Shanghai Gengyun Industrial Co., Ltd

70 º C Environmental Friendly PVC Plastic Material Cable Wire Insulation Jacket Raw

Green Environmental PVC plastic has good dielectric properties and is widely used in the insulation layer of wires and cables, as well as in the manufacture of electrical equipment.

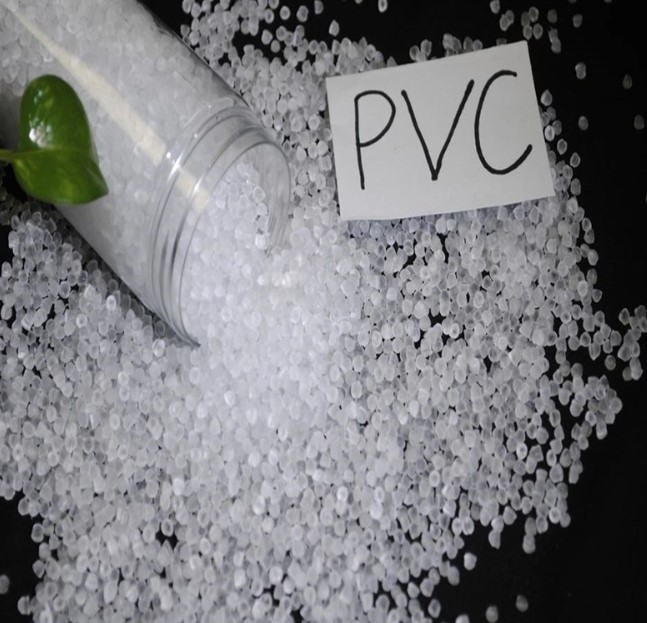

PVC environmental friendly product is a white powder with an amorphous structure, good mechanical properties. PVC plastic material has good dielectric properties and widely used in the insulation layer of wires and cables, as well as in the manufacture of electrical equipment.

Feature

- Good insulation;

- PVC plastic material has Weather resistance;

- Chemical corrosion resistance;

- Plasticity and flexibility;

Application

- Insulation and jacketing materials for fiber optic cables;

- Widely used in pvc pipes, window profiles, films, sheets, tubes, shoes, fittings;

- Package and Shipping;

Package and Storage

1.Packing:

25 kg/bag,50 kg/ bag or per your requirement.

18 mt/20’FCL,26 mt/40 FCL

2.Storage:

The resin should stored in a drafty, dry warehouse and away from fire and direct sunlight. It should not piled up in the open air.

3.Transportation:

During transportation, the product should not exposed to strong sunlight or rain and should not transported together with sand, soil, scrap metal, coal or glass. Transportation together with toxic, corrosive and flammable substance strictly prohibited.

PVC Plastic Material Basic Info

- Model NO: pvc;

- EINECS: 1.3-1.5;

- Material: Polyvinyl Chloride/PVC;

- Usage: General Plastics, Engineering Plastics, Specialty Plastics, Plastic Properties After Heated;

- Thermoplastic: Plastics;

- Plastic Forming Method: Film Pressure;

- Color: White/Black/Brown/Yellow;

- Length: as You Need;

- Conductor: Copper;

- MOQ: 5 kilometer/Kilometers;

- Sample Free: Yes;

- Specification: 1*1;

- HS Code: 390390;

- Production Capacity: 100000 Kg Per Day;

Technical Parameter

| Technical Analysis | |||||

| Physical Property | |||||

| No. | Inspection items | Standard request | Test method | Typical value | |

| Technical Index | |||||

| 1 | Density g/cm3 | / | GB 1033 | 1.45 | |

| 2 | Tensile strength MPa | ≥12.5 | GB 1040 | 13.8 | |

| 3 | Elongation at Break % | ≥200 | GB 1040 | 320 | |

| 4 | Hot deformation rate (90ºC×4h) % | ≤65 | GB8815 | 47 | |

| 5 | Brittle temperature | Failed No.≤15/30 | GB5470 | Pass | |

| Test temperature-25ºC | |||||

| 6 | 200 ºC static thermal stability min | ≥60 | GB8815 | 75 | |

| 7 | Volume Resistivity at 20ºC Ω .m | ≥1× 108 | GB/T 1410 | 2. 1 × 1010 | |

| 8 | Dielectric Strength MV/m | ≥18 | GB/T1408. 1 | 20 | |

| 9 | Thermal aging property | 100±2ºC , 168h | |||

| Tensile strength MPa | ≥12.5 | GB1040 | Pass | ||

| Max Variation on Tensile Strength % | ±20 | ||||

| Elongation at break % | ≥200 | ||||

| Max Variation on Elongation at break % | ±20 | ||||

| 10 | Thermal aging quality loss | ºC | 100±2 | GB/T2951 | |

| h | 168 | ||||

| Quality loss g/m2 | ≤25 | 18 | |||

| Quality of Appearance | |||||

| 1 | Appearance | Extruded lines | Eye survey | ||

| are smooth | |||||

| 2 | Color | Consistent color tone | Eye survey | ||

| Standard deviation ≤1.5 | Colorimeter | ||||

| *Note: | |||||

| 1 The extruded lines are smooth, and no more than 3 floating points with a diameter ≥1.0mm are allowed within 1 meter.No particles ≥ 3.0mm are allowed. | |||||

| 2 All products shall undergo initial inspection upon startup, including appearance, color, density, etc. | |||||

| 3 If the first sample test fails, a retest is required, and the result of the second test is the judgment standard. | |||||