Shanghai Gengyun Industrial Co., Ltd

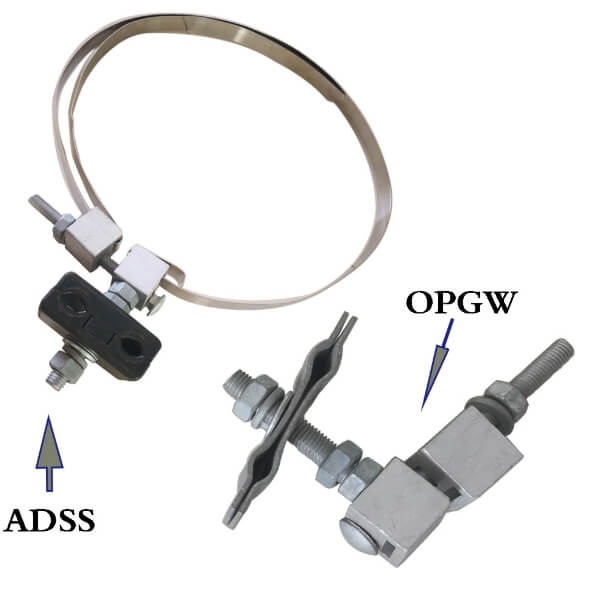

Introduction of Opgw Drop Wire Clamp

What is an OPGW drop wire clamp? It mainly used for the fixed installation of ADSS*/OPGW* optical cables when they are led on poles and towers. For example, at the optical cable joint pole (tower). The optical cable fixed from the clamping hardware to the installation of the splice protection box. The fiber optic cable fixed when it is led from the pole tower to the underground pipeline, cable trench, direct burial. And led down to the machine room. It prevents the optical cable from being damaged by friction with the pole tower or other objects under the action of wind, so as to protect the safety of the optical cable.

TOEM can provide the following types of down-lead clamps, namely: tower-type down-lead clamps and pole-type down-lead clamps.

Features of OPGW Drop Wire Clamps

The insulated opgw drop wire clamp is a cable clamp. Which is an insulated down-lead clamp for optical fiber composite overhead ground wire. It includes a connection fitting 1, a composite insulator +, a connection fitting 2, an S-type fixing clamp or a pole clamp and a wire tie. One end of the composite insulator is equipped with a connection fitting. 1. And the other end is equipped with a connection fitting 2. The end of the connection fitting 2 is equipped with an S-type fixing clamp or a pole clamp.

The two ends of the wire tie are spiral-shaped. And a bayonet is provided in the middle of the wire tie to fix with a connection fitting. The composite insulator includes a core rod and a skirt. And the core rod installed in the skirt. The core rod and the skirt made of insulating materials. The pole clamp includes an upper clamp and a lower clamp. The utility model has the advantages of firm installation and convenient operation. It is used to fix the optical cable for connection and down-leading to avoid friction between the optical cable and the tower during operation. And the optical cable is insulated from the pole tower.

Purpose of OPGW Downlead Clamp

OPGW drop wire clamp used to fix OPGW/ADSS on pole towers. And to fix optical cables when they are led down and jumpered. One set is required for every 1.5-2.0 meters of optical cable. It is suitable for different cable diameters, easy and reliable to install, and has a wide range of adjustment.

Downlead clamp mainly used for the fixed installation of ADSS and OPGW optical cables when they are led on pole towers. For example, at the optical cable joint pole (tower), the optical cable fixed from the clamping hardware to the installation place of the splicing protection box. The optical cable fixed from the pole tower to the underground pipeline, cable trench, direct burial, and down to the machine room. Avoid the optical cable from rubbing against the pole tower or other objects under the action of wind and damaging the optical cable to protect the safety of the optical cable.

Installation of OPGW Drop Clamp

All optical cable downleads are led down from the tower legs as required by the design, along the crossbar to the junction box. To prevent the optical cable from generating a golden hook when it is led down. The lead-down wire clamp should installed every 1.5-2 meters in principle or according to the design of the optical cable. However, when the optical cable lead-down wire turns and the optical cable turning radius needs to be met. The lead-down wire clamp can be added according to the actual situation to fix the lead-down wire.