Shanghai Gengyun Industrial Co., Ltd

Fusion Splicer, Optical Fiber Splicer, Fiber Splicer Automatic Core Alignment, Portable, Kit

Fiber optic splicer, also known as fiber optic welding machine, is used for A high-precision device that fuses two optical fibers to form a permanent and low-loss connection. It is the core tool for the construction, maintenance and upgrading of modern optical fiber communication networks and is hailed as the “sewing expert” in the field of optical communication.

Introduction to core advantages

Extremely low splicing loss: This is the most core advantage of the optical fiber splicer. By using a high-voltage arc to instantly melt the end faces of two optical fibers and precisely connect them, the signal loss at the connection point can be controlled below 0.03dB, or even lower. This is far superior to mechanical connection methods, ensuring the efficiency and stability of optical signal transmission, and providing a solid foundation for high-speed broadband and 5G networks.

High strength and stability: The connection point formed by fusion is essentially an integrated glass body, with mechanical strength similar to that of the optical fiber itself. After being protected by heat shrink tubing, the joint can withstand vibration, temperature changes and long-term aging. Its service life is the same as that of optical fibers, greatly reducing the need for future maintenance.

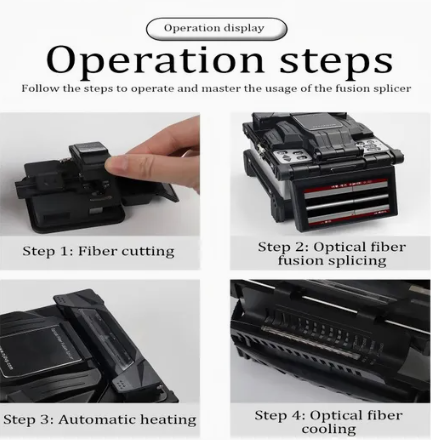

High efficiency and intelligence: Modern fusion splicers are highly automated. The operator only needs to place the stripped and cleaned optical fibers into the fixture, and the machine can automatically carry out a series of steps such as optical fiber alignment, gap setting, end face inspection, discharge splicing and loss estimation. The entire process only takes about ten seconds, significantly enhancing the construction efficiency and reducing the excessive reliance on the skills of the operators.

Widely applied and highly adaptable: From long-distance trunk lines in the backbone network, to FTTH fiber to the home on the user side, and even to internal cabling in data centers, fiber fusion splicers are everywhere. It can handle various types of 3.3 optical fibers such as single-mode and multi-mode, and can also address the splicing challenges in special environments (such as high altitudes and extremely cold regions) through dedicated programs.

In conclusion, the fiber optic splicer, with its features of low loss, high reliability, and intelligent efficiency, has become an indispensable key device for building and maintaining the global information superhighway. It is the unsung hero that ensures we enjoy a high-speed and stable network experience.

Keywords:

1:Automatic fiber core alignment optical fiber splicing machine

2:Portable optical fiber fusion splicer kit

3:A complete set of tools for optical fiber splicing machines