Shanghai Gengyun Industrial Co., Ltd

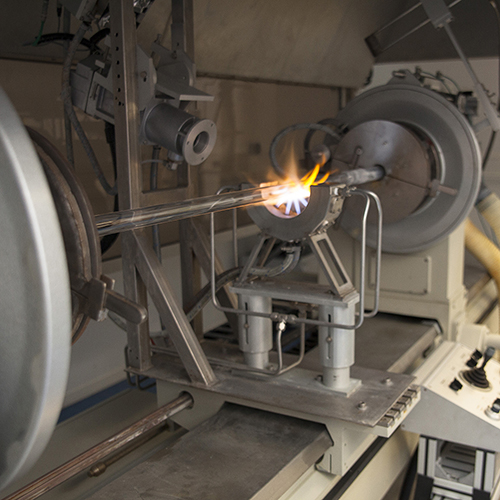

Equipment for Fiber Preform Rod

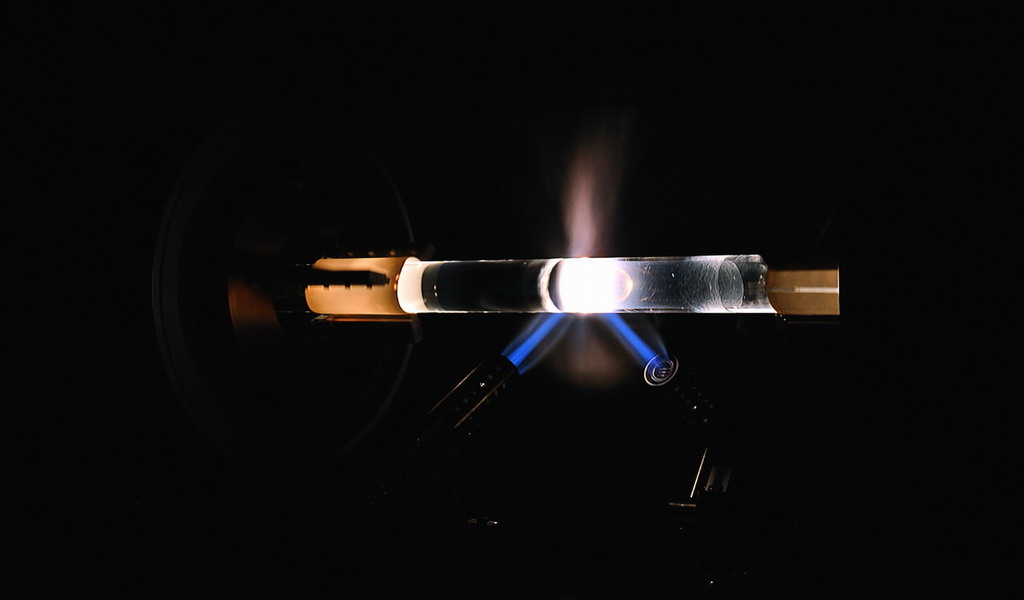

MCVD is the abbreviation for Modified Chemical Vapor Deposition, translated as Improved Chemical Vapor Deposition. The production method of prefabricated rods was first proposed by Bell Laboratories in the United States and the University of Southampton in the early 1970s, and was invented by Bell Laboratories in 1973. Over the past 40 years, authors around the world have published numerous articles on this process, with the most important being comprehensive reviews by scientists from Bell Laboratories in 1982 and 1985, providing readers with systematic reference materials. Given the strong flexibility of MCVD equipment in preparing different types of fiber preforms, it has become one of the four main methods for producing high-quality communication fiber preforms, and has a wide range of applications in the manufacturing of special fiber preforms for sensing and lasers.

The MCVD method can deposit higher purity silicon dioxide (Si0,) on the inner wall of high-quality (high-purity, low moisture, low impurity) quartz tubes (usually referred to as lining tubes), and add other high-purity substances that can change the refractive index or viscosity of the glass body, such as germanium dioxide (GeO,), phosphorus pentoxide (P, O,), silicon oxyfluoride (SiO, F), etc., to form core and cladding layers with different refractive indices, in order to achieve total reflection, low loss, high capacity, and other effects when optical signals propagate in the fiber core.

| The main advantages of the prefabricated rod manufacturing method based on MCVD equipment |

| 1.Internal sedimentation in a fully enclosed system to prevent impurities from entering; 2.Easy to achieve complex refractive index distribution; 3.The equipment is simple and easy to operate, with low initial investment; 4.Flexible technology, suitable for manufacturing a variety of optical fibers; 5.Product equipment available |