Shanghai Gengyun Industrial Co., Ltd

High Power Output Ring Optical Fiber Specialty Fiber for Laser Welding

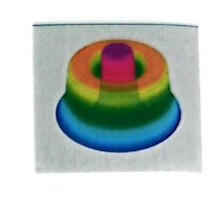

TOEM introduces No.T-OF32161119A ring optical fiber to meet the high power output requirements of ring structure laser and Kwangtung mode tunable laser.Different from the single-peak Gaussian distribution of the traditional laser power.

It is shaped by the ring fiber.A Gaussian distribution lase beam forming that core and a circular lase beam surrounding it are used in parallel.And can effectively reduce that fly phenomenon of high-power lase welding.

Product Characters

1. Ring optical fiber has good ring concentricity;

2. That output of the core area and the re area is independently adjustable;

3. All-fiber solutions to improve system reliability;

4. Acceptable customized waveguide structure;

Product Application

1. Ring Optical Fiber is suitable for High power laser;

2. Welding processing of new energy batteries, automotive parts and electronic components;

3. Ring fiber optic is suitable for localization substitution of imported products;

Product Specification

Product indicator 1

| Fiber type | GOF_KC GOF_MC GOF_MC GOOEK GOF_KC 14200 14/4804.07 20/200-0.065 25/2004.11 14/100/120/200 0.07 |

||||

| Product number | 061119-A | 001119-8 | DO1115E | DG1119< | DG1113-0 |

| Optical properties | |||||

| Working section length (mm) | 800-1600 | ||||

| Core numerical aperture | 0.07±0.005 | 0.07±0.005 | 0.07±0.005 | 0.005±0.005 | 0.110±0.005 |

| First cladding numerical aperture | φ22±0.02 | 0.22±0.02 | 022±0.02 | 0.22±0.02 | 0.22±0.02 |

| Third cladding numerical aperture | 022±0.02 | 022±0.02 | 0.22±0.02 | 022±0.02 | |

| Packing material value aperture | ≥0.45 | 20.46 | 2046 | ≥0.46 | 2046 |

| Geometrical properties | |||||

| Thought Live Broadcast (1) | 14.0±2 | 145±15 | 14.5±20 | 20.0±20 | 25.0±2.0 |

| Diameter of the first whole layer (mm) | 100.0±4.0 | 34.0±3.0 | 34.0±3.0 | 40.0±4.0 | 35.0±3.0 |

| Diameter of the second wheel layer (mm) | 120.0±4.0 | 48.0±5.0 | 50.0±4.0 | 54.0±5.0 | 50.0±3.0 |

| Third mixing diameter (mm) | 2000±40 | 102.0±5.0 | 400.0±5.0 | 1200±50 | 2000140 |

| Diameter of the fourth bit layer (μm) | 125.0±5.0 | 455.0±8.0 | 150.0±50 | 120.0±4.0 | |

| Diameter of the fifth layer () | 200.0±5.0 | 480.0±10.0 | 200.0±5.0 | 200.0±4.0 | |

| Concentration diameter (mm) | 320.0±15.0 | 300.0±15.0 | 600.0±20.0 | 300.0±15.0 | 330.0±15.0 |

| Material properties Reduction tension (kg) Inner coating material |

≥100 Low refractive index coating |

≥100 Low freshness coating |

≥100 Crystallization with low new production rate |

2100 Low fresh rate coating |

≥100 Low fold material * * 2 |

| Overcoat material | Acrylic resin | Acrylic resin | Acrylic acid dilute ester sodium acrylate | ||

Product indicator 2

| Number of light books | 5134/50 95000 5150/50 95070 … |

|||||

| Product number | 521174 | 501114 | 92117 | 921174 | 921174 | |

| Gender after school | ||||||

| Working length (nm) | 100-1000 | |||||

| Mark the number of holes and columns | 0221000 | 0221000 | 0222482 | 0221000 | 0221002 | |

| The second round is numerical aperture. | 02210:02 | 0221000 | 022100 | 022100 | 0222002 | |

| “I” | 2044 | 2046 | 2046 | 2046 | 2046 | |

| Geometric gender | ||||||

| 340+20 | 340120 | 340120 | 500±20 | 500120 | ||

| First package diameter | 480±40 | 500±48 | 700140 | 800250 | 710240 | |

| Second package diameter (m) | 1020±50 | 4000±10 | 150.0±5.0 | 2000110 | 2000180 | |

| Third Cladding Diameter (m) | 1200130 | 4000240 | 1700210 | 2000110 | 3000180 | |

| Huangchang packaging diameter (I) | 200158 | 40002100 | 2000250 | 2000175 | 460.2246 | |

| () | 650.0±20.0 | 00001200 | 560.0±20.0 | 540.0±25.0 | 40001200 | |

| Gender of material | ||||||

| 2100 | 2100 | 2100 | ≥100 | 2100 | ||

| Inner coating material | Low refractive index coating | Low refractive index coating | Low discount rate sub-volume | Mission materials * * | Low frequency type | |

| Outer coating material | Acrylic resin | Number of internal fittings | Zhou Tingying and Shu Tao | Acrylic manufacturing | Acrylic acid time | |

Product indicator 3

| Fiber type | 5150mg 51100/130 51109/130 -22/400/440 22/000/00 22100000 2200000 -22/500(750 22/400/120 -22/460/450 -22/750/150 |

|||

| Product number | 50117-J | 502174 | 5121174 | 501170 |

| Optical properties Working Committee Chairman () |

||||

| Cellulosic number and pore size | 0.22±5.02 | 800-1500 0.22±0.02 |

0.22±0.02 | 0.22±0.02 |

| Cond population numerical aperture | 0.22±0.02 | 0.22±0.02 | 022±000 | 0.22±0.02 |

| Packing quantity without warp | 20246 | 2046 | 2046 | 2046 |

| Geometrical properties Core engraving diameter (mm) |

50.0±20 | 50.0±30 | 100.0±20 | 100.0±5.0 |

| First layer diameter (mm) | 700±50 | 700±40 | 1304±4.0 | 130.0±8.0 |

| 2nd package diameter (cm) Third Cladding Diameter (mm) |

400.0±8.0 440.0±8.0 |

600.0±80 630.0±8.0 |

2000250 2002:50 |

600.0±10.0 670.0±15.0 |

| Fourth Cladding Diameter (mm) | 550.0±8.0 | 6020±100 | 400.0150 | 750.0±20.0 |

| Paint layer diameter (μm) | 750.0±25.0 | 8200±40.0 | 650.0±20.0 | 9500±250 |

| Material properties >120 |

>100 | ≥100 | 285 Low-low rate refrigerator |

|

| Screening vibration force (KPS) Inner ice material Bone coating material |

Low refractive index coating Inline loading ( |

The low new production rate is blackened Acrylic acid |

Low refractive index coating | Acrylic ester grease |