Shanghai Gengyun Industrial Co., Ltd

Retardant Virgin Recycled Poe/Po Polyolefin Cable Sheath Material

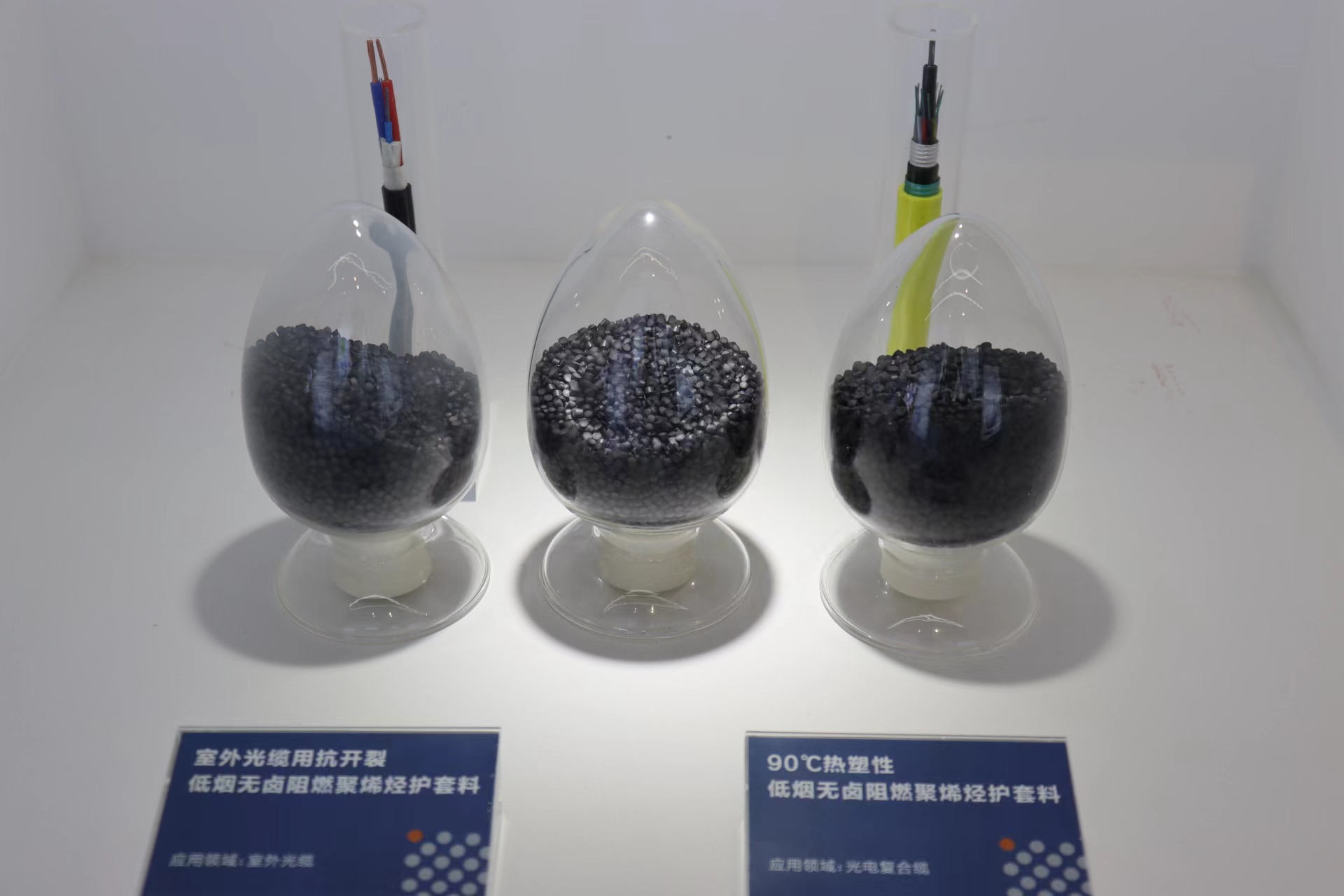

| T-PO006 Series – Low Smoke, Halogen-Free, Flame Retardant Polyolefin Cable Material Series Products For Indoor Optical Cables | |||||||||||||||

| Green Environmental, Low Shrinkage, Crack Resistance, Excellent Resistance To High And Low Temperatures. We Can Provide Various Products Such As Tight Packaging, Micro Bundle Tubes, Subunits, Outer Sheaths, Etc. The Flame Retardant Level Can Comply With Ec60332-1, Iec60332-3- (22, 23, 24), U1666 Ofnr, Cpr B2ca |

Environmental Friendly LSZH Low smoke zero halogen sheathing material do not contain halogens and do not produce toxic gases when burned. Thus reducing harm to the environment and human body. The amount of smoke produced by low smoke halogen-free sheathing materials during combustion is much lower than that of traditional cable sheathing materials such as PVC, which helps to improve visibility during fires and facilitates personnel evacuation and fire rescue. The low smoke zero halogen material complies with RoHS environmental protection standards.

Features

- Good flame retardancy;

- Low toxicity and low corrosion;

- lszh low smoke zero halogen material has heat and cold resistance;

- Excellent processing performance;

- Good mechanical properties. Such as tensile strength and elongation at break, can meet the use requirements of cables in different application scenarios.

Application

- LSZH low smoke zero halogen Cable sheath material is suitable for cable lines in transportation projects such as subways, high-speed railways, highways, bridges, etc;

- Widely used in communication systems such as telephones, computers, and networks;

- Environmental Friendly Low smoke halogen-free sheathing materials are also often used in cable lines in power systems. Such as power generation, transmission, substation, and distribution;

Specification

| Item | Unit | Test Method | Typical Value | |||||||||||||||||||||||||

| Density | g/cm3 | GB/T 1033.1 | 1.49 | |||||||||||||||||||||||||

| Tensile Strength | Mpa | GB/T1040.3-2006 | 12.7 | |||||||||||||||||||||||||

| Elongation At Break | % | GB/T 1040.3-2006 | 185 | |||||||||||||||||||||||||

| Low Temperature Impact Embrittlement Temperature (-40 ºC) | … | GB/T 5470-2008 | Pass | |||||||||||||||||||||||||

| Volume Resistivity (20 ºC) | Ω.m | GB/T 1410-2006 | 2.0×10¹ºC | |||||||||||||||||||||||||

| Smoke Density 25 Kw/m ² | Without Flames | GB/T8323.2-2008 | 220 | |||||||||||||||||||||||||

| With Flames | … | GB/T 8323.2-2008 | 41 | |||||||||||||||||||||||||

| Oxygen Index | % | GB/T 2406.2-2009 | 33 | |||||||||||||||||||||||||

| Thermal aging performance: | Tensile Strength | Mpa | GB/T 2951.12-2008 | 11.3 | ||||||||||||||||||||||||

| 100ºC*168h | Maximum Change Rate Of Tensile Strength | % | -11 | |||||||||||||||||||||||||

| Elongation At Break | % | 173 | ||||||||||||||||||||||||||

| Maximum Change Rate Of Elongation At Break | % | -6.5 | ||||||||||||||||||||||||||

| Thermal Deformation(90ºC,9.8N) | % | GB/T 8815-2008 | 11 | |||||||||||||||||||||||||

| Brinell Hardness HA | GB/T 2411 | 92 | ||||||||||||||||||||||||||

| Heat Resistant Stress Cracking | GB/T15065-2009 | Uncracked | ||||||||||||||||||||||||||

| Resistance To Environmental Stress Cracking | Fo/h | GB/T 2951,41-2008 | Pass | |||||||||||||||||||||||||

| Acidity Of Gas Released By Combustion | HCI & HBr | % | GB/T17650.1-1998 | 0 | ||||||||||||||||||||||||

| HF | % | IEC 60684-2:2003 | 0 | |||||||||||||||||||||||||

| PH | GB/T17650.2-1998 | 5.5 | ||||||||||||||||||||||||||

| Conductivity | μS/mm | GB/T 17650.2-1998 | 7.5 | |||||||||||||||||||||||||

| *Appearance: Uniform color and no impurities. Evaluation: Qualified, meeting the requirements specified by ROHS. | ||||||||||||||||||||||||||||

| Note: The above typical values are random sampling data. |

For more information about new products in the industry, please follow ofec.