Shanghai Gengyun Industrial Co., Ltd

Prefabricated rod

There are various types of gases required for fiber optic preform factories, which can be divided according to their different uses: providing power (compressed air), reaction gases (high-purity oxygen, hydrogen, chlorine), combustion and combustion support (ordinary hydrogen and ordinary oxygen), blowing and cleaning (nitrogen), process gases (argon and helium), etc. The main quality requirements of each gas should comply with the provisions of Table 2.3.2-1.

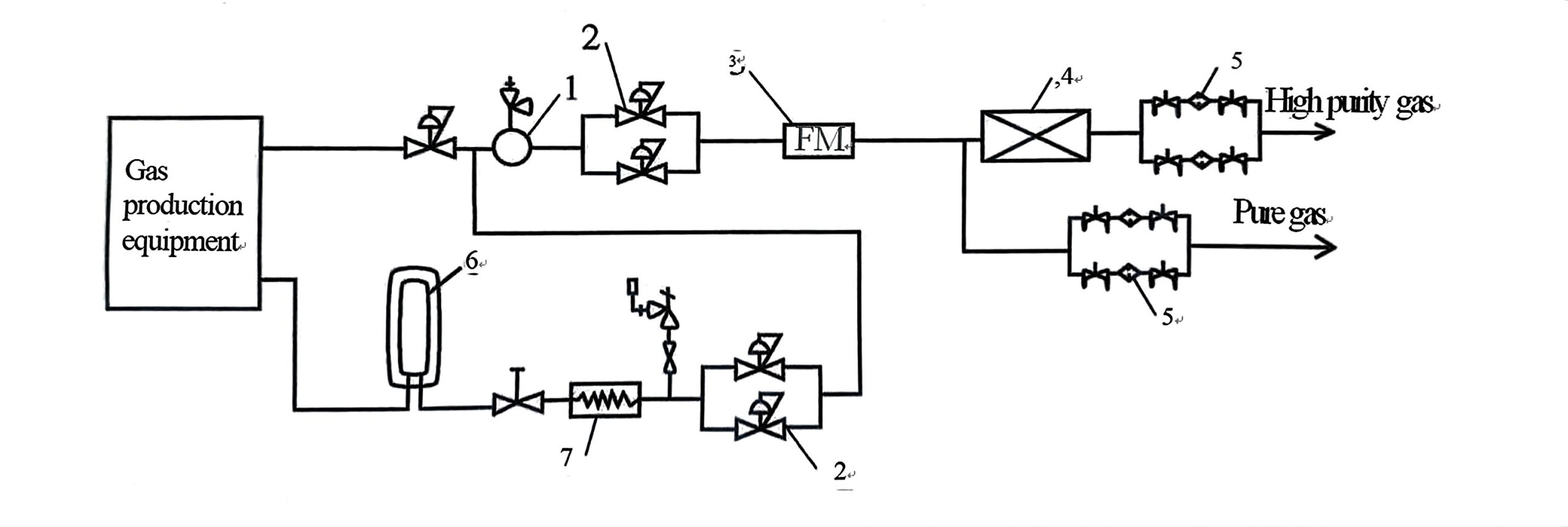

Among them, compressed air directly utilizes the atmosphere, and through the compressor, it outputs high-pressure air with stable pressure through cooling, drying, dust removal, oil discharge, and pressure reduction processes. The gas supply system for other ordinary gases or high-purity gases can be divided into three ways according to the different usage:

On site gas production, transported by pipelines to gas consumption points;

Purchase liquid gas externally and supply gas after gasification;

Purchase gas cylinders or containerized cylinder sets for gas supply after depressurization.

| For the selection of ordinary gas or high-purity gas supply methods, a specific industrial enterprise should be determined based on factors such as the scale of the factory, gas consumption and quality requirements, as well as the local or surrounding gas conditions, after careful technical and economic comparison. In addition, various rod making processes inevitably generate a large amount of waste gas containing gas, hydrogen chloride, etc., which cannot be directly discharged into the atmosphere. A waste gas environmental protection treatment system should be equipped. This section will introduce the various gas supply methods mentioned above, as well as accessories such as pipelines and joints. |

| Table 2.3.2-1 Main Quality Requirements for Each Gas | ||

| Name | Quality Requirements | Application |

| Compressed Air | Content ≤ 25mg/m Particles (>0.25 μ m)<20pes/sef Pressure 0.6MP Normal pressure setting point -20 ℃ |

Provide power |

| Nitrogen | Purity 4N Particles (≥ 0,25gm)<15pcs/sc Pressure 0.5MPa~0.6MPa |

Washing and drying protection |

| Hydrogen | Purity 4.5N Particles (>0.25 μ m)<15pes/scf Pressure 0.3MPa |

Maintain positive pressure or use ammonia as a protective gas |

| Nitrogen | Purity 4.5N Particles (>0.25 μ m)<15pes/scf Pressure 0.3MPa |

Enhance heat conduction and improve deposition efficiency |

| Ordinary Hydrogen Gas | Purity 3.5N Pressure 0.4MPa~0.6MPa |

Burning provides energy |

| Ordinary Oxygen | Purity 3.5N Pressure 0.4MPa~0.6MPa |

Boosting combustion |

| High Purity Nitrogen Gas | Purity 6N | Carrier gas |

| High Purity Hydrogen Gas | Bluntness 6N | Provide energy and react with carrier gas |

| High Purity Oxygen | Purity 6N | Participate in oxidation reaction and carry gas |

| Oxygen | Bluntness 5N | Dehydration drying |