Shanghai Gengyun Industrial Co., Ltd

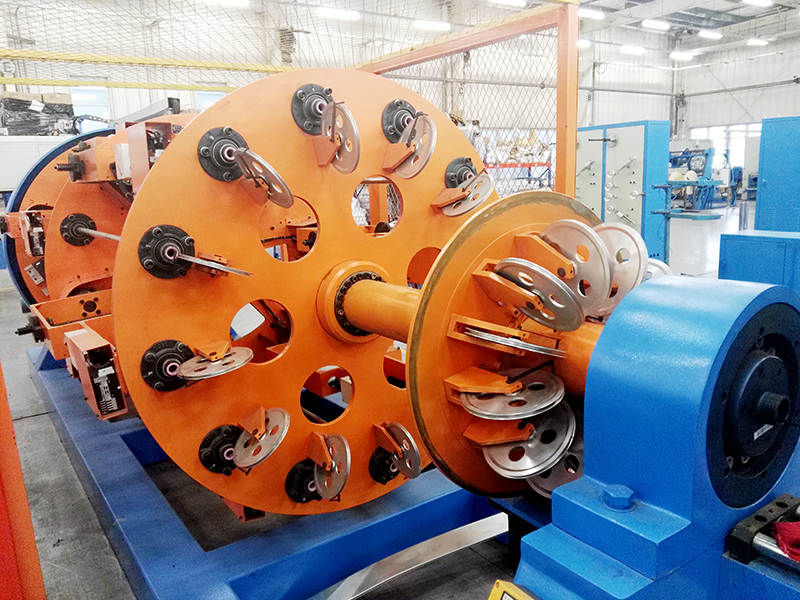

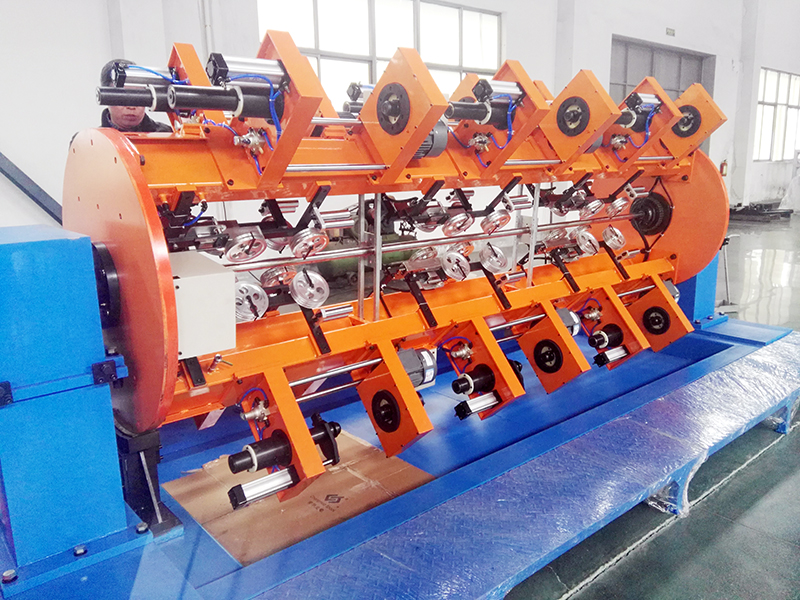

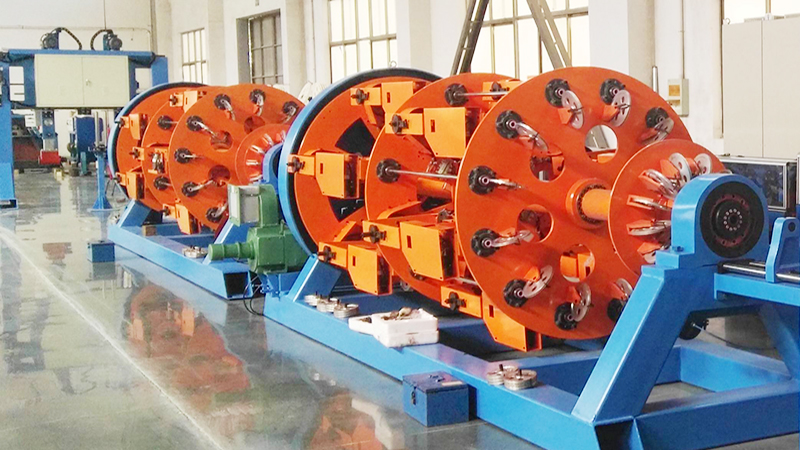

Fiber Optic Cable Cage Type Stranding Line

In the 1980s, the core manufacturing of various structural optical cables mostly used cage stranding machines, which were mainly characterized by uniform core stranding pitch, stable structure, and reliable performance. At that time, the cage stranding machine used a passive wire laying method of disc friction braking, and the tension of the wire laying increased and fluctuated greatly with the decrease of the distance from the output point of the laminating unit to the axis, which could lead to fluctuations in the excess length of the optical fiber. The current cage twisting cable laying machine adopts an active tension automatic control method for wire laying, effectively reducing the tension and its fluctuations. The miniaturized and lightweight tension control mechanism also reduces the rotational inertia of the rotating body, making it operate smoothly and increasing the winch speed.

| Technical Parameters Table of Typical Cage Type Stranding Line | |||

| Item

Name |

Unit | Specification | Remarks |

| Applicable disc tools for reinforcement wire laying device | — | Reinforcement and cable core tool tray | Implement multi-layer twisting |

| Reinforcement wire tension range | N | 20~300 | |

| Number of twisted cage units | 个 | 12 | |

| Specification of reinforced core and cable core tool tray | mm | PN630 | |

| Active unwinding of the twisting unit, tension range | N | 2~10 | |

| Maximum speed of the twisting cage | rpm | ≥100 | |

| Maximum cable core diameter | mm | φ35 | |

| Tie yarn pitch | mm | 20~40 | Continuous adjustable pitch |

| Tension range of yarn tying | N | 0.5~4 | Continuous and adjustable tension |

| Maximum traction force | N | ≥1200 | |

| Take-up reel tool | mm | PN1250~1600 | |

| Take-up tension | N | 5~300 | Continuous and adjustable tension |

| Maximum production speed | m/min | ≥25 | |