Shanghai Gengyun Industrial Co., Ltd

What is FTTH Bend Insensitive Optical Fiber? A Guide for Last-Meter Reliability

Solving the Final Challenge in FTTH

Fiber-to-the-Home (FTTH) deployment presents a unique challenge in its final stage. Here, fibers must navigate a complex, tight environment. Installers bend them around sharp corners, pull them through narrow conduits, and tuck them into small boxes. Under these small bend radius conditions, standard single-mode fiber can suffer major macro-bend loss, weakening the signal and degrading service quality. Bend-insensitive fiber (BIF) solves this problem. This specialized fiber, often built into flexible indoor drop cables, is key for creating robust and installer-friendly final connections.

- The Critical Importance of the “Last Meter”

An FTTH network is only as good as its final link. After kilometers of straight outdoor cable, the signal must navigate the tricky final few meters inside a home. Installers face time pressure and physical limits. Bend-sensitive fibers force them to create perfect, wide loops—often impossible in real homes. Bend-insensitive fiber gives installers a vital performance margin, turning potential failure points (like tight bends behind furniture) into non-issues. This results in higher installation success rates, fewer service calls, and a better customer experience.

- Evolution from Standard to Bend-Insensitive Fiber

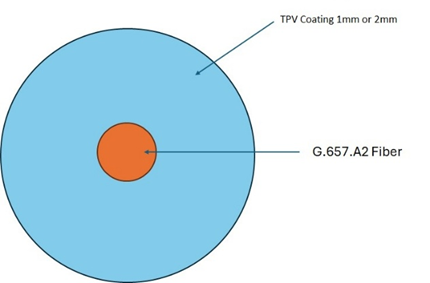

Standard single-mode fiber (ITU-T G.652) is made for long, straight runs, with light loosely confined in its core. Sharp bends cause light to leak out, creating signal loss. The industry developed Bend-insensitive fiber, standardizing it as ITU-T G.657. Engineers redesigned the fiber’s internal waveguide structure, modifying the refractive index profile to create a light “trap” that holds light tightly to the core, even during sharp curves.

Technical Innovation and Key Performance

BIF achieves exceptional bend resistance through intelligent optical design. Its performance is standardized and measurable.

- Waveguide Design: The Low-Index Trench

The most common and effective design features a low-index trench (or ring) in the cladding around the core. This trench, with a refractive index lower than the outer cladding, acts as a barrier that reflects escaping light back toward the center. This smart structure allows the fiber to maintain extremely low bend loss under conditions that would severely degrade standard fiber. Categories like G.657.A1, A2, and B3 offer progressively better performance for different needs.

- Measuring Bend Performance: The 10mm and 5mm Test

Rigorous testing standards define bend resistance. For common G.657.A1 fiber, the standard specifies maximum added loss of ≤ 0.5 dB when wrapped 100 times around a 30mm rod, and ≤ 0.1 dB for one turn around a 15mm rod. More advanced fibers can handle 5mm bends or smaller with negligible loss. This allows installers to staple the cable, wrap it tightly, or coil it in tiny enclosures without worrying about signal loss at key wavelengths like 1310nm, 1490nm, and 1550nm.

- Full Compatibility with Existing Networks

A critical feature of BIF is backward compatibility. While its bend performance is superior, its basic transmission traits in a straight line—such as attenuation and mode field diameter—match standard G.652.D fiber. This ensures seamless splicing and connectivity within existing networks, requiring no special tools or adapters.

Application in FTTH Drop Cables and Deployment

Bend-insensitive fiber typically serves as the core of a complete drop cable assembly designed for indoor use, delivering real system-level value.

- The FTTH Drop Cable Assembly

A standard indoor FTTH drop cable contains:

- The Fiber: One or two G.657.A1/A2 bend-insensitive fibers.

- Strength Members: Aramid yarns (like Kevlar®) that provide tensile strength.

- The Sheath: A soft, flexible, and durable PVC or LSZH jacket, often bright orange for visibility. This softness ensures easy handling and allows the cable to lie flat.

The result is a lightweight, highly flexible cable that is simple to terminate with field-installable connectors (like SC/APC) and routes easily along baseboards.

- Deployment Workflow and Key Benefits

During a typical FTTH installation:

- The technician runs the drop cable from outside into the home.

- They route it to the Optical Network Terminal (ONT) location.

- They secure the cable, often creating tight bends.

- Finally, they connect the fiber to the ONT.

Using bend-insensitive fiber provides major benefits: it reduces installation time, increases first-time success rates, and provides a higher optical power budget margin at the ONT for long-term stability.

The Future: Tougher and Smarter Drop Solutions

As FTTH expands, innovation will focus on meeting greater demands on the final connection.

Future development targets even tougher fibers (like G.657.B3) capable of withstanding extreme sub-2mm bends for complex wiring. Cable designs are also becoming more rugged. The industry is moving toward factory-pre-connectorized drop cables for plug-and-play installation, where BIF is essential as cables ship coiled. In Multi-Dwelling Units (MDUs), BIF enables dense, flexible routing to support future upgrades.

In conclusion, FTTH Bend Insensitive Optical Fiber is a fundamental enabler for reliable and economical FTTH deployment. By solving the critical challenge of macro-bend loss, it empowers installers, reduces costs, and safeguards service quality. Its compatibility and role in flexible drop cables make it indispensable for delivering high-speed broadband reliably to the final connected device.

FAQs

1. Can I mix bend-insensitive fiber (G.657) with standard fiber (G.652) in one network?

Yes, this is standard and recommended practice. G.657 fiber is fully compatible with G.652.D fiber. They can be fusion spliced together using standard methods with low loss. Typically, the network backbone uses standard fiber, and bend-insensitive fiber is used only in the final indoor drop segment. This applies the advanced fiber only where it’s needed, keeping costs optimal.

2. Is bend-insensitive fiber more expensive?

The fiber itself has a modest cost premium due to more complex manufacturing. However, when considering total cost of ownership, it saves money. It reduces installation time, cuts down on failures and service calls, and prevents customer complaints from bent cables. The savings in operational efficiency and service quality far outweigh the slightly higher material cost.

3. Does bend-insensitive fiber require special splicing or connectors?

No. The fiber’s external dimensions and core alignment are identical to standard fiber. You use the same fusion splicer programs, the same mechanical splices, and the same connectors (SC, LC, etc.). The bend-resistant feature is internal to the glass and does not change the termination process.

4. Are there different grades, and how do I choose?

Yes, defined by ITU-T G.657 categories:

- G.657.A1: The most common choice for general home drops. Excellent performance for bends down to 10mm radius.

- G.657.A2: Better performance (down to 7.5mm radius), for very challenging indoor routes or apartment buildings.

- G.657.B3: Highest performance for extreme bends (down to 5mm radius), used in very dense wiring or specialized equipment.

For most residential FTTH, G.657.A1 offers the best balance of performance and value.

Company Introduction: With over 20 years of deep industry expertise, we specialize in customizing and supplying solutions for optical fibers, cables, raw materials, and manufacturing equipment. We deliver reliable technical support and product services.

About the Author: With 20 years of hands-on experience in optical transmission media, cable assemblies, and core substrate materials, we offer practical, expert insights grounded in full-industry-chain expertise.