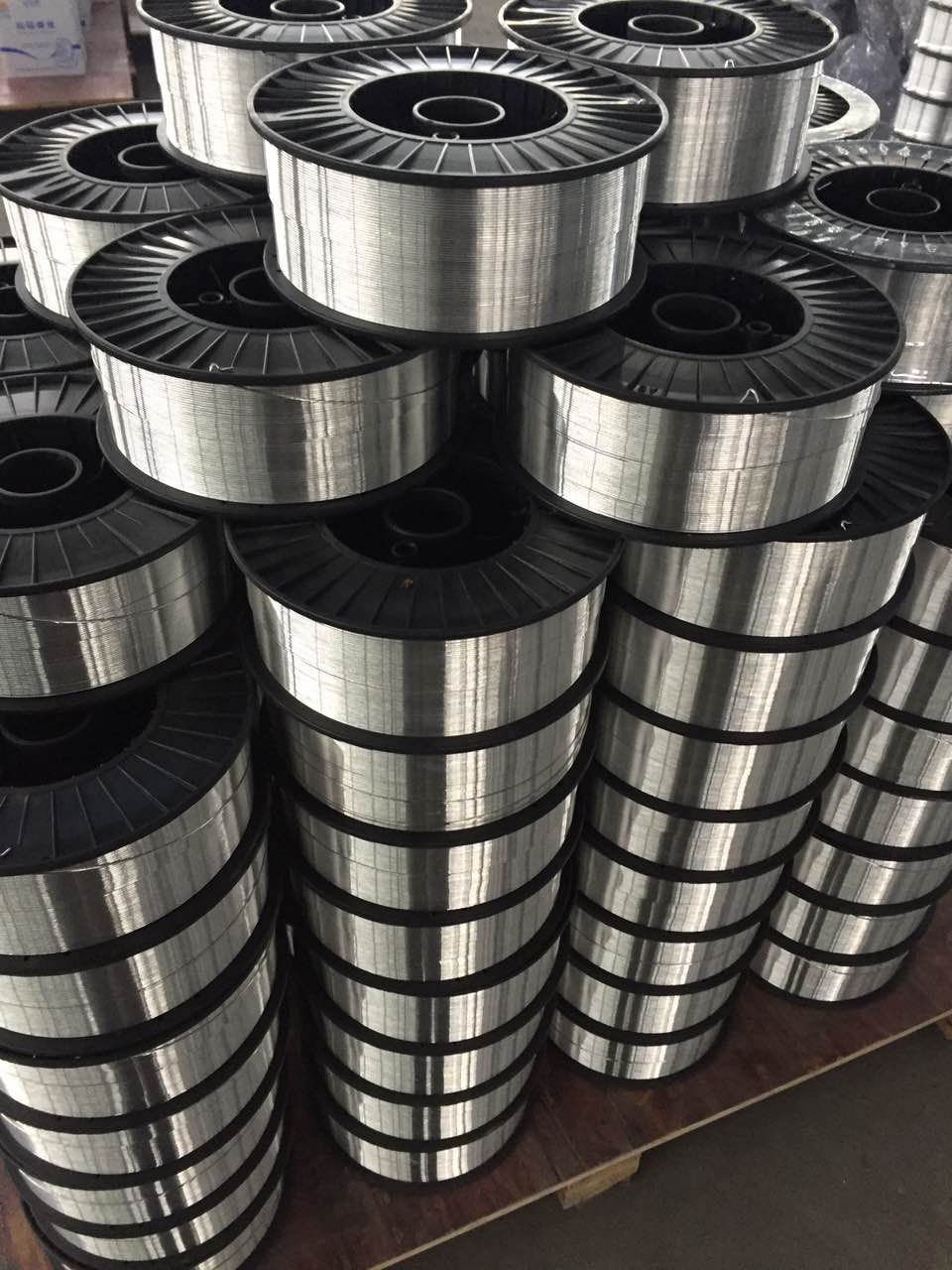

Shanghai Gengyun Industrial Co., Ltd

Aluminum Magnesium Alloy Coated Steel Wire

Alloy steel wire is a steel wire produced by drawing alloy steel wire rods. It has properties that are superior to carbon steel wire or that carbon steel wire does not have. By adding alloy elements ,wear resistance, fatigue resistance and toughness of the steel wire can be significantly improved.

| Table.7.3-2 Alloy Steel Wire size, allowable deviation, bundle weight | |||||||||

| Type | Nominal diameter(mm) | Allowable deviation(mm) | Bundle weight(kg) | ||||||

| RDZAM—2.0 | 2.0 | ±0.08 | ≥50 | ||||||

| RDZAM—3.0 | 3.0 | ±0.10 | ≥60 | ||||||

| RDZAM—4.0 | 4.0 | ±0.10 | ≥60 | ||||||

| RDZAM—6.0 | 6.0 | ±0.13 | ≥100 | ||||||

| RZZAM—2.0 | 2.0 | ±0.08 | ≥70 | ||||||

| RZZAM—3.0 | 3.0 | ±0.10 | ≥70 | ||||||

| RZZAM—4.0 | 4.0 | ±0.10 | ≥70 | ||||||

| RZZAM—5.0 | 5.0 | ±0.13 | ≥100 | ||||||

| Note: RDZAM represents low-carbon zinc aluminum magnesium alloy coated steel wire produced by hot dip coating method; RZZAM refers to medium carbon zinc aluminum magnesium alloy coated steel wire produced by hot dip coating method. | |||||||||

(2) Mechanical properties of steel wire |

|||||||||

| The requirements for the mechanical properties of alloy steel wire are shown in Table 3.7.3-3. | |||||||||

| Table 3.7.3-3 Mechanical properties of steel wire | |||||||||

| Type | Nominal diameter(mm) | Tensile strength N/mm ² | Elongation rate | Twist times/360° | |||||

| RDZAM—2.0 | 2.0 | 343~490 | ≥12% | ≥30 | |||||

| RDZAM—3.0 | 3.0 | ≥20 | |||||||

| RDZAM—4.0 | 4.0 | ≥15 | |||||||

| RDZAM—6.0 | 6.0 | ≥10 | |||||||

| RZZAM—2.0 | 2.0 | I Grade

1200 -1350 900 -1200 |

≥4% | ≥14 | |||||

| RZZAM—3.0 | 3.0 | ≥14 | |||||||

| RZZAM—4.0 | 4.0 | ≥14 | |||||||

| RZZAM—5.0 | 5.0 | ≥14 | |||||||

(3) Steel wire coating |

|||||||||

| The requirements for steel wire coating are shown in Table 3.7.3-4.

Table 3.7.3-4 Weight, thickness, and adhesion performance of steel wire coating |

|||||||||

| Type | Coating weight g/m ² | Coating thickness μm | Adhesion performance | ||||||

| The diameter of the core rod is a multiple of the diameter of the steel wire | Number of winding coils | ||||||||

| RDZAM—2.0 | ≥120 | ≥12 | 4 | ≥6 | |||||

| RDZAM—3.0 | ≥130 | ||||||||

| RDZAM—4.0 | ≥140 | 5 | |||||||

| RDZAM-6.0 | ≥140 | ||||||||

| RZZAM—2.0 | ≥100 | ≥8 | 5 | ≥6 | |||||

| RZZAM—3.0 | ≥100 | ||||||||

| RZZAM—4.0 | ≥110 | 6 | |||||||

| RZZAM—6.0 | ≥120 | ||||||||