Shanghai Gengyun Industrial Co., Ltd

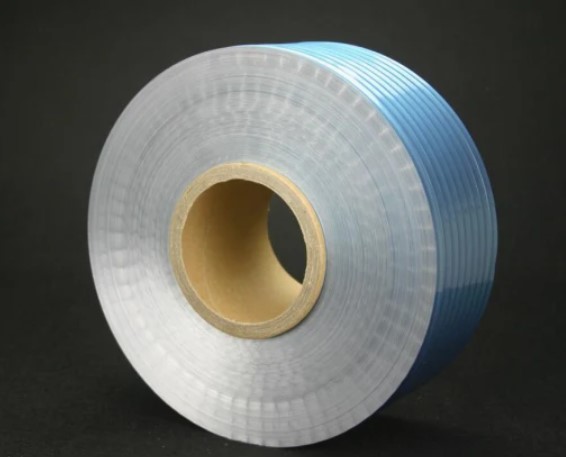

T-ST001 Copolymer Coated Aluminum Tape For Armoring Optical Fiber

TOEM armoring Shielding Insulation Copolymer Coated Steel Tape For Communication Optical Fiber Cable is ideal for wrapping and shielding communication optical fiber cables. It provides high temperature resistance, waterproofing, and armoring. Made with cold rolled steel, this flat tape is a reliable choice for your cable needs.

Single-sided or double-sided copolymer coated aluminum tape can be tightly bonded to the surface of aluminum and polyethylene covered cables. It is produced through three processes. First, copolymer film is generated by EAA and other chemical auxiliary additives in a certain ratio. Then the copolymer film and bare aluminum foil are loaded into the coating machine on one side/double sides. The loaded materials are bonded to each other through the pre-lamination process in the coating machine. At a certain temperature, the bare aluminum foil and copolymer film are completely bonded together through the coating line. Finally, the product is slit to obtain it.

Armoring Material Copolymer coated aluminum tape is most commonly used in the production of telephone and telecommunication cables to avoid interference and ensure the separation of internal cable groups.

Feature

- Good electrical conductivity;

- Copolymer Coated Aluminum Tape has good waterproofness;

- Good corrosion resistance;

- Good heat resistance;

Application

- shielding layer and waterproof layer of communication cable;

- shielding layer and waterproof layer of shielding cable;

- shielding layer and waterproof layer of waterproof cable;

- For roof and wall panels in construction;

Specification

| Inner diameter | Width | Outer diameter |

| 76mm/102mm/150mm/205mm//406mm | 12mm-1070mm | Up to 1200mm |

| Property | Unit | Typical Valug | Test Method | |

| Tensile strength | Mpa | ≥70 | ASTM E8 | |

| Elogation at break | % | ≥15 | ASTM E8 | |

| Peel strength | N/cm | ≥6.13 | ASTM B736 | |

| Heat seal strength | N/cm | ≥17.5 | ASTM B736 | |

| Filler/Floodant | No delaminat ion | REAPE-39,PE-89 | ||

| Water resistance 68±1ºC,168h peel strength | N/cm | ≥6.13 | ASTM B736 | |

| Dielectric strength two-side,DC1KV,1min | No Break | |||

| Corrosion resistance | Grade | 7 | ||