Shanghai Gengyun Industrial Co., Ltd

48 Core GYDTA Layer Stranded Ribbon Optical Cable

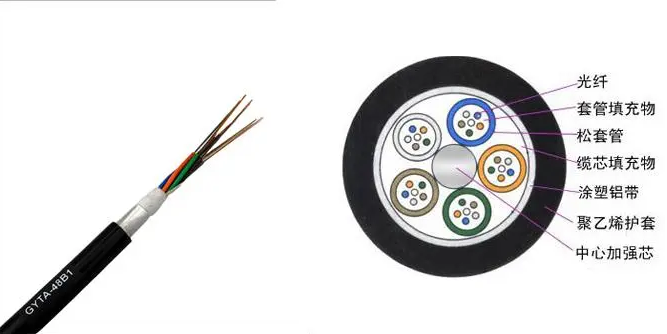

The structure of No.T-FC269 GYDTA Layer Stranded Ribbon Optical Cable is to wrap 4, 6, 8, and 12 core optical fiber strips into loose sleeves made of high modulus materials. TOEM Stranded loose tube optical cable fill the loose sleeves with waterproof compounds. The center of the outdoor fiber optic stranded cable core is a metal reinforced core, and for certain numbers of optical cables, a layer of polyethylene (PE) needs to be extruded outside the metal reinforced core. The loose sleeve and filling rope are twisted around the center to strengthen the core and form a compact and circular cable core. GYDTA Stranded Loose Tube Optical Cable Special tube filling compound ensure a critical protection of fiber. The gaps inside the cable core are filled with water blocking fillers. Plastic coated aluminum strip (APL) is longitudinally wrapped and extruded into a polyethylene sheath to form a cable. Manufacturing Multi-core Fiber

Application

- Fiber to the home:

- Fiber to the room;

- It is widely used in places with strict requirements on fire resistance, such as data centers, commercial buildings, public buildings, etc. This type of optical cable combines a layered twisted structure and flame retardant materials to improve the safety and reliability of the optical cable in a fire environment.

Feature

1. GYDTA layer stranded ribbon optical cable has excellent mechanical properties and temperature characteristics;

2.The loose tube material itself has good hydrolysis resistance and high strength;

3.The tube is filled with special ointment to provide critical protection for the optical fiber;

4.Specially designed compact fiber optic cable structure effectively prevents sleeve retraction;

5.PE sheath has excellent resistance to ultraviolet radiation;

6.Adopting 4, 6, 8, and 12 core fiber optic strips for flexible application;

7.Take the following measures to ensure the waterproof performance of the optical cable:

-Single steel wire center reinforcement core;

-Filling special waterproof compounds inside the loose tube;

-Complete cable core filling;

-Plastic coated aluminum strip (APL) moisture-proof layer;

Product Specification

| Fiber Type | Attenuation (+20ºC) |

Tape Width | NA | Cable Cutoff Wavelength | |||||||||

| @850nm | @1300nm | @1310nm | @1550nm | @850nm | @1300nm | ||||||||

| G.652 | — | — | ≤0.36dB/km | ≤0.22dB/km | — | — | ≤1260nm | ||||||

| G.655 | — | — | ≤0.40dB/km | ≤0.23dB/km | — | — | ≤1450nm | ||||||

| 50/125μm | ≤3.3dB/km | ≤1.2dB/km | — | — | ≥500MHzkm | ≥500MHz·km | 0.200±0.015 NA | — | |||||

| 62.5/125μm | ≤3.5dB/km | ≤1.2dB/km | — | — | ≥200MHzkm | ≥500MHzkm | 0.275±0.015NA | — | |||||