Shanghai Gengyun Industrial Co., Ltd

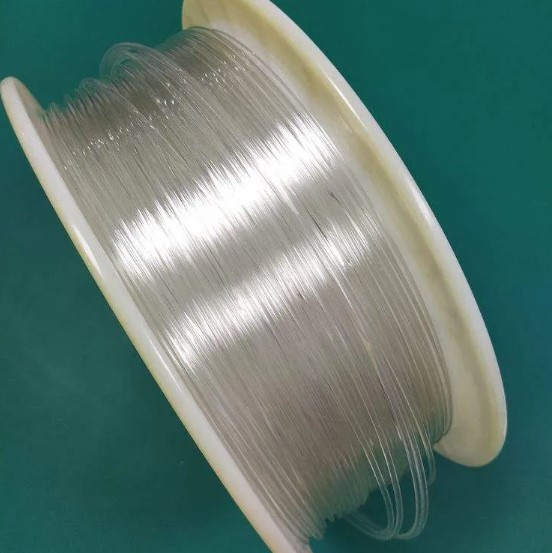

G.657.A1 Single Mode Fiber Optic

G.657.A1 fiber optic has high refractive index, Insensitive to bending, mainly used for Access network, fiber to the home, high-density wiring applications.

Categories G.657.A1, Optical Fiber, Products, Single Mode Fiber Optic

Product introduction

T-OF002-G.657.A1 , TOEM’s Bending Insensitive single-mode Optical Fiber , not only has outstanding bending insensitive characteristics. but also has excellent loss characteristics at 1310 nm and 1550 nm dual wavelengths, which is conducive to extending access network coverage.

Application Scenarios

FTTH Or FTTP

5G pre-network construction

Big data center & computer interconnection

Performance Features

Low loss & Bending Insensitive

Two optional diameters: 245 um (standard) & 200 um (optional)

Optimized MFD and precise geometric properties

Good compatibility with ordinary G.652.D

Technology Parameters

Optical

| Parameter | Conditions | Units | Value |

| Attenuation | 1310 nm | dB/km | ≤0.350 |

| 1383 nm | dB/km | ≤0.330 | |

| 1550 nm | dB/km | ≤0.210 | |

| 1625 nm | dB/km | ≤0.230 | |

| Attenuation vs.Wavelength | 1310 nm VS.1285-1330 nm | dB/km | ≤0.04 |

| 1550 nm VS.1525-1575 nm | dB/km | ≤0.03 | |

| Zero Dispersion Wavelength | nm | 1300-1324 | |

| Zero Dispersion Slope | ps/(nm2·km) | ≤0.092 | |

| Polarization Mode Dispersion (PMD) | |||

| Maximum Individual Fiber | ps/√km | 0.2 | |

| Link design value(M=20,Q=0.01%) | ps/√km | 0.1 | |

| Cut-off Wavelength 入cc. | nm | ≤1260 | |

| 1550 nm Mode Field Diameter(MFD) | 1310 nm | μm | 9.2±0.4 |

| 1550 nm | μm | 10.4±0.5 | |

| Attenuation Discontinuity | 1310 nm | dB | ≤0.03 |

| 1550 nm | dB | ≤0.03 |

Geometrical

| Parameter | Conditions | Units | Value |

| Cladding Diameter | μm | 125士0.7 | |

| Cladding Non-Circularity | % | ≤1.0 | |

| Core/Cladding Concentricity Error | μm | ≤0.5 | |

| Coating Diameter (Uncolored) | μm | 242士7(standard) | |

| 200±10 (optional) | |||

| Coating/Cladding Concentricity Error | μm | ≤12 | |

| Curl | m | ≥4 |

Environmental(1310 nm、1550 nm)

| Parameter | Conditions | Units | Value |

| Temperature Cycling | -60°C to +85°C | dB/km | ≤0.05 |

| High Temperature & High Humidity | 85°C at 85% RH | dB/km | ≤0.05 |

| Water Immersion | 23°C | dB/km | ≤0.05 |

| High Temperature Aging | 85℃ | dB/km | ≤0.05 |

Mechanical

| Parameter | Conditions | Units | Value |

| Proof Stress | % | 1.0 | |

| N | ≥9.1 | ||

| kpsi | 100 | ||

| Coating Strip Force | Peak | N | 1.3-8.9 |

| Average | N | 1.0-5.0 | |

| Tensile Strength | Fk=50% | GPa | ≥4.00 |

| Fk=15% | GPa | ≥3.20 | |

| Dynamic Fatigue (Nd) | ≥20 |

Macrobending Loss

| Parameter | Conditions | Units | Value |

| φ30 mm x10t | 1550 nm | dB | ≤0.25 |

| 1625 nm | dB | ≤1.0 | |

| φ20 mm xlt | 1550 nm | dB | ≤0.75 |

| 1625 nm | dB | ≤1.5 | |

| φ15 mm xlt | 1550 nm | dB | ≤0.4 |

| 1625 nm | dB | ≤0.8 |

Delivery Length

| Parameter | Conditions | Units | Value |

| Standard Reel Length | km | 2.1-50.4 |