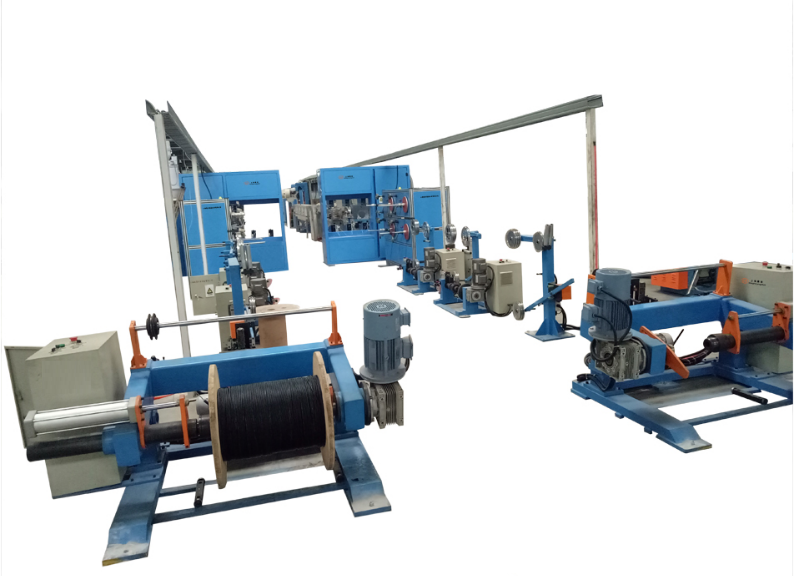

Shanghai Gengyun Industrial Co., Ltd

Fiber Optic Cable Sheath Production Equipment

The most commonly used types of protective layer structures for optical cables are polyethylene protective layer, aluminum polyethylene bonding protective layer, steel polyethylene bonding protective layer, and steel plastic bonding protective layer with steel wire. Special auxiliary equipment is required for special optical cables such as “8-shaped” optical cables, ADSS optical cables, and optical cable sheaths with special armor layers. The materials used for extruding the protective layer of optical cables include ILDPE, MDPE, HDPE, LSZH, TPU, nylon, etc.

Categories Manufacturing Equipment, Sheathing Line

| Application: 1)Inner sheath of optical cable: including polyethylene inner sheath, aluminum-plastic composite tape with polyethylene inner sheath. 2)Outer sheath of optical cable: including polyethylene outer sheath, aluminum-plastic composite tape with polyethylene integrated outer sheath, steel-plastic composite tape with polyethylene integrated outer sheath. 3)Extrusion materials for LDPE, MDPE, HDPE, etc. |

| Technical Specifications : | ||

| 1 | Cable core diameter | φ2.5~φ25mm |

| 2 | Extrusion sheath outer diameter | φ4.5~φ30mm±0.2 |

| 3 | Production speed | ≥80m/min(diameter is less than 12mm) |

| 4 | Line center height | 1000mm |

| 5 | Major machine extrusion volume | 260KG/H(PE) |

| 6 | Extruder main motor | 90kwZ4 DC motor |

| 7 | Electric power | 380V±10%,50HZ three-phase four-wire AC power supply |

| 8 | working environment | -5ºC~+40ºC,relative humidity:40%~90% |

| Production Line Composition: | ||

| 1 PN1600 ground rail gantry active pay-off rack | ||

| 2 Pay-off tension controller | ||

| 3 Rotary double-reel steel aluminum ribbon pay-off rack | ||

| 4 Steel(aluminum)with spot welding machine | ||

| 5 Steel (aluminum)belt storage device | ||

| 6 Steel (aluminum)with corrugated device | ||

| 7 Cable core jelly filling device | ||

| 8 Steel (aluminum)tape longitudinal wrap forming device | ||

| 9 φ90/25 extruder and feeding drying | ||

| 10 Cross head | ||

| 11 4m movable hot water trough and tank | ||

| 12 12m double-cooling water trough | ||

| 13 Blowing dryer | ||

| 14 Unidirectional diameter gauge(Shanghai EECTRL) | ||

| 15 Color ribbon printing meter | ||

| 16 800KG Crawler tractor | ||

| 17 PN1600 take-up and traversing rack | ||

| 18 Electronic control system |