Shanghai Gengyun Industrial Co., Ltd

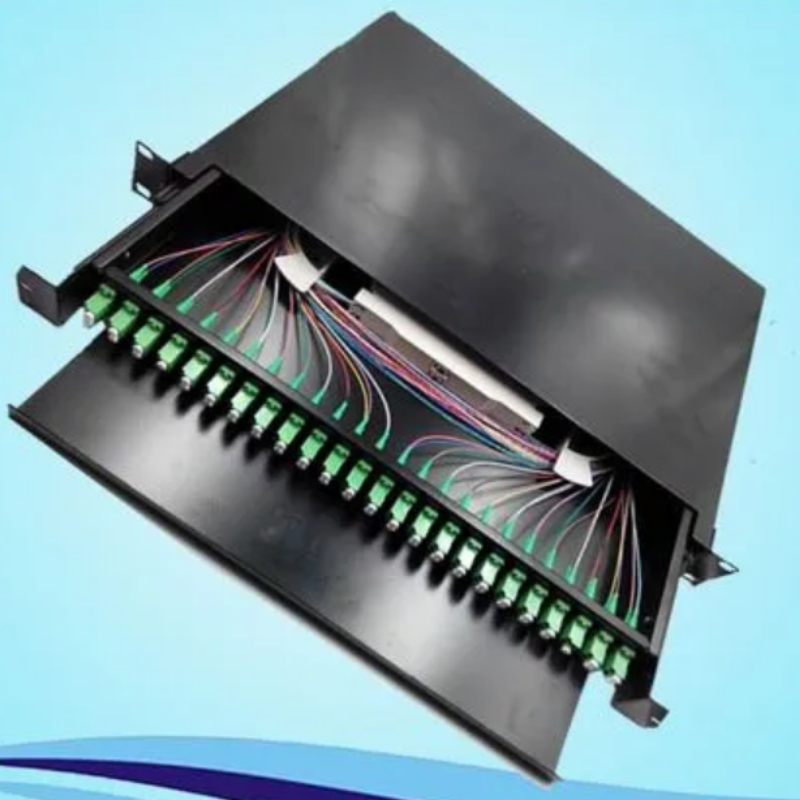

China Drawer Fiber Distribution Frame

Optical fiber welding for optical cable terminals, optical connector installation, optical path adjustment, storage of excess tail fiber and protective optical fiber distribution frame in one

Categories Data Center Products, Fiber Patch Panel

China Wholesale Fiber Distribution Frame

China Drawer Fiber Distribution Frame Features: |

| 1.Strictly follow the requirements of YY / T778-2011 Fiber-optic Distribution frame; |

| 2.Optical fiber distribution frame can be installed in the cabinet and wall installation, providing great flexibility for structured wiring design; |

| 3.The whole optical fiber travel protection design ensures the fiber bending radius> 40mm, and the fiber performance is not affected by cabling. While providing direct or cross connection for horizontal and trunk network; |

| 4.On the same optical fiber distribution frame can installed above 4 or more optical fiber adapters; |

| 5.Cframe module plastic buckle card connection structure. Which can pulled out from the front of the module. The pre-connected cable or optical fiber jumper can inserted, installation and maintenance quickly; |

| 6.With optical fiber fusion box, do not need to be configured separately. Which can melt up to 48 core. It can improve the use of the cabinet space full steel distribution frame frame structure. This ensure the higher mechanical performance of the product; |

| 7.Distribution frame shell with black fog flour powder coating treatment, clean and beautiful appearance; |

| 8.Coating materials and distribution frame frame all meet the requirements of environmental protection; |

| 9.The surface of the optical fiber panel also coated with powder to ensure the appearance of the matching and beautiful; |

| 10.The outer frame plate of the steel distribution frame is 1. [] 5mm thick, with high mechanical performance and strength, not easy to deform. And each surface of the shell can withstand the vertical static pressure of more than 250N; |

| 11The surface of the shell tested by salt spray test of GB / T2423. 17-1993 for 48h, and no visible rust spots were found on the surface. |

Standard |

||

| YD/T926.3, YD/T778-2011, TIA/EIA568 |

Specification |

|||

| Inserted numbers | N.W | Material | Sizes(MM) |

| 12 | 3.45KGS | SPCC cold rolled plate 1.2MM | 430*253*44 |

| 24 | 4.12KGS | SPCC cold rolled plate 1.2MM | 430*253*87 |

| 48 | 5.40KGS | SPCC cold rolled plate 1.2MM | 430*253*131 |

| 72 | 6.20KGS | SPCC cold rolled plate 1.2MM | 430*253*176 |

| 96 | 10.7KGS | SPCC cold rolled plate 1.2MM | 430*253*218 |

| 144 | 12.5KGS | SPCC cold rolled plate 1.2MM | 430*253*350 |

| PHYSICAL PARAMETERS |

| Operating temperature : |

| -10 °C~ 60 °C |

| storage temperature : |

| -40 °C~ 68 °C |

| Relative humidity: |

| 10% ~ 90% |