADSS Cable?

ADSS cable is a type of fiber optic cable that is strong enough to support itself between structures without containing conductive metal elements. Both single mode and multimode fibers can be arranged in ADSS cables with a maximum of 144 fibers. ADSS fiber optic cable is designed for outside plant aerial and duct applications in local and campus network loop architectures from pole-to-building to town-to-town installations. The cabling system that includes cables, suspension, dead-end, and termination enclosures offers a comprehensive transmission circuit infrastructure with high-reliability performance.

Types of ADSS fiber cable

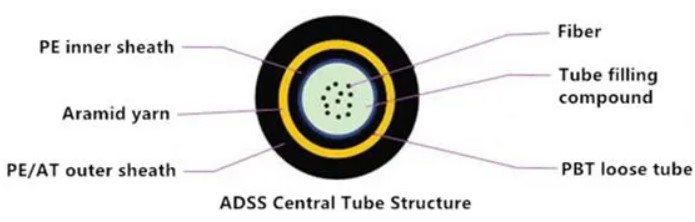

Central Tube Structure

In the central tube construction, the optical fibers are arranged within a Polybutylene Terephthalate (PBT) loose tube. It is filled with a water-blocking compound over a specified length. PBT, a thermoplastic engineering polymer, serves as an effective insulator in electrical and electronic applications.

Subsequently, these fibers are enveloped with aramid yarn, a heat-resistant and highly durable synthetic fiber, tailored to meet the desired tensile strength requirements. The entire assembly is then encased in either a Polyethylene (PE) sheath (suitable for electric field strengths up to 110KV) or an AT sheath (suitable for electric field strengths of 100KV and above). PE, a widely utilized thermoplastic polymer, is renowned for its use in manufacturing parts and components. This design boasts a compact diameter and lightweight construction, albeit with limitations in terms of achievable lengths.

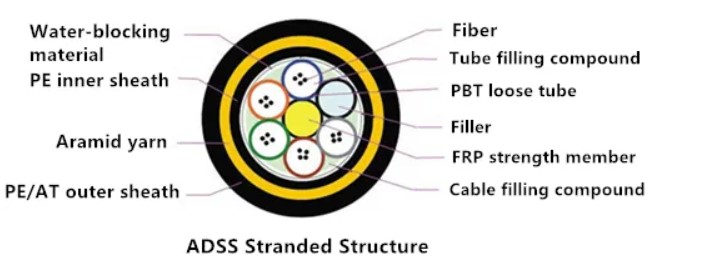

Stranded Structure

The fiber loose tubes are surrounding around a central strength member (usually as FRP material). Fiber-reinforced polymer (FRP), also Fiber-reinforced plastic, is a composite material made of a polymer matrix reinforced with fibers. The fibers are usually glass, carbon, or aramid, although other fibers such as paper or wood or asbestos have been sometimes used.

And the rest parts are similar to the central tube structure. This type is able to obtain a longer fiber length. Although the diameter and weight are relatively big, it is better to be deployed for large span applications.

Conclusion

ADSS cables are ideally suited for installations across both distribution and transmission settings. Offering a versatile solution that accommodates a wide range of fiber counts and span lengths, they have become increasingly favored by aerial cabling system designers in various telecommunications sectors. Including power utilities, telecommunications companies, and private network providers. By marrying convenience with cost-efficiency, aerial fiber-optic deployments rely on these adss fiber optic cables to enhance overall performance.

If you have any fiber optic cable needs, ofec and toem engineers can provide you with the right cable solutions.