Shanghai Gengyun Industrial Co., Ltd

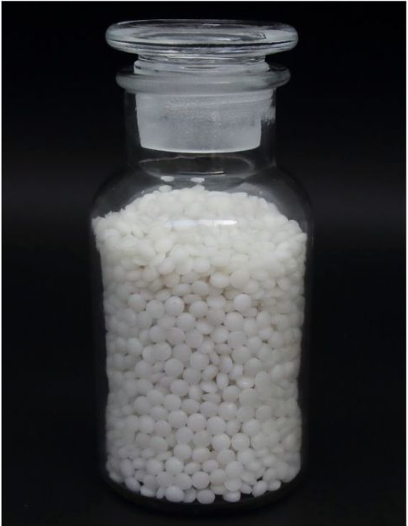

plastic particles

There are roughly six categories Plastic Recycling Granulator of common recycled plastic particles

PP recycled plastic particles: namely polypropylene particles. When not colored, it appears semi transparent, waxy, And lighter than polyethylene; Transparency is also better and harder than polyethylene.

PE recycled plastic pellets: i.e. polyethylene pellets. When not colored, it appears milky white and semi Transparent wax like, With a smooth feeling when touched By hand. It is soft and tough, and can stretch slightly.

PS recycled plastic particles: namely polystyrene particles. Simple coloring and goodtransparncy, commonly used for manufacturing lampshades, toothbrush handles, toys, and electrical components.

PVC recycled plastic particles: i.e.Polyvinyl chloride Particles. Colorful, corrosion-resistant, and sturdy.

ABS recycled plastic particles: are plastic particles polymerized from acrylonitrile, butadiene, and styrene.

PA recycled plastic pellets: namely nylon plastic pellets. Characterized by toughness and wear resistance, it is commonly used to manufacture plastic textured combs, toothbrushes, clothes hooks, and fan bones.

Plastic Recycling Particles: Not all plastics can be recycled

Recycled particles are particles extracted from plastic waste and produced after processing. The production process of regenerated particles mainly includes the following steps:

1. Waste pretreatment: sorting, cleaning, crushing and other treatments are carried out on plastic waste to turn it into granular material.

2. Plastic melting: Melt the pre treated plastic and process it into recycled particles through specific machines.

3. Particle screening: Screen and classify the regenerated particles produced to obtain particles that meet the requirements.

What are the components of recyclable plastic bottles

Recyclable plastic bottles are an excellent packaging material, mainly Made of materials such as polyethylene, polypropylene, and polyethylene terephthalate. This type of plastic bottle is loved by people because it is lightweight, easy to carry, has good preservation performance, is safe and hygienic, and can be recycled. In daily use, it is important to pay attention to reasonable use and disposal, and actively participate in the utilization of recyclable resources and environmental protection actions.

Plastic pellets have a wide range of applications in multiple industries, mainly reflected in the following aspects

1: Products: Grains are the basic raw materials for producing various plastic products. Through injection molding, blow molding and other processes, plastic particles can be made into plastic bags, bottles, buckets, films, tables and chairs, toys, electrical casings, etc. These products are widely used in daily life, industrial production, agriculture and other fields.

2: Materials: In the construction industry, plastic pellets are used to manufacture building components, construction tools, plastic doors and windows, mud and ash buckets, etc. Plastic materials have characteristics such as weather resistance, corrosion resistance, waterproofing, and insulation, which can meet various needs of buildings. In addition, plastic pellets can also be used to make insulation and fire-resistant materials, improving the energy efficiency and safety of buildings.

3: Material: Plastic pellets are widely used in the packaging of food, medicine, and daily necessities. Plastic packaging containers made through injection molding, blow molding and other processes, such as bottles, boxes, bags, etc., have excellent sealing and preservation properties, which can effectively protect the quality and safety of products.

4: Industry: Components made of plastic pellets are extensively used in Modern automobiles, such as the body, interior, engine hood, etc. Plastic particles have the characteristics of light weight, good wear resistance, and good sound absorption performance, which can improve the fuel efficiency of cars, reduce noise and vibration, and enhance ride comfort.

5: Electrical industry: Plastic pellets can be used to make casings, accessories, cables, etc. in electronic products. Plastic particles have the characteristics of good insulation performance, high temperature resistance, corrosion resistance, etc., which can protect the normal operation and safety of electronic appliances.

6: Industry: After special formulation, plastic particles can be used to manufacture machine components such as various forms of bearings, gears, camshafts, eccentric wheels, sealing rings, various blades, various water pump impellers, etc.

7: Industry: In the chemical industry, plastic particles can be used to make reaction vessels, pipelines, containers, pumps, valves, etc., and are applied in chemical Production sites to solve Corrosion and wear Problems.

Agriculture: Plastic pellets are used in agriculture to Manufacture agricultural films, water pipes, agricultural Machinery, fertilizer packaging bags, cement packaging bags, etc. This provides sustainable packaging and tool options for agriculture, While reducing the Demand for new plastics.

8: Equipment: Plastic pellets are also used in medical devices.

Refining and Fuel: Particles made from plastic waste can be used for refining, grinding, and as alternative fuels.