Shanghai Gengyun Industrial Co., Ltd

Optical Drive Power Composite Cable T-FC115v

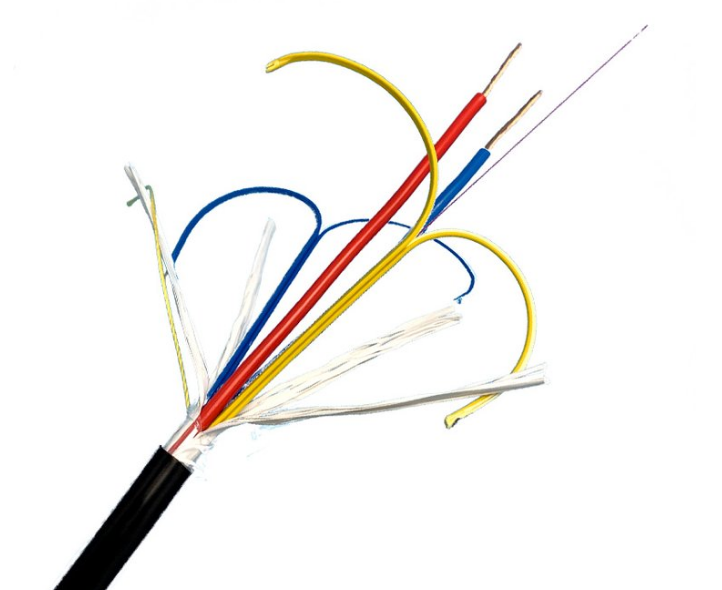

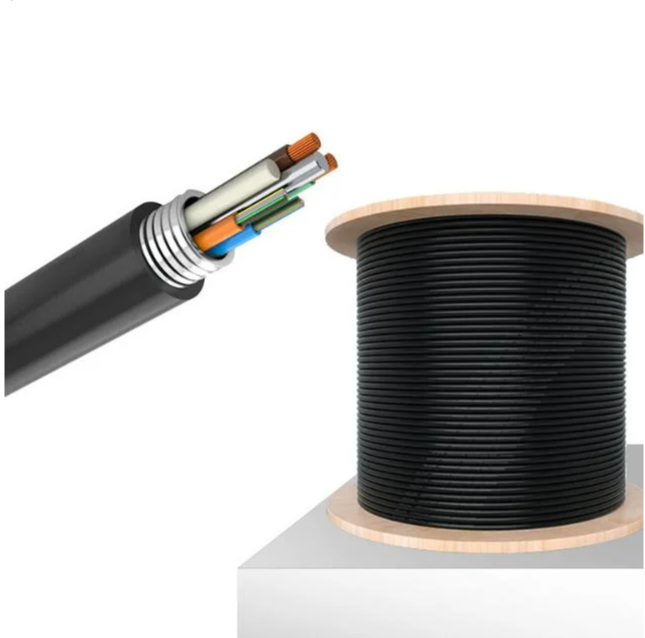

Optical power composite cable has good waterproof performance. The center of the cable core is a metal reinforcement core to enhance the tensile strength of the optical cable. The precise control of the excess length of the optical power composite cable ensures that the optical cable has good tensile performance and temperature characteristics. Optical drive power cable is mainly used for remote base station wiring, pipeline wiring and overhead laying.

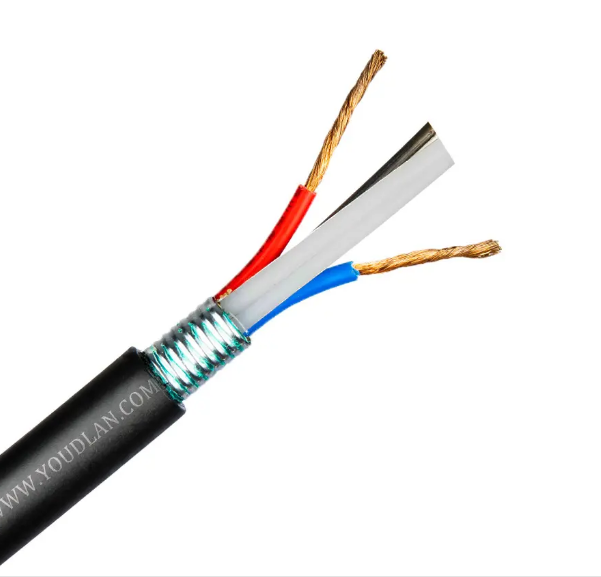

No.T-PC014 Optical power composite cable has good waterproof performance. It puts single-mode or multi-mode optical fiber into a loose tube made of high modulus polyester material, and the tube is filled with waterproof compound. The center of the optical drive power cable core is a metal reinforcement core to enhance the tensile strength of the optical cable. For a certain number of optical cables, a layer of polyethylene needs to be extruded outside the metal reinforcement core. It is used to reduce the wear of the optical cable caused by collision or transportation.

The precise control of the excess length of the optical power composite cable ensures that the optical cable has good tensile performance and temperature characteristics. The optical cable is made of double-sided chrome-plated plastic-coated steel tape (PSP) longitudinally rolled and then extruded with a polyethylene sheath to form a cable. This improves wear resistance and extends the service life of the optical cable. Optical drive power cable is mainly used for remote base station wiring, pipeline wiring and overhead laying.

Feature

- Good lateral pressure resistance

- Good bending;

- Light weight, small outer diameter, easy deployment;

- Good tensile performance and temperature characteristics;

- Improve power supply manageability, reduce power supply coordination and maintenance;

- Optoelectronic integration, solve equipment power supply and signal transmission problems. Provide centralized monitoring and maintenance of equipment power supply;

Application

- Mainly used for pipeline laying;

- Mainly used for overhead laying;

- Remote base station wiring;

Specification

| Construction and Specification: | ||||||||||

| Model No. | Specification | Weight(Kg/km) | Tensile Strength | Crush Resistance | Structure | |||||

| Long/short term | Long/short term | |||||||||

| (N) | (N/100mm) | |||||||||

| T-PC013 | GDTS-02~24Xn+2×1.5 | 157 | 600/1500 | 300/1000 | I | |||||

| T-PC014 | GDTS-02~24Xn+2×2.5 | 190 | 600/1500 | 300/1000 | II | |||||

| T-PC015 | GDTS-02~24Xn+2×4.0 | 241 | 600/1500 | 300/1000 | II | |||||

| T-PC016 | GDTS-02~24Xn+2×5.0 | 282 | 600/1500 | 300/1000 | III | |||||

| T-PC017 | GDTS-02~24Xn+2×6.0 | 300 | 600/1500 | 300/1000 | III | |||||

| T-PC018 | GDTS-02~24Xn+2×8.0 | 383 | 600/150 | 300/1000 | III | |||||

| *Note: Xn represents fiber type 2 × 1.5/2 × 2.5/2 × 4.0/2 × 6.0/2 × 8.0, indicating the number and specification of wires | ||||||||||

| We can produce optoelectronic hybrid cables with different wire specifications and quantities according to your requirements | ||||||||||

| We can produce optoelectronic composite cables with different numbers of fiber cores according to your requirements | ||||||||||

| Electrical Performance of Insulating Conductor: | |||||||||

| conductor cross-section | Maximum DC resistance of a single conductor | Insulation resistance | Dielectric strength KV,DC 1minute | ||||||

| (mm) | (20ºC)(Ω/km) | 20 ºC (MΩ.km) | |||||||

| Between each insulated wire and other metals connected inside the cable | Between wires | Wire and metal armored tape | Between wire and steel wire | ||||||

| 1.5 | 13.3 | ≥10000 | 5 | 5 | 3 | ||||

| 2.5 | 7.98 | ||||||||

| 4 | 4.95 | ||||||||

| 5 | 3.88 | ||||||||

| 6 | 3.3 | ||||||||

| 8 | 2.47 | ||||||||

| *Note: The relevant performance of the feeder conductor meets GB/T3956-2008, and the electrical performance of the feeder meets GB/T5023.3-2007 | |||||||||

Transportion /Storage/Operating Temperature: -40ºC~+70ºC

| Packaging: |

| Export Standard |