Shanghai Gengyun Industrial Co., Ltd

What is GY(B)JA LSZH Waterproof Optical Cable? A Guide to Safe Indoor Cabling

The Need for Safety in Dense Indoor Networks

Modern structured cabling systems pack many wires and cables inside buildings. Areas like data center rooms, building vertical risers, and equipment closets are especially dense. In these environments, two factors are critical: fire safety and efficient space use. Fires can spread quickly through cable trays, and toxic smoke often proves more dangerous than flames. The GY(B)JA indoor optical cable is a specialized solution for these challenging spaces. This engineered product provides reliable fiber optic protection while prioritizing safety and environmental responsibility.

- Decoding the Cable Name: What Does GY(B)JA Mean?

The name GY(B)JA follows a common industry model code. Breaking it down reveals its purpose:

- GY: Signifies a “Telecommunication Cable” base model, with indoor optimization.

- (B): Indicates a specific structural variant, like a central tube design.

- J: Denotes an indoor optical cable for building use.

- A: Often signifies a performance class, here linked to the LSZH sheath.

This naming tells us it’s a telecom-grade indoor cable designed with specific safety features, differentiating it from standard variants.

- The Core Challenge: Balancing Safety, Performance, and Space

Designing cable for dense indoor areas is complex. Engineers must balance several demands:

- Fire Safety: The cable must resist ignition, limit flame spread, and minimize harmful emissions.

- Space Efficiency: A smaller outer diameter and lighter weight are essential for high-density management.

- Reliability: The cable must protect delicate glass fibers from mechanical stress and threats like moisture.

- Installation Ease: It needs flexibility for pulling through conduits and trays without damage.

The GY(B)JA cable successfully integrates all these requirements into one design.

Technical Design: Materials and Construction for Superior Safety

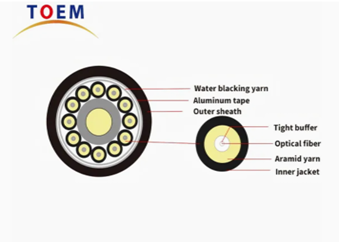

The superior performance of the GY(B)JA cable comes from thoughtful material selection and internal structure. Every layer serves a specific protective function.

- The Life-Saving Sheath: LSZH Material Explained

The most critical feature is its outer sheath made from Low Smoke Zero Halogen (LSZH) compound. This material provides a triple safety benefit in case of fire:

- Flame Retardancy: It resists ignition and slows flame spread along cable trays.

- Low Smoke Emission: It produces significantly less smoke than standard PVC cables, maintaining visibility for evacuation and firefighting.

- Zero Halogen: It does not release corrosive, toxic halogen gases when burned, protecting both people and sensitive electronics.

An LSZH sheath helps the cable meet stringent international fire safety standards like the CPR (Construction Products Regulation) Euroclass.

- Internal Structure: Compact, Dry, and Protected

Inside the tough outer sheath, the cable uses a compact, efficient design. Common structures include:

- Central Tube Structure: Fibers sit in a single, central plastic tube filled with dry water-blocking compound.

- Stranded Structure: Multiple fiber subunits twist around a central strength member.

Both designs aim for a small cable diameter and light weight. The core uses dry water-blocking materials like water-swellable yarns, preventing longitudinal moisture migration from spills or humidity—hence the “waterproof” designation for an indoor cable.

- Optical Fiber and Mechanical Performance

The cable typically contains standard G.652.D single-mode fibers or multi-mode fibers, ensuring stable, low-loss transmission. It does not compromise on physical durability, meeting standard mechanical requirements for indoor cabling, including adequate tensile strength, good crush resistance, and a flexible bend radius.

Applications and Installation Best Practices

The GY(B)JA cable is designed for specific, safety-critical indoor pathways. Knowing where and how to use it is key.

- Primary Application Scenarios

This cable is ideally suited for:

- Data Center Interconnects: For links between server racks and in risers where density is extreme and fire codes are strict.

- Building Backbone Cabling: As the vertical riser cable connecting floors in offices, hospitals, or campuses.

- Horizontal Cabling in High-Risk Areas: In spaces with high people density, like airports, control rooms, or financial trading floors.

- Any Indoor Pathway with Strict Fire Codes: Where regulations mandate LSZH or low-smoke cables.

- Installation Guidelines for Optimal Performance

To ensure performance, follow these guidelines:

- Pathway Preparation: Ensure cable trays and conduits are free of sharp edges.

- Bend Radius Control: Adhere to the manufacturer’s specified minimum bend radius.

- Tension Management: Use appropriate pulling tools and do not exceed maximum pulling tension.

- Separation and Bundling: Avoid excessively tight bundling to maintain heat dissipation.

- Termination Handling: Use proper tools to strip the sheath without damaging internal materials.

Comparison and Strategic Value

Choosing the right cable involves understanding its comparison to alternatives and its long-term value.

- GY(B)JA vs. Other Common Indoor Cables

- vs. Standard PVC Indoor Cable: PVC is cost-effective but produces toxic smoke and gases. GY(B)JA LSZH is superior for life safety.

- vs. Outdoor Cable Used Indoors: Outdoor cables are over-built with heavy armor and gel, making them bulky and messy indoors. GY(B)JA offers a neat, lightweight, safety-optimized alternative.

- vs. Plenum Cable (CMP): In North America, plenum-rated cable is required for air-handling spaces. LSZH cables like GY(B)JA often meet or exceed these requirements and are a standard for high-safety applications globally.

- The Long-Term Value Proposition

Investing in GY(B)JA cable is an investment in risk mitigation. The initial cost may be higher than standard PVC, but it provides invaluable benefits:

- Enhanced Life Safety: Protects people by allowing safer evacuation and reducing toxin exposure.

- Asset Protection: Reduces the risk of corrosive gas damage to expensive equipment.

- Regulatory Compliance: Ensures adherence to strict international fire safety standards.

- Insurance Advantages: May lead to lower insurance premiums.

- Professional Reputation: Demonstrates a commitment to safety and quality in infrastructure.

In summary, the GY(B)JA LSZH Waterproof Optical Cable represents a sophisticated, safety-first approach to modern indoor network construction. It integrates a life-saving LSZH sheath with a compact, dry core, addressing fire hazard mitigation, space optimization, and reliable fiber protection. Its use in data centers, building backbones, and safety-sensitive areas provides crucial peace of mind, ensuring the network infrastructure itself does not become a liability.

FAQs

1. What is the main difference between LSZH and standard PVC cable sheaths?

The key difference is in their behavior during a fire. Standard PVC releases thick, black smoke and toxic, corrosive halogen gases. LSZH (Low Smoke Zero Halogen) material is specifically formulated to produce very little smoke and no halogen gases. This significantly improves visibility for escape and firefighting, and prevents secondary damage to equipment and harm to people from toxic fumes.

2. Since it’s called “waterproof,” can GY(B)JA cable be used outdoors?

No, it is strictly an indoor cable. Its “waterproof” or “water-blocking” feature refers to protection against longitudinal moisture (like spills or condensation along its length) within indoor environments. It lacks the robust armored protection, UV-resistant sheath, and full waterproofing required for direct burial or prolonged outdoor exposure. Always use a cable specifically designed and rated for outdoor use for exterior applications.

3. How does the dry water-blocking technology work compared to gel filling?

Traditional gel-filled cables use a sticky compound to block water. They can be messy to terminate and are less suitable for vertical runs indoors. Dry water-blocking technology uses special yarns or powders that rapidly expand upon contact with water, forming a seal. This method is cleaner, easier for installers to work with, and perfectly suited for the controlled risks of indoor settings, protecting against localized water ingress without the hassle.

4. Are there different fire rating classes for LSZH cables like this one?

Yes. Under standards like the EU’s Construction Products Regulation (CPR), cables are classified by “Euroclass.” Common classes for data cables include:

- B2ca: Very high contribution to fire safety.

- Cca: High contribution.

- Dca: Standard contribution.

The specific Euroclass of a GY(B)JA cable depends on its exact construction and testing. It’s crucial to specify the required fire performance class (e.g., Cca-s1a,d1,a1) for your project to ensure compliance with local building regulations.

Company Introduction: With over 20 years of deep industry expertise, we specialize in customizing and supplying solutions for optical fibers, cables, raw materials, and manufacturing equipment. We deliver reliable technical support and product services.

About the Author: With 20 years of hands-on experience in optical transmission media, cable assemblies, and core substrate materials, we offer practical, expert insights grounded in full-industry-chain expertise.