Shanghai Gengyun Industrial Co., Ltd

What is Central Tube Optical Fiber Cable?

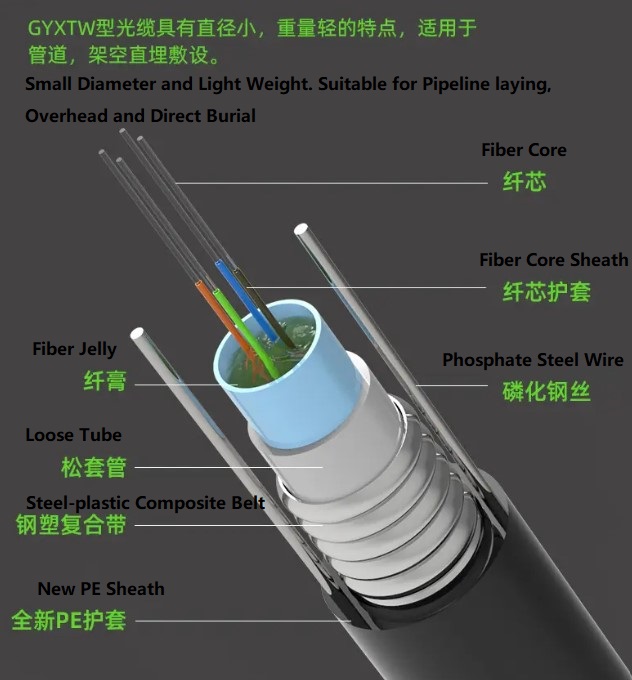

What is central tube optical fiber cable? The structure of optical cable is that 250lJm optical fiber is put into a loose tube made of high modulus material. The loose tube filled with waterproofing compound. The loose tube longitudinally wrapped with a layer of double-sided plastic-coated tape (PSP), and water-blocking material added between the steel tape and the loose tube to ensure precise installation and axial water blocking. Two parallel steel wires placed on both sides and then a polyethylene sheath made into a cable.

Features of Central Tube Optical Fiber Cable

- Small outer diameter, light weight, easy construction;

- The excess length of optical fiber controlled stably;

- The additional attenuation of the optical fiber is close to zero. The dispersion value does not change;

- Excellent environmental performance;

5_Excellent water-blocking layer, with good water-resistance;

- Steel emperor bonding outer sheath and metal reinforcement, excellent tension performance;

- The central design of the bundle tube reduces the lateral force of the cable when it is untied;

Fiber Core of Central Tube Optical Fiber Cable

For central tube fiber optic cable, the maximum number is usually 12 cores. If it greater than 24 cores, black dots printed on the cores of the same color. To distinguish. However, most of our cases are 4, 6, 8, and 12 cores.

Single Mode and Multimode Central Tube Optical Fiber Cable

Central tube optical fiber cables aralso divided into single-mode and multi-mode.

G.652 Fiber Optic

G.652: Conventional single-mode fiber (dispersion-non-shifted single-mode fiber), with the shortest cutoff wavelength. It can used for both 1550nm and 1310nm. Its characteristics are that the dispersion is zero when the wavelength is around 1310nm during design and manufacturing. The loss is the smallest at the wavelength of 1550nm, but the dispersion is the largest. The attenuation of the 1310nm window is 0.3~0.4dB/km. The dispersion coefficient is 0~3.5ps/nm.km. The attenuation of the 1550nm window is 0.19~0.25dB/km. The dispersion coefficient is 15-18ps/nm.km. The main disadvantage is that the dispersion coefficient is large in the 1550 band. It is not suitable for long-distance applications above 2.5Gb/s.

G.652A and G.652B Fiber Optic

G.652A and G.652B is a basic single-mode fiber, and G.652C⁄D is a low water peak single-mode fiber. Compare IEC standard B1.1, B1.2, and B1.3 respectively. G.655: Non zero-Dispersion-Shifted Fiber (NZ-DSF: Non zero-Dispersion-Shifted Fiber). G.653 fiber has zero dispersion at 1550nm wavelength. G.655 fiber has concentrated or positive or negative dispersion. This reduces the adverse effects of nonlinear phenomena that interfere with adjacent wavelengths in DWDM systems.

Application of Central Tube Fiber Optic Cable

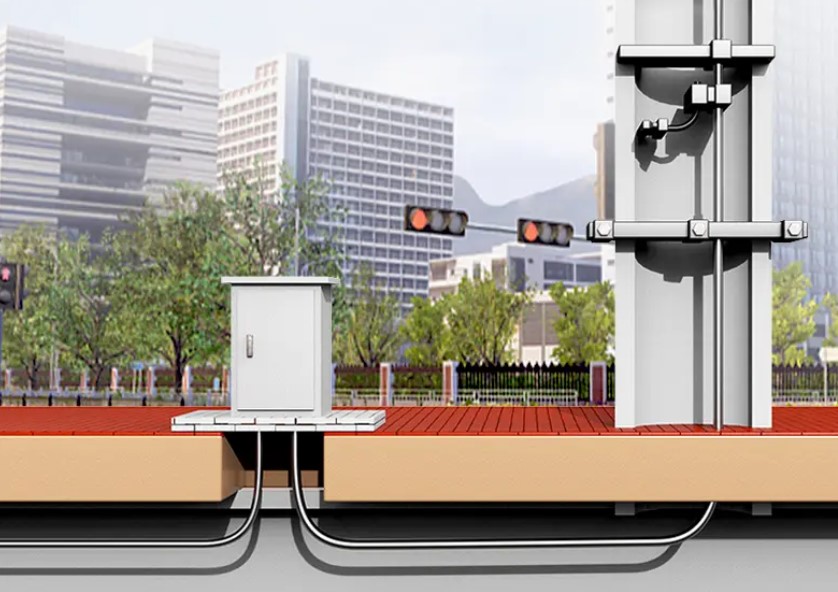

Central tube bundle optical cables often used in pipeline laying, channel direct burial, overhead installation, computer room control and other scenarios.

Structure of Central Tube Optical Fiber Cable

1.Bundle Tube

The material of the bundle tube is PBT. This material is hard and flexible, and resistant to lateral pressure. Some small factories use PP instead of PBT, which can reduce the cost by half. However, the optical fiber inside the optical cable is easy to break during transportation and construction. The color of PP is translucent.

2.Colored Optical Fiber

In order to distinguish each core of central tube fiber optic cable in communication engineering, optical cable queezed with a layer of colored plastic on the bare fiber. Outdoor optical cable is to dye each core of bare fiber with different colors of ink. The color of ink is the same as that of indoor cable, which is also 12 kinds. The color spectrum of the industry standard of the Ministry of Information Industry arranged as follows: blue, orange, green, brown, gray, natural (white), red, black, yellow, purple, pink, cyan. It allowed to use natural color instead of white without affecting identification.

3.Color-locked Optical Fiber

In order to protect the optical fiber, a layer of 250 microns of translucent resin is coated on the surface. When the optical fiber made into an optical cable, each core of the optical fiber needs to be dyed with a different color. Therefore, some foreign optical fiber manufacturers. During production, the optical fiber coated with 12 different colors of resin. In this way, the optical cable factory does not need to color it when using it. The advantage of doing so is that it saves a coloring process, but the disadvantage is that it cannot be used flexibly.

4.Water-blocking Tape

The water-blocking tape made of two layers of non-woven fabric with water-blocking powder added between them. Once the optical cable enters water, the powder will expand rapidly by dozens of times after absorbing water. A jelly-like gel is produced to prevent water from spreading deeper into the optical cable.

5.Non-woven Fabric

Some manufacturers will use non-woven fabrics that are much cheaper than water-blocking tapes to replace water-blocking tapes to reduce costs. There is no difference in appearance. Once the outer skin of the optical cable is broken, the non-woven fabric cannot block water.

6.Corrugated Steel Belt

The water-blocking tape is wrapped with corrugated steel belt. The main function of the steel belt in the optical cable is to resist lateral pressure, tension, prevent rat bites, and protect the bundle tube.

7.Steel Wire

We see two parallel steel wires outside the steel belt. The function of the steel wire is to enhance the tensile force of the optical cable. The gray steel wire on the surface is phosphated. The silver steel wire is galvanized. It prevents the steel wire from rusting. Galvanized steel wire is more expensive than phosphated steel wire.

8.Cable Sheath

Outdoor optical cables generally use medium-density polyethylene (MDPE). Some customers also specify high-density polyethylene (HDPE). The cost of using high-density PE is slightly higher. Some orders also specify low-smoke zero-halogen material (LSZH) as the sheath.