Shanghai Gengyun Industrial Co., Ltd

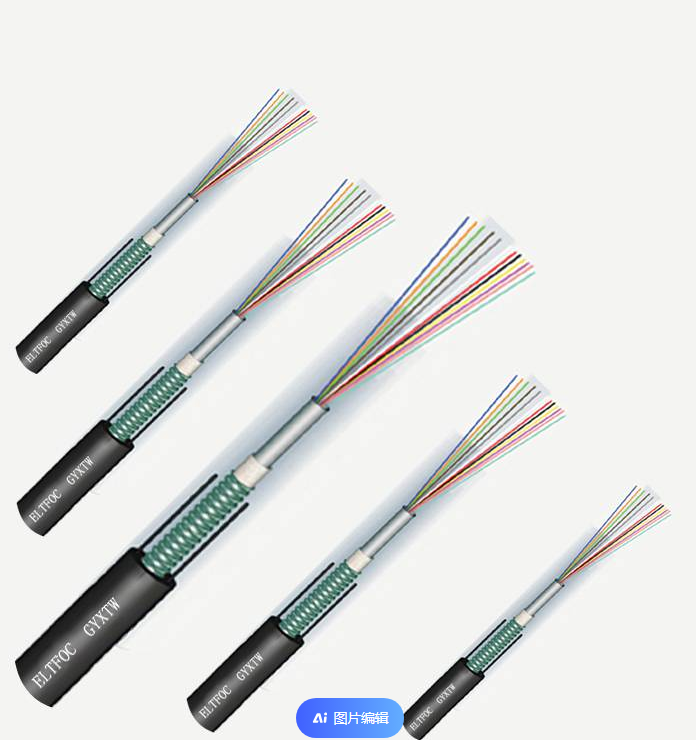

Outdoor Central Loose Tube Unitube 2 4 6 8 core Optical Fiber Cable

Categories Central Unitube Cable, Outdoor Fiber Optic Cable, Products

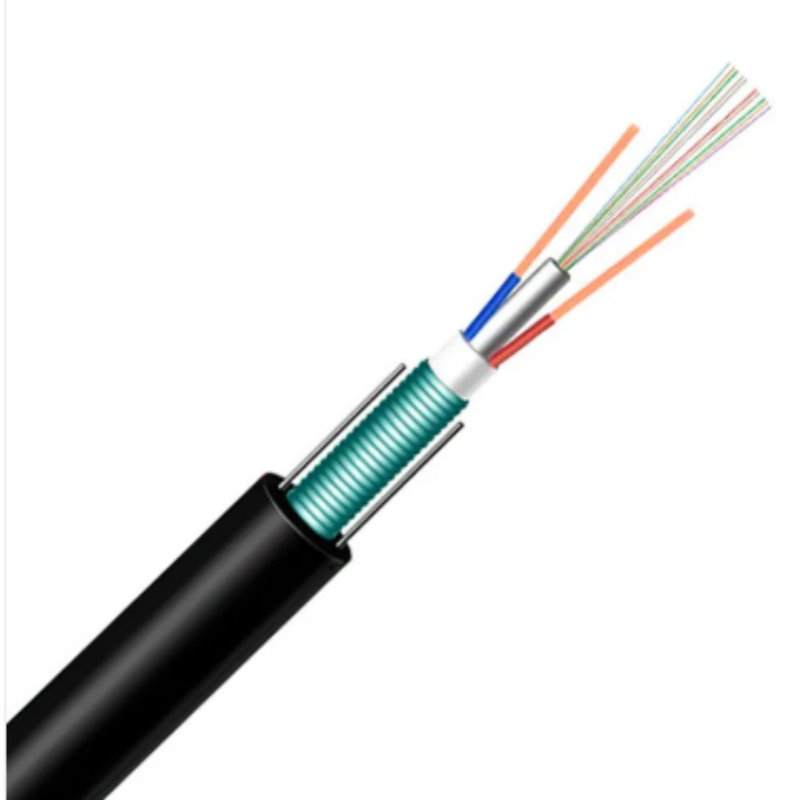

GYDXTW (Optical fiber ribbon, Structure with central tube, Steel-polyethylene adhesive sheath)/T-FC408

Product Srandard

Meet YD/T 981. 2-2009 Optical fiber ribbon cable for access network;

Product Specification

| Fiber Count | Structure | Diameter | Weight (kg/km) | Tensile(N) | Crush(N) | Bending Radius(mm) | |||

| (mm) | Long term | Short term | Long term | Short term | Static | Dynamic | |||

| 48 | Central tube | 12.5 | 163 | 600 | 1500 | 300 | 1000 | 10D | 20D |

| 60 | Central tube | 13.4 | 184 | 600 | 1500 | 300 | 1000 | 10D | 20D |

| 72 | Central tube | 13.4 | 184 | 600 | 1500 | 300 | 1000 | 10D | 20D |

| 84 | Central tube | 13.9 | 195 | 600 | 0.8G | 300 | 1000 | 10D | 20D |

| 96 | Central tube | 13.9 | 196 | 600 | 0.8G | 300 | 1000 | 10D | 20D |

| 108 | Central tube | 14.7 | 214 | 600 | 0.8G | 300 | 1000 | 10D | 20D |

| 120 | Central tube | 14.7 | 215 | 600 | 0.8G | 300 | 1000 | 10D | 20D |

| 132 | Central tube | 15.2 | 230 | 600 | 0.8G | 300 | 1000 | 10D | 20D |

| 144 | Central tube | 15.2 | 230 | 600 | 0.8G | 300 | 1000 | 10D | 20D |

| 168 | Central tube | 15.9 | 248 | 600 | 0.8G | 300 | 1000 | 10D | 20D |

| 192 | Central tube | 16.5 | 267 | 600 | 0.8G | 300 | 1000 | 10D | 20D |

| 216 | Central tube | 17 | 280 | 600 | 0.8G | 300 | 1000 | 10D | 20D |

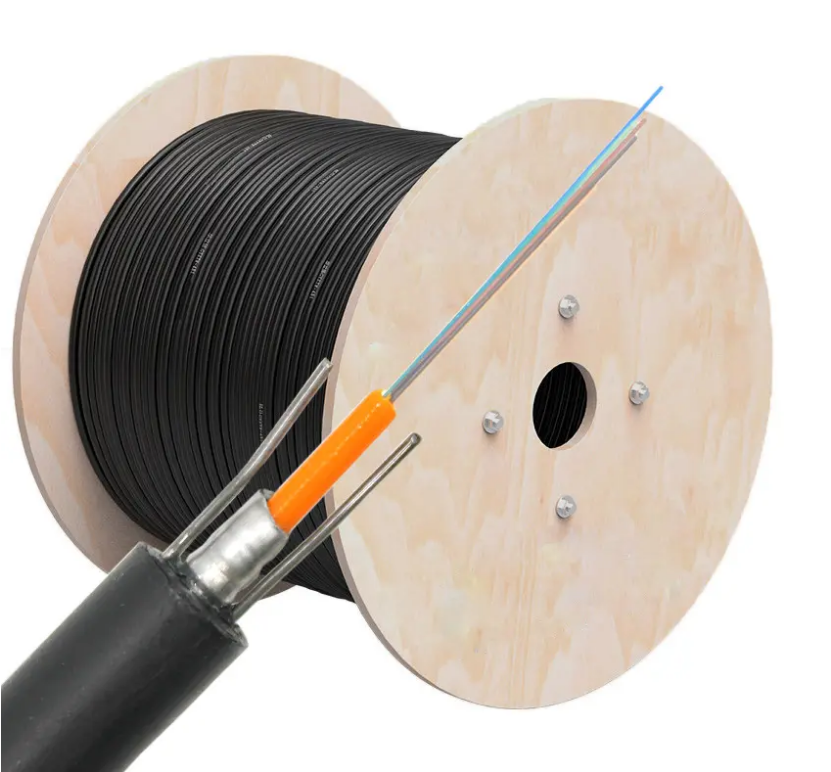

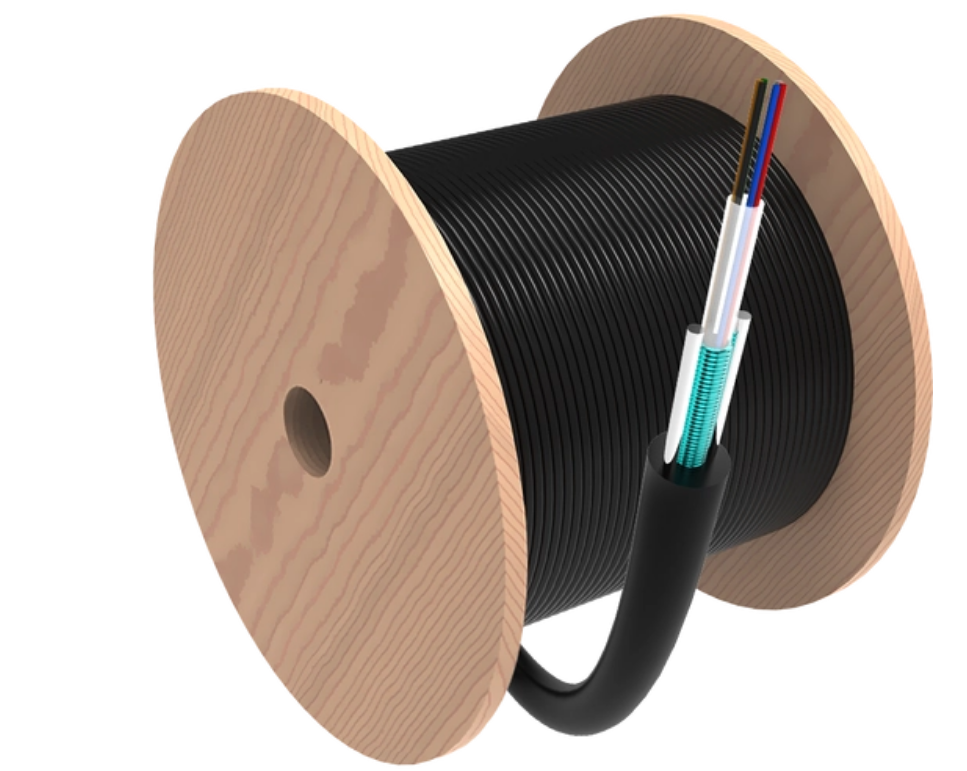

Package of Central Loose Tube Fiber Cable

Standard Export Packing