Shanghai Gengyun Industrial Co., Ltd

Pickling and Corrosion Equiment for Fiber Preform

Due to the trend of large-scale development of fiber optic preforms, the intermediate process and related turnover processes of preform production have become more complex, leading to a significant increase in the probability of secondary pollution on the surface of preforms and during their processing and assembly.

Although the production and transportation process of fiber optic preforms is carried out in a relatively clean environment, the entire process is exposed to the air, and the surface will still be contaminated to a certain extent, such as some impurities or particles on the surface and surface pollution caused by other factors. The pollution on the surface of fiber optic preforms can be gas, liquid, or solid, which can exist in the form of membranes or particles. From a chemical perspective, these pollutants can be in an ionic or covalent state, either inorganic or organic.

In addition to pollutants, there are defects on the surface of prefabricated rods mainly manifested as microcracks. During the drawing process, when the external stress of the optical fiber is greater than the critical value of microcrack propagation, it will cause crack propagation and lead to fiber fracture. In addition, surface pollutants during the melting and drawing process of prefabricated rods can also exacerbate crack propagation, leading to the fracture of bare optical fibers.

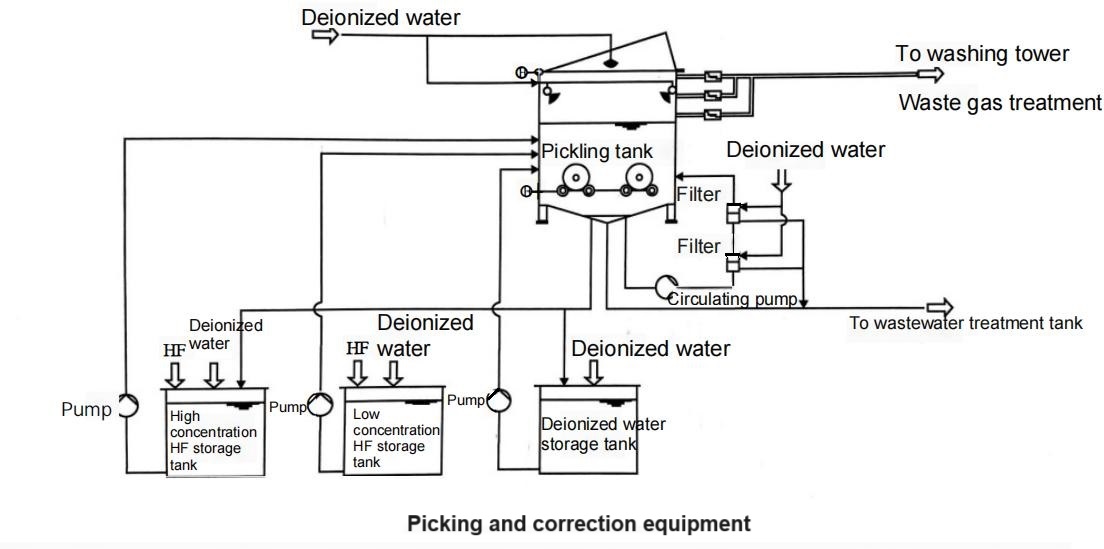

Therefore, if pollutants and surface defects cannot be effectively controlled before the fiber optic preform is drawn, it will directly affect the optical and mechanical properties of the produced fiber, thereby reducing the production qualification rate and causing an increase in manufacturing costs. At present, in the production process, additional treatment is carried out on the surface of optical fiber preforms through ultrasonic cleaning and acid washing, which can effectively remove defects and impurities on the surface of preforms, ensuring the smooth and efficient conversion of optical fiber preforms into optical fiber products.

Finally, after acid washing treatment, the fiber optic preform will be diluted and cleaned with deionized water to remove the residual acid on the surface. Therefore, a large amount of deionized water will remain on the surface of the preform or the quartz material used for assembling the preform. It is necessary to dry the preform to completely remove the deionized water from the inside and outside of the preform, otherwise it will have a serious impact on the performance of the fiber optic.

There are many commonly used surface treatment methods for prefabricated rods, which can be summarized as solvent cleaning, ultrasonic cleaning, acid cleaning(pickling), and flame polishing.

Pickling and corrosion

The acid used in acid pickling of fiber optic preforms is hydrofluoric acid (HF), and this process of treating fiber optic preforms with hydrofluoric acid is commonly referred to as corrosion process in fiber optic preform production.