Shanghai Gengyun Industrial Co., Ltd

High Tensile 2-8 Core GYTA53+33 High Modulus Underwater Optical Cable/T-FC096

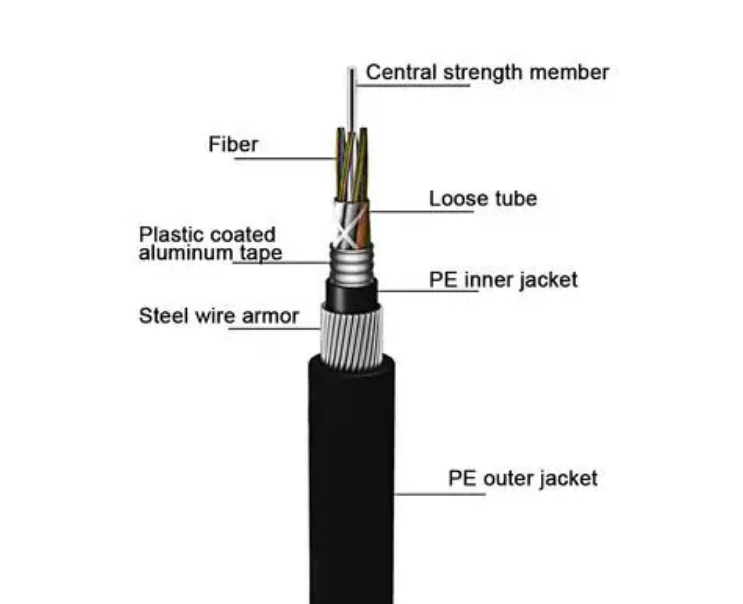

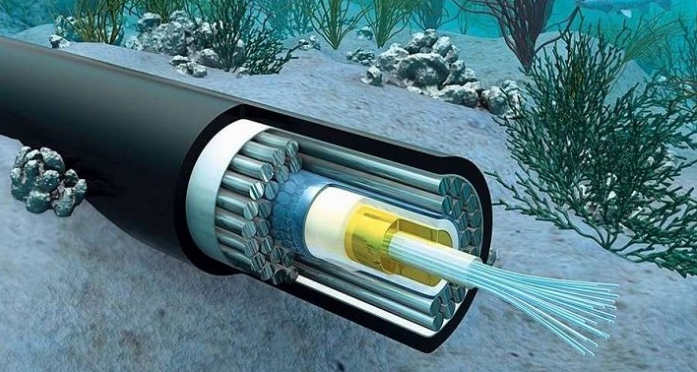

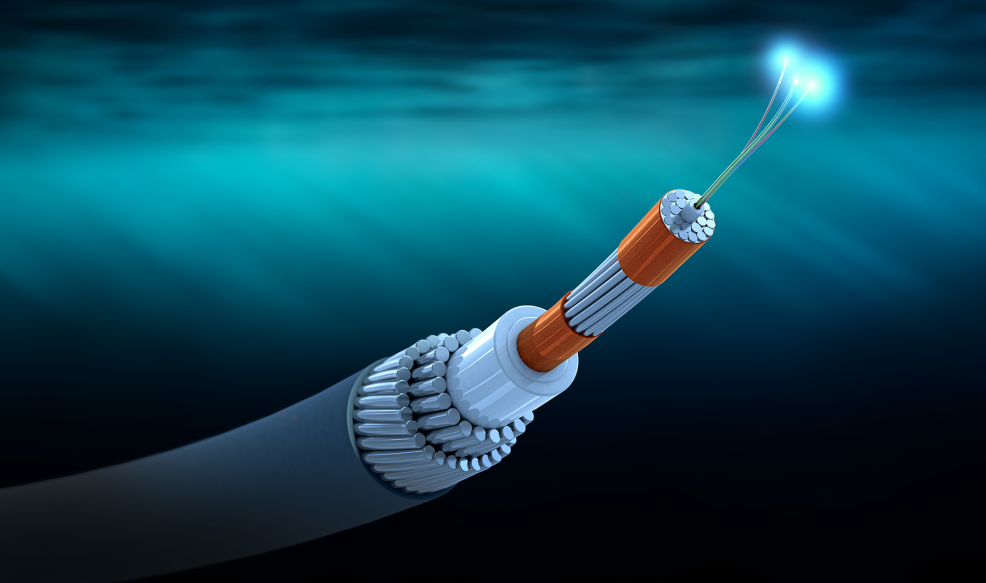

The high tensile underwater optical cable adopts a single steel wire central reinforcement core to enhance the tensile strength of the optical cable. After longitudinally wrapping with plastic-coated aluminum tape (APL), a polyethylene inner sheath is extruded to prevent longitudinal water seepage of the optical cable.

The structure of No.T-FC096 GYTA53+33 underwater optical cable is to insert 250 µ m optical fiber into a loose tube made of high modulus material, and fill the loose tube with waterproof compound. The center of the cable core is a metal reinforced core, and a loose sleeve (and filling rope) twisted around the center reinforced core to form a compact and circular cable core. The gaps inside the cable core filled with waterproof fillers. After being longitudinally wrapped with plastic coated aluminum strip (APL), a layer of polyethylene inner sheath is extruded, and after being longitudinally wrapped with double-sided plastic coated steel strip (PSP), a polyethylene outer sheath is extruded. After being armored with a single thin round steel wire, a polyethylene outer protective layer is finally extruded to form the cable.

Product Standard

Meet YD/T 901 and IEC 60794-1.

Product Feature

1. Single steel wire center reinforcement core;

2. Fill the loose tube with special waterproof compound;

3. Complete cable core filling;

4. Plastic coated aluminum strip (APL) moisture-proof layer;

5. Double sided coated steel strip (PSP) improves the moisture resistance of optical cables;

6. Good water blocking materials to prevent longitudinal water seepage in optical cables;

7. Underwater optical cable has excellent mechanical properties and temperature characteristics;

8. Single fine round steel wire armor enhances the tensile performance of optical cables;

9. The loose tube material itself has good hydrolysis resistance and high strength;

10.The tube filled with special ointment to provide critical protection for the optical fiber;

11.Good compression resistance and flexibility;

12.Ensure the waterproof performance of the optical cable;

Product Specification

| Cable Type | Fiber cores | Loose tube no. | Filler no. | Cable weight for reference (kg/km) |

Tensile strength(N) long-term/short-term |

Allow literal pressure long-term/short-term (N/100mm) |

Bending radius static/dynamic (mm) |

||||||

| GYTA53+33-2~6Xn | 2~6 | 1 | 5 | 801 | 4000/10000 | 3000/5000 | 12.5D/25D | ||||||

| GYTA53+33-8~12Xn | 8~12 | 2 | 4 | 801 | |||||||||

| GYTA53+33-14~18Xn | 14~18 | 3 | 3 | 801 | |||||||||

| GYTA53+33-20~24Xn | 20~24 | 4 | 2 | 801 | |||||||||

| GYTA53+33-26~30Xn | 26~30 | 5 | 1 | 801 | |||||||||

| GYTA53+33-32~36Xn | 32~36 | 6 | 0 | 801 | |||||||||

| GYTA53+33-2~6Xn | 2~6 | 1 | 5 | 984 | 10000/20000 | ||||||||

| GYTA53+33-8~12Xn | 8~12 | 2 | 4 | 984 | |||||||||

| GYTA53+33-14~18Xn | 14~18 | 3 | 3 | 984 | |||||||||

| GYTA53+33-20~24Xn | 20~24 | 4 | 2 | 984 | |||||||||

| GYTA53+33-26~30Xn | 26~30 | 5 | 1 | 984 | |||||||||

| GYTA53+33-32~36Xn | 32~36 | 6 | 0 | 984 | |||||||||

Storage,Working Temperature: -40ºC~+70ºC

| Fiber Type | Attenuation (+20ºC) |

Tape width | NA | Length | |||||||||

| @850nm | @1300nm | @1310nm | @1550nm | @850nm | 1300nm | ||||||||

| G.652 | — | — | ≤0.36dB/km | ≤0.22dB/km | — | — | — | ≤1260nm | |||||

| G.655 | — | — | ≤0.40dB/km | ≤0.23dB/km | — | — | — | ≤1450nm | |||||

| 50/125μm | ≤3.0dB/km | ≤1.0dB/km | — | — | ≥500MHz·km | ≥500MHz·km | 0.200±0.015 NA | — | |||||

| 62.5/125μm | ≤3.3dB/km | ≤1.0dB/km | — | — | ≥200 MHz·km | ≥500MHz·km | 0.275±0.015 NA | — | |||||

Product Standard

Standard disc tools;