Shanghai Gengyun Industrial Co., Ltd

Common Types of Optical Fiber Coating: UV Curable Fiber Optic Coating

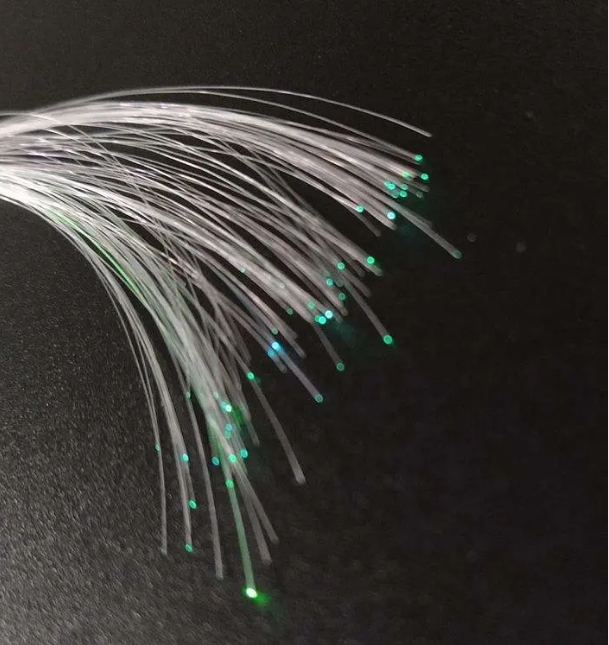

Coatings play a key role in helping optical fibers meet environmental and mechanical specifications as well as some optical performance requirements. When optical fiber are stretched without coating, the outer surface of the glass cladding will be exposed to air, moisture, collisions, abrasion, small bends and other hazards. These phenomena will cause defects on the surface of the glass. Initially, these defects may be small or even microscopic. But over time, the applied stress and contact with water will turn into larger cracks and eventually lead to failure. The role of the coating is to protect the glass surface. Therefore, all optical fibers have a protective coating when stretched.

What is Optical Fiber Coating ?

The optical fiber coating material is usually a polymer that is applied in a very thin layer to the outside of the optical fiber. It is mainly used to coat the outside of the optical fiber to protect the optical fiber. The role of optical fiber coating is mainly reflected in three aspects. First, optical fiber coating can effectively protect the optical fiber from moisture, dust, chemicals and mechanical stress. Thereby extending the service life of the optical fiber. Secondly, the fiber coating can increase the mechanical strength of the optical fiber, making it more resistant to external forces such as bending and stretching. This can reduce the risk of optical fiber breakage during use. Finally, the coating can also reduce the signal attenuation of the optical fiber during transmission and improve the transmission efficiency and quality of the optical fiber.

Most Common Optical Fiber Coating Resin: UV Curable Fiber Optic Coating

UV Curable Fiber Optic Coating means that the coating material is cured using UV light. UV curing makes the process fast and efficient due to the high UV peak irradiance, thus achieving maximum fiber production speed. UV curable coating also prevent corrosion from cable gel. Cable gel can prevent bending and breaking and is waterproof. But it can also degrade the cable over time. UV-cured coatings help prevent this decay.

What are the advantages of UV Curable Coating ?

The biggest advantage of UV curable coating is that it can save the cost of producing optical fiber.Using UV to accelerate the curing of coating has other advantages. Such as:

- Faster curing time;

- Improved marking quality and accuracy;

- Reduced energy consumption;

- UV curable coating Reduced maintenance costs;

- Increased productivity;

- UV-cured fiber optic coating Reduced carbon emissions;

- UV-cured markers are extremely durable and will not fade or peel off over time;

- Lower heat emission results in lower fiber surface temperature;

- Optimized cooling design maximizes the life of all lamp components;

- UV equipment is easily retrofitted (or upgraded) to conventional microwave power supply;

- Easy replacement of lamps and reflectors reduces fiber production line downtime;

- UV intensity on the fiber is 35% higher and light output is more stable;

Application of UV Curable Fiber Optic Coating

UV coating of optical fiber is suitable for fiber drawing towers or specialty fiber machines and fiber ribbon cables.

Conclusion

Optical Fiber Coating material protect optical fibers from environmental factors. Such as moisture, heat, and abrasion, while also improving the optical properties of optical fibers. In the future, more and more high-value coating materials will appear, but UV curable coating are still the best solution for optical fiber coating materials.