Shanghai Gengyun Industrial Co., Ltd

What is SC APC Connector? Installation of SC APC connector

Every aspect of fiber optic interconnection technology reflects its key features such as efficiency and reliability. SC APC connector, as one of the best connectors, determine the needs of many areas of telecommunications and data transmission. I believe that after reading this article, you will have a deep understanding of what is sc apc connector.

What is sc apc connector?

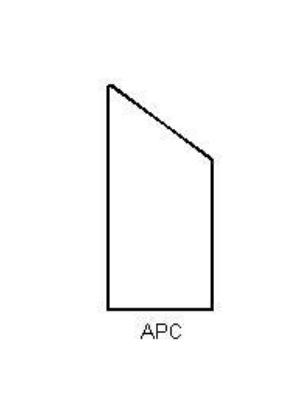

SC APC connector have angle polished ferrule end faces. This allows the fibers to connected with considerable accuracy and minimize losses. SC is a user connector. It is linear in form but uses push-pull coupling for easy installation and removal. APC stands for angle physical contact. Basically, the fiber end face polished at an 8-degree angle to reduce back-reflected noise and improve signal quality. This type of connector is used in high-bandwidth applications. For example, FTTH (Fiber to the Home), CATV, and data communication networks.

SC (User Connector) is classified as a fiber optic connector with a push-pull mechanism for easy installation and removal. It has a rectangular body and uses a snap-fit procedure to lock the connector in place. The connector characterized by low insertion loss and extremely high repeatability, which makes it particularly suitable for telecommunications and data communication applications. SC connectors equipped with 2.5mm ferrules and are very reliable for interconnection in network systems.

Features of APC Polishing

Polishing with angled physical contact (APC) is useful in various aspects by limiting back reflections. This is very important when dealing with high power and high frequency applications where signal quality is critical. The fiber end face angled at 8 degrees and this basic feature of polishing also prevents micro reflections from the fiber core. Because the excess light refracted into the cladding. This can proportionally reduce the optical return loss ORL and improve the entire network.

Some important parameters of APC connectors

-

Return loss

In general, these values are greater than 60 dB. Much greater than the return loss in the case of UPC (Ultra Physical Contact) connections (about 50 dB).

-

Insertion loss

In most cases, this value is low, about 0.2 to 0.3 dB. This means no signal loss or very little signal loss.

-

Durability

Good resistance to dirt and mechanical degradation. It can operate for many years even in demanding applications.

In addition, due to the design, such connectors do not cause connection fluctuations. This is particularly true in dense wavelength division multiplexing (DWDM) and passive optical networks (PON). These characteristics make the typical intraclconnector APC polished connector an indispensable part of modern optical communication system installations.

Application of APC Connectors in Single-mode Networks

When it comes to single-mode fiber networks, the use of APC polished connectors is particularly beneficial. Because they help reduce a lot of back reflections of interfering signals. In most cases, this type of network is suitable for high-bandwidth and long-distance data transmission, which can be steadily enhanced by using APC connectors. This type of connector produces minimal insertion loss and high return loss. Therefore, it can improve transmission efficiency.

APC polished single-mode connectors are essential in high-precision environments that have low tolerance for signal attenuation. For example, telecommunications, data centers, and long-distance networks. They allow high-speed applications to operate optimally and improve network performance as the demand for high-capacity communication infrastructure increases. This makes the use of APC connectors in advanced single-mode fiber networks a necessity.

Installation and Maintenance of SC APC Connector

-

Prepare fiber optic cables

With the help of a special fiber stripping tool, strip the outer protective jacket of the fiber optic cable.

Use a lint-free cloth and some alcohol to remove dirt from the surface of the fiber.

-

Cut the fiber

Insert the cleaned fiber into the precision fiber cleaver device.

Perform the cut to produce a flat, smooth end face.

Transfer the cut fiber to the SC/APC connector.

Insert the cut fiber into the rear of the SC/APC connector.

Push the fiber in and shake it gently until it is fixed in place with a “click”.

-

Cure Epoxy

Epoxy is optional, but if you want to use it, you can add a small amount of epoxy to the fiber before inserting it into the bracket.

Place the connector in a curing oven according to the curing specifications of the connector model equipment manufacturer.

-

Polish the Glass of the SC/APC Connector

When the epoxy cured, remove the excess extended fiber with the help of a scribing tool.

The end face of any plastic connector polished with a polishing film to ensure a smooth surface.

-

Inspect the Connector

A microscope can used to check for any defects or dirt on the polished connector end face.

If there are any problems, clean the connector and re-polish if necessary.

-

Test the Connector

Test the installed connector using an optical time domain reflectometer (OTDR), power meter and find out the results.

Check if the specified values of insertion loss and return loss are within the acceptable range.

-

Install the Fiber Optic Cable Assembly

Bin the installed SC/APC terminal to the appropriate panel or equipment.

If possible, secure the cable to minimize stress and strain.

By following these steps, the SC/APC plug connector will meet high installation quality and reliability standards when used in conjunction with fiber optic installations.