Shanghai Gengyun Industrial Co., Ltd

What is a special aviation single core miniature cable

In the harsh environment of pursuing ultimate performance and safety in aircraft, special aviation single core micro cables have become an indispensable “nerve fiber” for modern aviation electronics, communication, and control systems due to their unique structural design. Its core advantages are reflected in

- Ultimate lightweight design to enhance flight efficiency:

Single core structure: Compared to multi-core cables, single core design significantly reduces the amount of internal insulation, fillers, and total sheath materials used.

Miniature size: Fine conductor diameter and optimized insulation/sheath thickness, significantly reducing weight per unit length.

Value proposition: In the aviation industry, weight is directly related to fuel consumption, payload, and flight range. Widely using this type of cable can significantly reduce the weight of the entire machine harness, improve the thrust to weight ratio, and increase economic benefits. - Micro flexible, adaptable to complex spaces:

Small outer diameter: can be easily laid in extremely narrow and winding passages such as aircraft fuselage, wings, engine compartments, etc.

High flexibility: easy to bend and wire, meeting the complex wiring requirements of modern aircraft high integration equipment layout, simplifying installation processes, and reducing space occupation. - Accurate signal transmission and strong anti-interference ability:

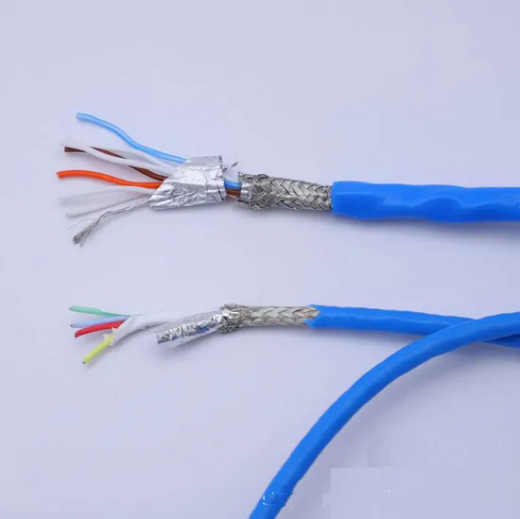

Independent shielding: Single core cables can usually easily achieve high-performance independent shielding (such as silver plated copper braided shielding, aluminum foil shielding, etc.), effectively isolating interference from complex electromagnetic environments onboard (engine ignition, radar, high-power equipment).

Excellent transmission characteristics: Optimized insulation materials and structural design ensure low loss, low latency, and high fidelity transmission of critical signals (such as sensor data, control commands, navigation information), enhancing system reliability. - Excellent environmental adaptability to ensure flight safety:

Special materials: using aviation grade high temperature resistant (-65 ° C to 200 ° C+), flame-retardant (low smoke and halogen-free), oil resistant, solvent resistant, moisture resistant, ozone resistant insulation and sheath materials (such as cross-linked polyolefin, ETFE, PTFE, etc.).

Durable and reliable: Excellent mechanical properties (wear resistance, vibration resistance, bending fatigue resistance) ensure long-term stable operation in harsh flight environments with high speed, high vibration, and temperature fluctuations, reducing the risk of failure. - Simplify maintenance and improve system reliability:

Clear structure: The single core structure is simple, easy to identify, detect, locate faults, and repair and replace.

High reliability: The combined effects of lightweight, anti-interference, and environmental resistance significantly extend the service life of cables, reduce maintenance frequency and costs, and improve aircraft attendance.

Summary of Special Aviation Single Core Micro Cable

Special aviation single core miniature cables are the intelligent crystallization of the aviation industry’s pursuit of high performance, high safety, and high efficiency. It is as light as a feather but as strong as a rock, accurately transmitting flight instructions between every inch, and not afraid of high-altitude cold, heat, and electromagnetic interference. It is an indispensable “precision neural network” for modern aircraft to efficiently and safely soar in the blue sky, providing a solid foundation for every successful flight.

For further guidance or to explore our range of high-quality fiber optic solutions. Visit TOEM and MIC TOEM, optical communications is our specialty.