Shanghai Gengyun Industrial Co., Ltd

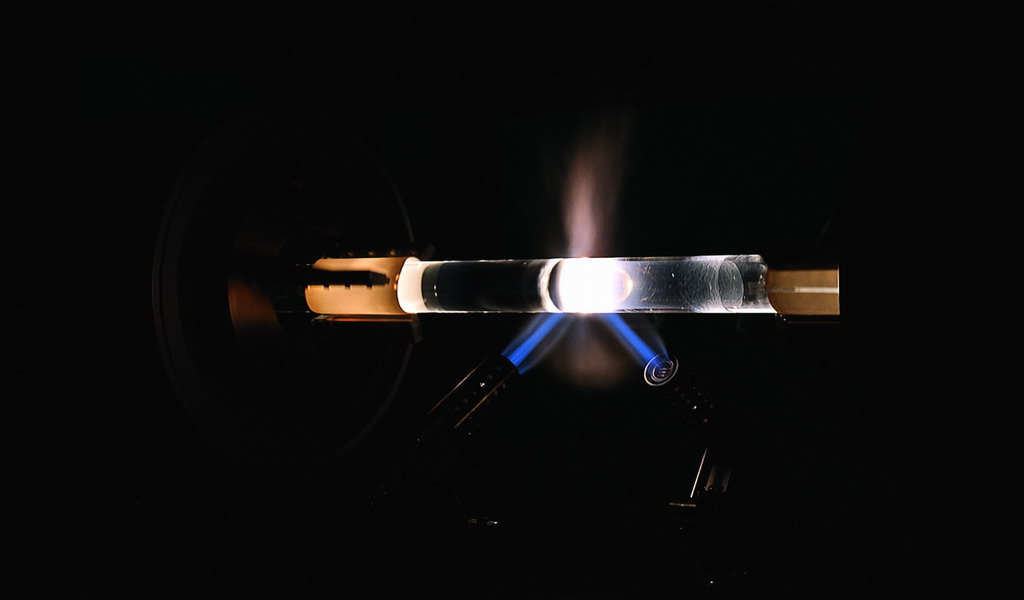

External Vapor Deposition (OVD) Device for Fiber

The External Vapor Deposition (OVD) process, also known as the External Vapor Deposition (OVD) process, was invented by Kapron et al. of Corning in 1972. The first optical fiber with a attenuation of less than 20dB/km was also prepared by Corning scientists using the OVD process. With the continuous advancement of technology, the OVD process has evolved from single nozzle deposition to simultaneous deposition of multiple nozzles; Depositing a single device

The development of fiber optic preforms has led to the simultaneous deposition of multiple preforms, significantly improving production efficiency and reducing production costs. The OVD process has the advantages of fast external deposition speed, large preform size, and low cost; At the same time, precise control of refractive index profile is achieved through layer by layer deposition, and various types of optical fibers are prepared by doping Ge, B, F, P and other dopants to achieve the desired profile. The OVD process is a typical powder method, which can obtain fiber preforms with extremely low impurity content through dehydration and impurity removal in subsequent processes, which is beneficial for preparing low loss fibers.

| Advantage | ||||||

| High sedimentation rate; Easy to prepare large-sized prefabricated rods; Layer by layer deposition, easy to dope, suitable for preparing various types of optical fibers; Powder technology, easy to dehydrate and remove impurities, high purity of prefabricated rods, and easy to prepare low loss optical fibers |

||||||