Shanghai Gengyun Industrial Co., Ltd

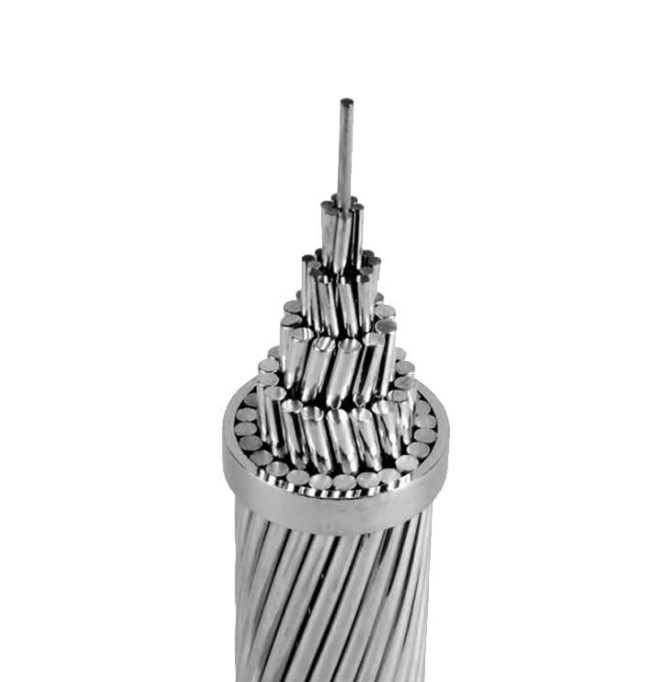

Wire for High Voltage Overhead Transmission Lines

Aluminum steel alloy wire is made of heat-treated aluminum magnesium silicon alloy material, divided into LHA1 and LHA2 levels, with conductivity equivalent to 52.5% IACS and 53.0% IACS, respectively, and has high strength and corrosion resistance.

The main parameters of aluminum alloy wire used in OPGW and OPPC |

|||||||

| Table 3.7.3-8 | |||||||

| Type | Nominal diameter mm |

Tensile strength (minimum value) MPa |

Density at 20℃ g/cm |

Resistance at 20 ℃ Rate (maximum value) nΩ ·m |

Resistance at 20 ℃ temperature coefficient 1/℃ |

Coefficient of linear expansion 1×10-*/℃ |

Elastic modulus GPa |

| IHA1 | d≤3.50 d>3.50 |

325 315 |

2.703 | 32.84 | 0.0036 | 23.0 | 65 |

| LHA2 | d≤3.50 d>3.50 |

295 295 |

2.703 | 32.53 | 0.0036 | 23.0 | 65 |

| Other Requirements: | |||||||

| 1.Outer diameter deviation (difference between aluminum alloy wire diameter and nominal diameter) When the diameter is less than or equal to 3.0mm, the deviation shall not exceed ± 0.03mm. When the diameter is above 3.0mm, the deviation shall not exceed ± 1%. 2.Elongation at break The minimum elongation at break of aluminum alloy wire is 3.0%, and the gauge length is 250mm. 3.Winding At a speed of no more than 60r/min, wind 8 turns on a core coil with the same diameter as the alloy wire, and the aluminum steel alloy wire should not break. |

|||||||