Shanghai Gengyun Industrial Co., Ltd

Manufacturing Optical Fiber Raw Material High Purity Quartz Optical Fiber Preform Rod

Today, when information is transmitted at the speed of light, optical fiber networks have become the arteries of the global digital economy. And all of this began with a core material – high-purity quartz optical fiber preforms. That can be used to make communication optical fiber of “ mother material“, its outstanding performance directly decide the final fiber products of transmission capacity, reliability and longevity.

Core advantages overview:

Ultra-low transmission loss ensures efficient long-distance transmission of signals: Manufactured by advanced processes such as chemical vapor deposition, the preform has extremely high internal purity, with the content of impurity metal ions controlled at the parts per billion level. This ultimate purity can minimize the scattering and absorption of optical signals during transmission, achieving an astonishingly low attenuation coefficient and laying a physical foundation for long-distance and high-capacity communication.

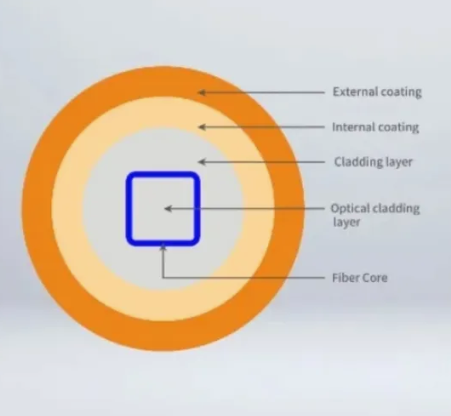

Outstanding bandwidth and consistency support high-speed data flows: The precisely controlled refractive index profile structure endows optical fibers with extremely high bandwidth characteristics, enabling the transmission of massive data without distortion. Meanwhile, the high consistency of geometric dimensions and optical uniformity ensure that each optical fiber has stable and reliable performance, meeting the strict requirements for speed and stability of 5G, data centers and future networks.

Extraordinary mechanical strength and environmental durability: High-purity synthetic quartz itself possesses excellent tensile strength and resistance to micro-bending , enabling optical fibers to withstand harsh laying environments and long-term usage stresses. Its inherent physical and chemical stability can more effectively resist moisture erosion and temperature changes, ensuring the stable operation of the network for decades under complex geographical and climatic conditions.

Product and Application Introduction

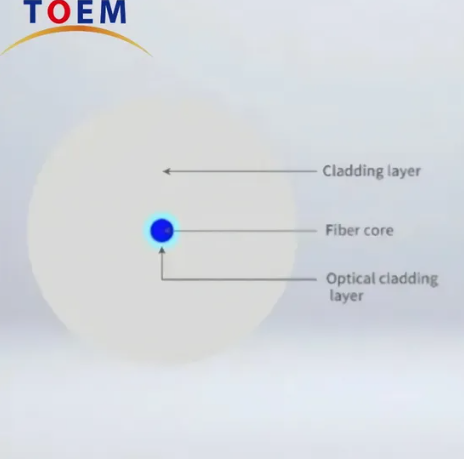

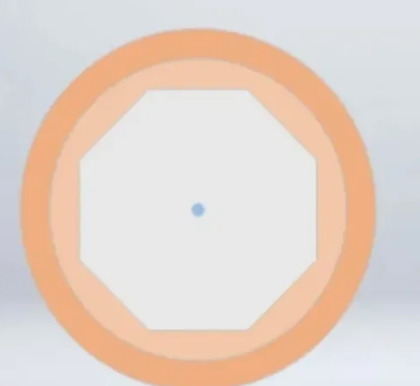

optical fiber preform is through the ultra pure gas (such as four chloride silicon) in high temperature under on oxidation reaction, forming a fine of dioxide quartz glass dust, and step by step a deposit in the target bar or tube, A solid glass rod precisely sintered. This process precisely constructs the core and cladding structure of optical fibers, and it is the link with the highest technical barrier and the most concentrated value in optical fiber manufacturing.

It is not only the manufacturing standard communication single-mode/more mode optical fiber the cornerstone, is the special optical fiber (such as used for optical fiber laser, ocean sensing, medical equipment of high power, mixed rare earth elements in optical fiber)is indispensable of the starting point. From transoceanic optical cables to urban access networks, from aerospace to smart grids, its outstanding performance is quietly supporting the operation of the entire modern information society.

In conclusion, high-purity quartz optical fiber preforms, with their ultra-low loss, ultra-high bandwidth and extraordinary reliability, have become irreplaceable core raw materials in the field of optical communication. It is not only a manifestation of technological progress but also a solid bridge connecting the future digital world.

Keywords: