Shanghai Gengyun Industrial Co., Ltd

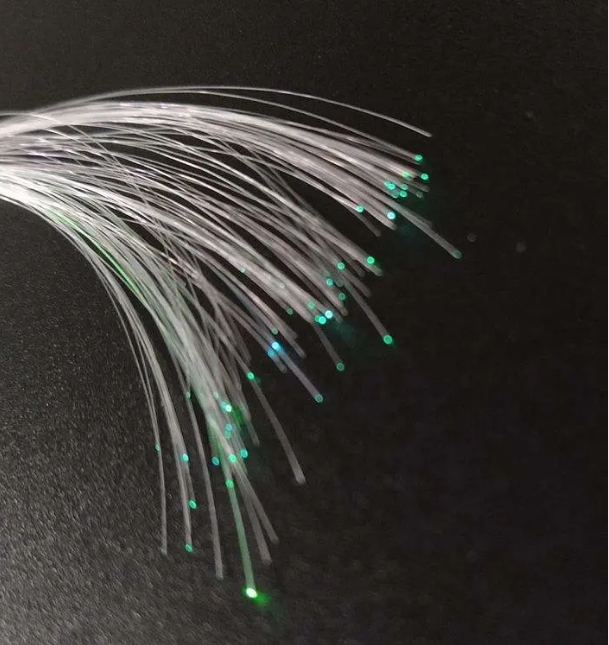

Optical Fiber Primary Coating Material Resin

Uv curable coating resin is a resin that can polymerize and solidify into a solid state.

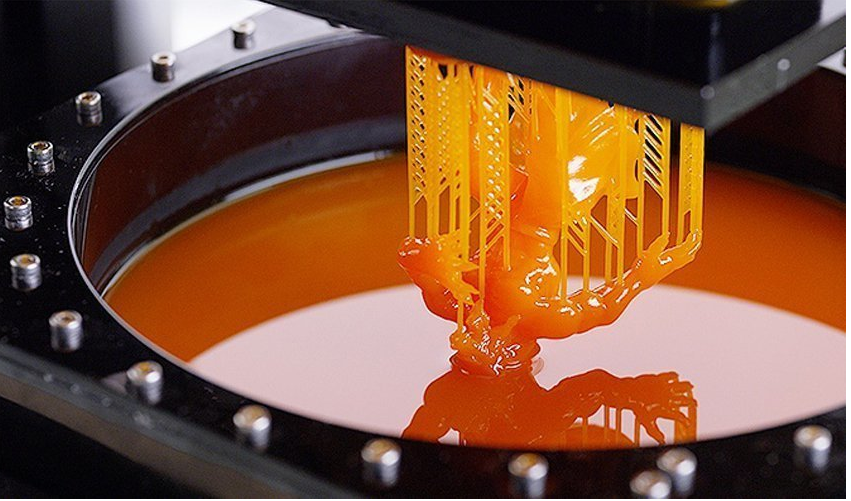

The curing principle of UV light curing resin (UV curing resin) is different from the thermal curing principle of other resins, which must be cured by UV machine / UVLED light curing machine. This process involves ultraviolet light irradiation, so that the terminal functional groups of some polymer materials in the resin have sufficient activity to react again under the irradiation of ultraviolet light, thus realizing crosslinking and curing. This curing technology takes advantage of the characteristics of the microscopic angle of polymer, that is, the terminal functional groups of some polymer materials have strong UV photosensitivity. Only under the irradiation of ultraviolet light, these functional groups can have enough activity to react again, manifested as curing.

No.T-RT1124 UV Curable Coating

Product Characters

| 1. Excellent process parameters, good for non-helium drawing process; | |||||||||||||||

| 2. Faster curing speed, UV-LED curable, energy efficient; | |||||||||||||||

| 3. Low volatile content, environmentally friendly; | |||||||||||||||

| 4. UV curable coating is suitable for wet-on-dry drawing processes; |

Product Specification |

||||||||||||||

| No. | Properties | Units | Standards | |||||||||||

| Before Curing (Liquid) | ||||||||||||||

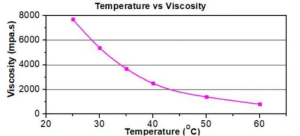

| 1 | Viscosity,25ºC | mPa.s | 7200-8000 | |||||||||||

| 2 | Density,20ºC | g/cm3 | 1.01-1.06 | |||||||||||

| 3 | Solid Content | % | >99 | |||||||||||

| 4 | Refractive Index,25ºC | 1.47±0.005 | ||||||||||||

| After Curing (Solid) | ||||||||||||||

| 5 | Glass Transition Temperature | ºC | ≤-30 | |||||||||||

| (DMA) | ||||||||||||||

| 6 | Secant Modules,2.5% | MPa | 1.0-1.4 | |||||||||||

| 7 | Elongation | % | 85-160 | |||||||||||

| 8 | Tensile Strength | MPa | 0.9-1.4 | |||||||||||

| 9 | Cure speed when RAU95% | J/cm2 | ≥1.2 | |||||||||||

| 10 | Oxygen generation(80ºC , 24h) | ul/g | ≤0.2 | |||||||||||

| 11 | Weight Change | 88ºC 8weeks | % | <-3.8 | ||||||||||

| 125ºC 8weeks | <-7.6 | |||||||||||||

| 12 | Adhesion | 50% RH | N | >0.45 | ||||||||||

| on glass | 95% RH | >0.35 | ||||||||||||

| * 75μ m film was made by curing under the nitrogen condition at UVA | ||||||||||||||

| 0.5J/cm2 with a Fusion D lamp,unless otherwise specified. UV | ||||||||||||||

| Dosemeter is by UV POWER PUCK II from EIT.INC.USA. | ||||||||||||||

Temperature – Viscosity Cure |