Shanghai Gengyun Industrial Co., Ltd

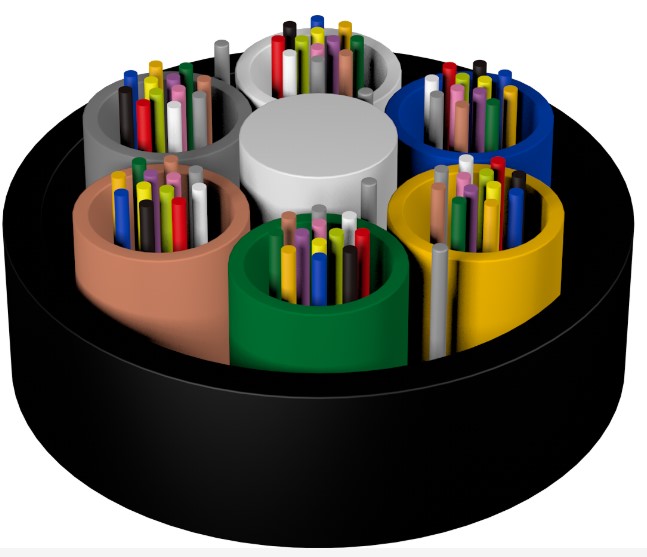

No.T-FC120 GCYFY loose tube stranded air blown cable adopts a non-metallic reinforcement and non-armored structure. It can laid by pulling or air-blowing the micro-duct in the laid outer protective tube. And then air-blowing the micro-cable in the micro-duct. It breaks through the limitations of existing pipeline cable laying technology. Which improves the utilization efficiency of the pipeline, and is easy to expand.

Product Applications

Used as a feeder segment to introduce optical cables in FTTH networks. Which using air blowing to connect the optical cable branch point and the user access point. It is also suitable for use in backbone networks, metropolitan area networks, and access networks.

Product Features

- Small diameter, light weight, moderate hardness and softness, easy to bend during air blowing laying, easy to operate;

- All non-metallic structure, no need for grounding, low friction coefficient sheath material and structural design, long air blowing distance;

- Make full use of pipe hole resources, fast construction speed of air blowing laying, long laying distance at one time;

- Air blown cable can be blown in batches as the communication business volume increases, investment is carried out in steps, and the initial investment is reduced;

- Micro cables can be blown out, which is convenient for replacing new types of optical fiber cables in the future, and maintaining technological leadership;

- Air blown cable is suitable for construction in crowded metropolitan area network pipelines, avoiding the previous destructive excavation;

- There is no need to decide in advance the location of the junction box and the optical cable divergence. Without affecting the normal operation of other optical cables, the outer protective tube and the micro tube in it can cut off at any time and anywhere to conduct optical cable divergence, while saving the number of manholes, hand holes and joints, and reducing the overall cost;

- Suitable for backbone networks, metropolitan area networks and access networks;

Delivery length

• Recommended length: 1/2/3KM; other lengths can be provided upon customer request;

Fiber Optic Spectrum

The spectrum can customized according to customer needs;

Specification of Air Blown Cable

| Product specifications | 12/24/36 | 24/48/72 | 96 | 144 | 192 | 216 | 288 | 144 | 192 | 288 | 432 | 576 |

| Number per die | 6 | 12 | 12 | 12 | 12 | 12 | 12 | 24 | 24 | 24 | 24 | 24 |

| Number of casings | 2/4/6 | 2/4/6 | 8 | 12 | 16 | 18 | 24 | 6 | 8 | 12 | 18 | 24 |

| Outer diameter of optical cable (mm) | 4.5 | 5.4 | 6.1 | 7.9 | 7.9 | 7.9 | 9.3 | 7.3 | 8.8 | 11.4 | 11.4 | 13.4 |

| Cable weight (Kg/km) | 16 | 26 | 36/29 | 52 | 52 | 52 | 80 | 42 | 76 | 110 | 105 | 140 |

| Maximum tension (N) | 200 | 600 | 800 | 800 | 600 | 600 | 1000 | 800 | 1000 | 1200 | 800 | 1200 |

| Allowable long-term/short-term tension (N) | 0.3G/1.0G | |||||||||||

| Allowable long-term/short-term flattening force (N/100mm) | 150/500 | |||||||||||

| Applicable microtube (mm) | 6/8 | 8/12 | 8/12 | 10/14 | 10/14 | 10/14 | 12/14 | 10/14 | 12/16 | 14/16 | 14/16 | 16/20 |

| Typical blowing distance (m) | ≥1200 | |||||||||||

| Transport/storage/use temperature | -40℃ ~ +70℃ | |||||||||||

| Installation temperature | -5℃ ~ +50℃ | |||||||||||

Note: G represents the weight of 1 Km optical cable.