Shanghai Gengyun Industrial Co., Ltd

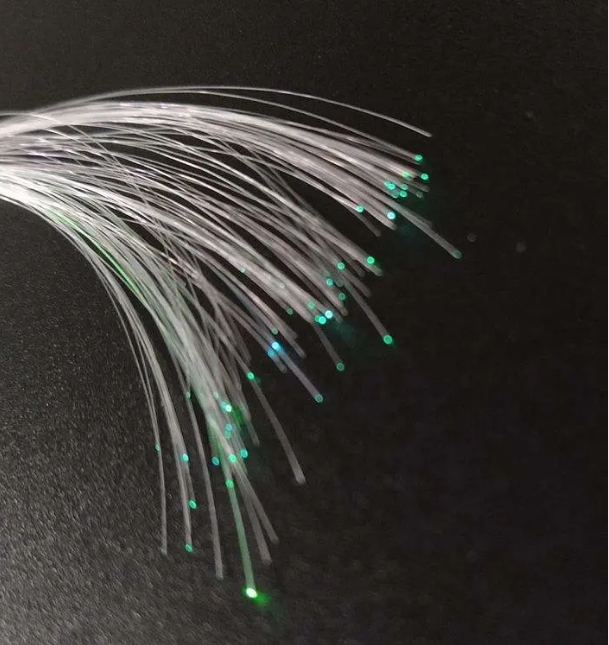

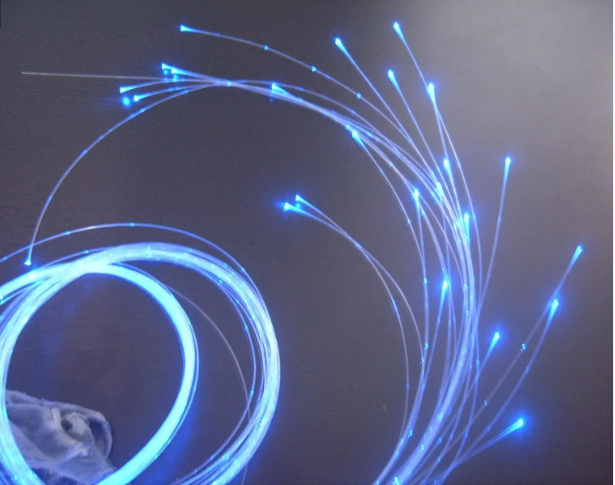

LED Curable Secondary Coating Resin for Optical Fiber/ T-RT2124

T-RT2124 is a high viscosity, designed for UV-LED high speed drawing optical fiber secondary coating.

| Product Specification | ||||||||||||||

| No. | Properties | Units | Standards | |||||||||||

| Before Curing (Liquid) | ||||||||||||||

| 1 | Viscosity,25ºC | mPa.s | 5800-6600 | |||||||||||

| 2 | Density,20ºC | g/cm3 | 1.11-1.12 | |||||||||||

| 3 | Solid Content | % | >99 | |||||||||||

| 4 | Refractive Index,25ºC | 1.51±0.005 | ||||||||||||

| After Curing (Solid) | ||||||||||||||

| 5 | Glass Transition Temperature | ºC | ≥50 | |||||||||||

| (DMA) | ||||||||||||||

| 6 | Secant Modules,2.5% | MPa | 900-1100 | |||||||||||

| 7 | Elongation | % | 12月28日 | |||||||||||

| 8 | Tensile Strength | MPa | 35-45 | |||||||||||

| 9 | Cure speed when RAU95% | J/cm2 | ≥1.2 | |||||||||||

| 10 | Oxygen generation(80ºC , 24h) | ul/g | ≤0.2 | |||||||||||

| 11 | Weight Change | 88ºC 8weeks | % | <-1.0 | ||||||||||

| 125ºC 8weeks | <-4.6 | |||||||||||||

| 12 | (15g/m2 on PE ) | >0.20 | ||||||||||||

| Coefficient of Friction | ||||||||||||||

| * 75μ m film was made by curing under the nitrogen condition at UVA | ||||||||||||||

| 0.5J/cm2 with a Fusion D lamp,unless otherwise specified. UV | ||||||||||||||

| Dosemeter is by UV POWER PUCK®II from EIT.INC.USA. | ||||||||||||||

| Product Characteristics | |||||||||||||||

| Low volatile content, environmentally friendly | |||||||||||||||

| Faster cure speed by UV-LED, energy efficient | |||||||||||||||

| Combining with RT series primary coating and inks for even better results | |||||||||||||||

| Excellent process parameters, good for non-helium, and wet-on-wet drawing process |

| Product Specification | ||||||||||||||

| No. | Properties | Units | Standards | |||||||||||

| Before Curing (Liquid) | ||||||||||||||

| 1 | Viscosity,25ºC | mPa.s | 5800-6600 | |||||||||||

| 2 | Density,20ºC | g/cm3 | 1.11-1.12 | |||||||||||

| 3 | Solid Content | % | >99 | |||||||||||

| 4 | Refractive Index,25ºC | 1.51±0.005 | ||||||||||||

| After Curing (Solid) | ||||||||||||||

| 5 | Glass Transition Temperature | ºC | ≥50 | |||||||||||

| (DMA) | ||||||||||||||

| 6 | Secant Modules,2.5% | MPa | 900-1100 | |||||||||||

| 7 | Elongation | % | 12月28日 | |||||||||||

| 8 | Tensile Strength | MPa | 35-45 | |||||||||||

| 9 | Cure speed when RAU95% | J/cm2 | ≥1.2 | |||||||||||

| 10 | Oxygen generation(80ºC , 24h) | ul/g | ≤0.2 | |||||||||||

| 11 | Weight Change | 88ºC 8weeks | % | <-1.0 | ||||||||||

| 125ºC 8weeks | <-4.6 | |||||||||||||

| 12 | (15g/m2 on PE ) | >0.20 | ||||||||||||

| Coefficient of Friction | ||||||||||||||

| * 75μ m film was made by curing under the nitrogen condition at UVA | ||||||||||||||

| 0.5J/cm2 with a Fusion D lamp,unless otherwise specified. UV | ||||||||||||||

| Dosemeter is by UV POWER PUCK®II from EIT.INC.USA. | ||||||||||||||