Shanghai Gengyun Industrial Co., Ltd

What is TPU Elastomer?

TPU elastomer plastic is a melt-processable thermoplastic elastomer. It is a multifunctional elastomer with unique properties that provides first-class performance and processing flexibility. The full name of TPU is thermoplastic polyurethane, abbreviated as TPU. Thermoplastic Polyurethane (TPU) Material has the characteristics of both plastic and rubber. It is widely used in wires and cables, films, footwear. And clothing, automobile manufacturing, sporting goods, and industrial engineering.

Advantages of TPU Plastic Material

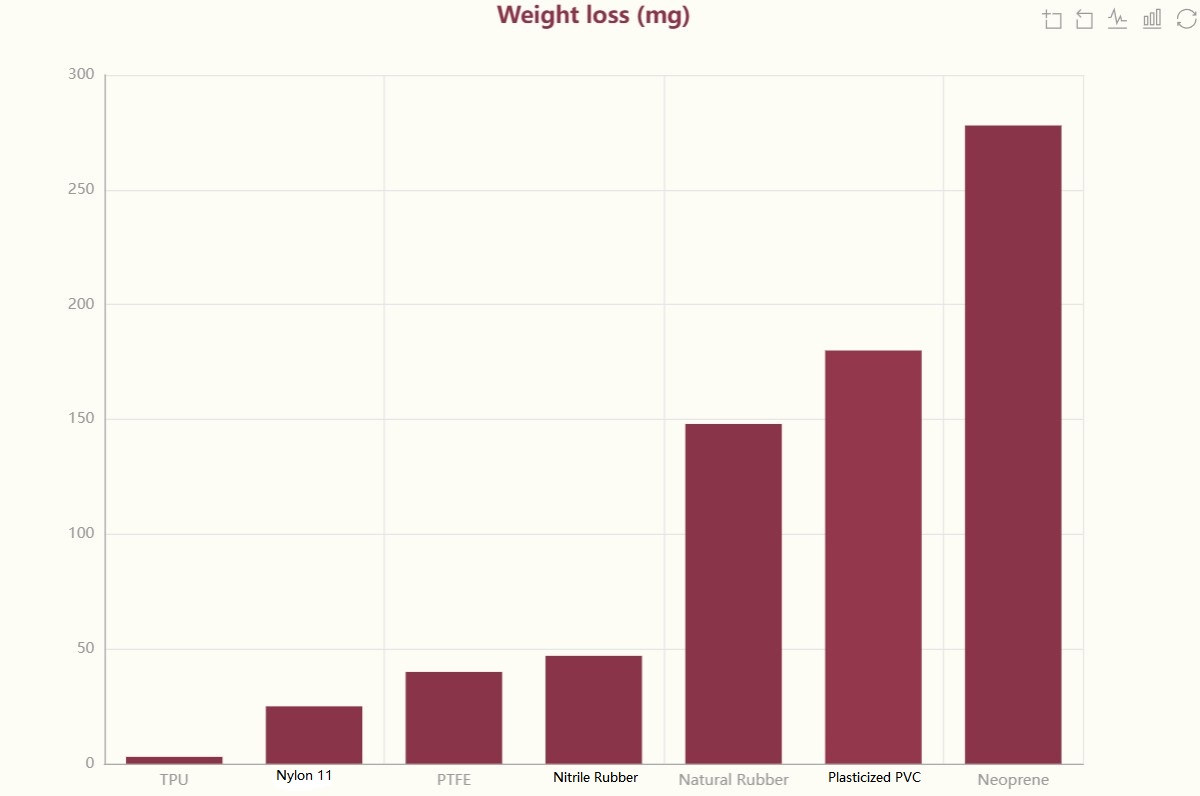

- Wear Resistance. TPU has good wear resistance, which makes it the preferred material for some applications. Such as materials for outdoor cable sheaths and special cables, etc.

- Good plasticity. TPU Elastomer can be processed using common thermoplastic material processing methods. Such as injection, extrusion, calendering, etc. They are very suitable for mass production.

- Environmental Protection. TPU is a green, environmentally friendly and renewable material. It can be degraded without pollution to the environment and harmless to the human body. TOEM’s TPU elastomer sheath material complies with ROHS certification.

- Weather Resistance and Cold resistance. Thermoplastic Polyurethane (TPU) Material has good high and low temperature resistance. It still maintains good elasticity and flexibility at minus 35 degrees. Therefore, it is very suitable as a material choice for pipeline wiring and direct buried wiring. At the same time, it has good mechanical strength. TPU products have outstanding bearing capacity, impact resistance and shock absorption performance. For example, TPU Elastomer optical cable sheath can well protect optical fiber cables and reduce the impact caused by environmental or human collision. Thereby extending the life of the optical cable.

- Excellent anti-aging and Anti-ultraviolet Performance.

- Certain Flame Retardancy.

- Oil Resistance.

Why is TPU Elastomer Plastic Material Suitable For Different Application Scenarios?

- Indoor Environment

In indoor environments, optical fiber cables usually need to withstand certain bending and extrusion. TPU sheath material can adapt well to these changes and protect optical fibers from damage due to its good flexibility and elasticity. At the same time, the excellent wear resistance of TPU Elastomer sheath material can resist various frictions in indoor environments. TPU plastic sheath material has excellent flame retardant properties. This enables it to protect optical fiber cables from damage in emergency situations such as fires.

- Outdoor Environment

In outdoor environment, Thermoplastic Polyurethane TPU sheath material has excellent weather resistance and low temperature resistance. It enables the optical fiber cable to withstand greater temperature changes, wind, sun and rain and other harsh conditions. This maintains the stability and performance of the cable.

- Direct Burial

In direct burial environment, Thermoplastic Polyurethane TPU sheath material can well protect the optical fiber cable from soil erosion and damage due to its good pressure resistance and corrosion resistance.

- Pipeline

In pipeline environment, TPU sheath material’s excellent wear resistance and oil resistance enable it to resist friction and oil erosion in the pipeline. Maintain the integrity and performance of the cable sheath.

- Overhead

In an overhead environment, fiber optic cables need to withstand the effects of wind and temperature changes. TPU plastic sheath materials can adapt well to these changes due to their excellent weather resistance and low temperature resistance. Maintain the stability and performance of the cable.

- Underwater

TPU’s excellent water resistance and corrosion resistance can resist various erosion and damage in underwater environments.

Summary

The TPU market is a growing industry, and its unique combination of properties has enabled it to replace traditional materials such as PVC and rubber in many fields. It is expected that the market for TPU elastomers will continue to expand in the next few years. If you don’t know how to choose TPU Elastomer materials, you can contact us. We will provide you with professional solutions.