Shanghai Gengyun Industrial Co., Ltd

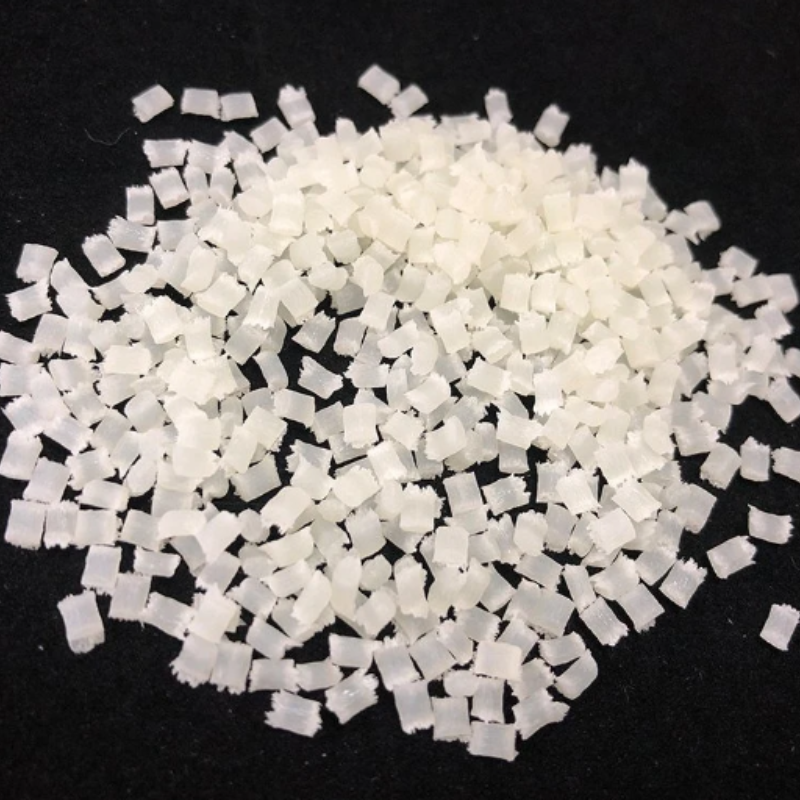

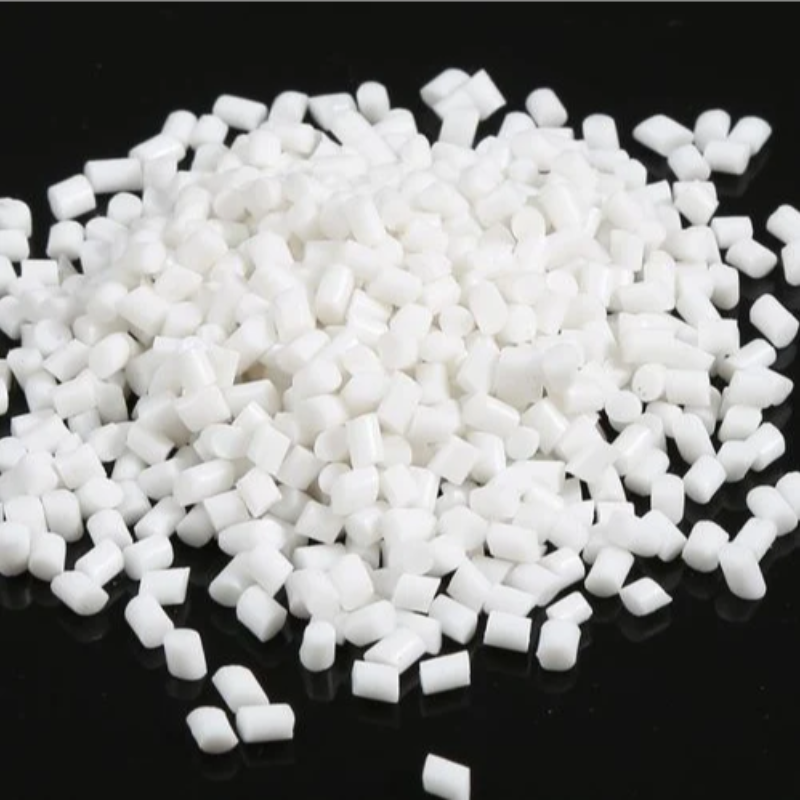

PVC Compound Polyvinyl Chloride Sheathing Granules

Based on pvc resin, Green Environmental plastic PVC material is a granular material made by mixing, plasticizing, and granulating with plasticizers, flame retardants, stabilizers, and cold resistant additives.

Categories PVC, Raw and Accessory Materials, Sheath Material

| Flame Retardant PVC Compound Type And Application | |||||

| PVC Plastic Material has good physical and mechanical properties, low-temperature performance. It has extrusion processing performance. And is suitable for wire. Flame retardant pvc compound also suitable for cable sheath materials with heat resistance temperature of 90 ºC. It meets requirements for cold resistance and flame retardancy. |

PVC Plastic Material Technology

| Performance | |||||

| Properties | Units | Detection | Typical Value | ||

| Method | |||||

| Density | g/cm3 | GB/T 1033.1 | 1.23 | ||

| Tensile strength | MPa | GB/T 1040.3 | 15.4 | ||

| Elongation at break | % | GB/T 1040.3 | 456 | ||

| After ageing in air oven | MPa | GB/T 8815 | 14.7 | ||

| 100±2ºC×240h | |||||

| Tensile strength | |||||

| Maximum variation for tensile strength | % | -5 | |||

| Elongation at break | % | 414 | |||

| Maximum variation for elongation at | % | -9 | |||

| break | |||||

| Mass loss | g/m2 | 36.6 | |||

| Hot deformation 121ºC×1h | % | GB/T 8815 | 58 | ||

| Stabilization time at 200ºC | min | GB/T 8815 | 105 | ||

| Low temperature brittleness test | ºC | GB/T 5470 | Pass | ||

| Oxygen index ( A ) | — | GB/T 2406.2 | 26 | ||

| Volume resistivity at 20ºC | Ω•m | GB/T 8815 | 2.1×1010 | ||

| Break down voltage | MV/m | GB/T 1408.1 | 22 | ||

| Plastic PVC Material Extrusion process | |||||

| The flame retardant pvc compound can be used with a regular PVC extruder. With a screw length to diameter ratio of L/D ≥ 20 Taking machine φ 90 as an example, pvc cable sheath material recommended to place two layers of filter screens with 40 mesh/80 mesh on the mesh plate. With the best extrusion surface being smooth and the cross-section having no pores. |

| The product refering to the extrusion processing temperature: | ||||||||||||

| Postion | Barrel Zone1 | Barrel Zone 2 | Barrel Zone 3 | Barrel Zone 4 | Head and Mold | |||||||

| Temperature(ºC) | 170±10 | 180±10 | 190±10 | 195±10 | 190±10 | |||||||

| *This process is based on our existing knowledge and experience, but due to the customer’s usage conditions not within our control, the above recommended process is only for reference. It recommended that users choose appropriate materials and production processes based on their extrusion equipment and cable structure. The above parameters are not applicable for quality control indicators. |