Shanghai Gengyun Industrial Co., Ltd

GYTC8S Optical Fiber Cable: Applications and Advantages

GYTC8S optical fiber cable is a high-performance outdoor communication cable widely used in modern telecommunication networks. Combining robust mechanical properties with exceptional environmental resilience, it has become a cornerstone for long-haul and metropolitan network deployments. This article explores the structural design, key applications, technical advantages, and comparative benefits of GYTC8S cables, emphasizing their role in advancing global connectivity.

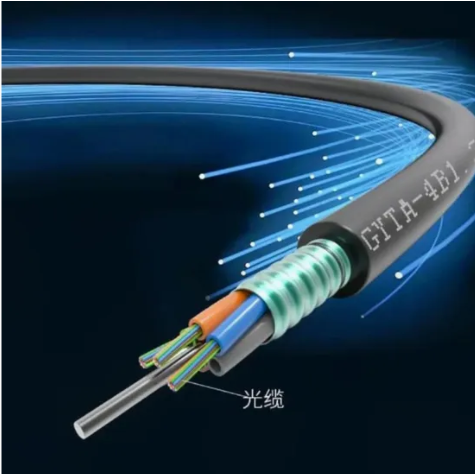

Introduction to GYTC8S Optical Fiber Cable

The GYTC8S cable is a standardized optical fiber cable designed for outdoor environments. Its nomenclature follows industry conventions:

- GY: Denotes an outdoor (“tough”) communication cable.

- T: Indicates a filled cable structure with water-blocking compounds.

- C8: Refers to 8-layer corrugated steel tape armoring.

- S: Represents a polyethylene (PE) outer sheath.

This structure ensures durability, waterproofing, and resistance to mechanical stress, making it suitable for harsh terrains and extreme weather conditions.

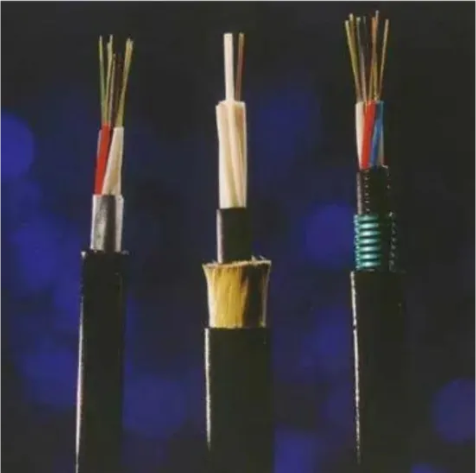

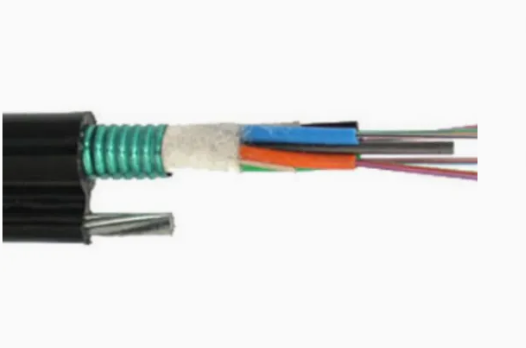

Structural Design and Material Composition

The superior performance of GYTC8S stems from its layered architecture:

2.1 Core Components

- Optical Fibers: Typically single-mode (G.652.D) or multimode fibers housed in loose tubes.

- Loose Tubes: Up to 12 tubes filled with water-blocking gel to protect fibers from moisture.

- Central Strength Member: A steel wire or fiber-reinforced plastic (FRP) rod provides tensile strength.

- Armor Layer: Double-layer corrugated steel tape (C8) offers crush resistance and rodent protection.

- Outer Sheath: High-density polyethylene (HDPE) resists UV radiation, chemicals, and abrasion.

2.2 Key Design Features

- Waterproofing: Gel-filled tubes and moisture-resistant tapes prevent water ingress.

- Flexibility: Corrugated armor allows bending without compromising structural integrity.

- Temperature Range: Operates between -40°C to +70°C, ideal for extreme climates.

Applications of GYTC8S Cable

GYTC8S cables are deployed in scenarios demanding reliability and longevity:

3.1 Long-Haul Backbone Networks

- Cross-Continental Links: Used in undersea and terrestrial backbone networks due to low signal attenuation (<0.22 dB/km at 1550 nm).

- Railway and Highway Projects: Installed alongside transport corridors for stable connectivity.

3.2 Metropolitan Area Networks (MANs)

- Urban Infrastructure: Buried or duct-laid in cities to support 5G backhaul and FTTH (Fiber-to-the-Home) deployments.

- Smart City Projects: Facilitates IoT sensor networks and traffic management systems.

3.3 Harsh Environments

- Mountainous Regions: Resists landslides and temperature fluctuations.

- Coastal Areas: Corrosion-resistant armor prevents saltwater damage.

3.4 Industrial Zones

Power Plants and Oil Refineries: Withstands electromagnetic interference (EMI) and chemical exposure.

Technical Advantages of GYTC8S

GYTC8S outperforms conventional cables (e.g., GYTA, GYTS) in multiple aspects:

4.1 Mechanical Strength

- Tensile Strength: Supports up to 6,000 N during installation.

- Crush Resistance: Steel armor withstands 3,000 N/cm pressure, critical for direct burial.

4.2 Environmental Resilience

- Waterproofing: Passes IEC 60794-1-F1 immersion tests.

- UV and Weather Resistance: PE sheath maintains flexibility after prolonged sun exposure.

4.3 Installation Flexibility

- Bending Radius: Minimum 20× cable diameter for easy routing.

- Lightweight Design: Approximately 20% lighter than fully armored cables, reducing installation costs.

4.4 Long-Term Reliability

- Lifespan: Exceeds 25 years with minimal maintenance.

- Future-Proofing: Compatible with DWDM and 400G+ transmission systems.

Comparative Analysis with Other Cables

A comparison of key features among GYTC8S, GYTA, and GYTS cables is summarized below:

- Armor Type: GYTC8S uses corrugated steel, GYTA uses aluminum tape, and GYTS uses steel wire.

- Weight: GYTC8S is moderate, GYTA is light, and GYTS is heavy.

- Crush Resistance: GYTC8S offers excellent resistance, GYTA good, and GYTS very good.

- Cost Efficiency: GYTC8S is highly cost-efficient, GYTA moderate, and GYTS low.

- Ideal Use Case: GYTC8S suits harsh environments, GYTA urban ducts, and GYTS areas with high rodent risk.

GYTC8S strikes a balance between cost, durability, and adaptability, making it a versatile choice for diverse projects.

Case Study: GYTC8S in the Himalayas

A 2022 project in Nepal deployed GYTC8S cables to connect remote villages. Challenges included:

- Temperature swings (-30°C to +45°C).

- Frequent landslides and wildlife interference.

Outcome: - Zero fiber breaks over 150 km.

- Achieved 99.999% uptime in 18 months.

Future Prospects

Emerging trends will further elevate GYTC8S relevance:

- 5G Expansion: Demand for robust backhaul solutions.

- Climate Resilience: Reinforced designs for flood-prone regions.

- AI-Driven Networks: Compatibility with predictive maintenance systems.

Conclusion

GYTC8S optical fiber cable is a testament to innovation in telecommunication infrastructure. Its unparalleled mechanical strength, environmental adaptability, and cost efficiency position it as a critical enabler of global connectivity. As networks evolve, GYTC8S will remain indispensable in bridging the digital divide, from urban hubs to the world’s most challenging terrains.

For further guidance or to explore our range of high-quality fiber optic solutions. Visit TOEM and MIC TOEM, optical communications is our specialty.