Shanghai Gengyun Industrial Co., Ltd

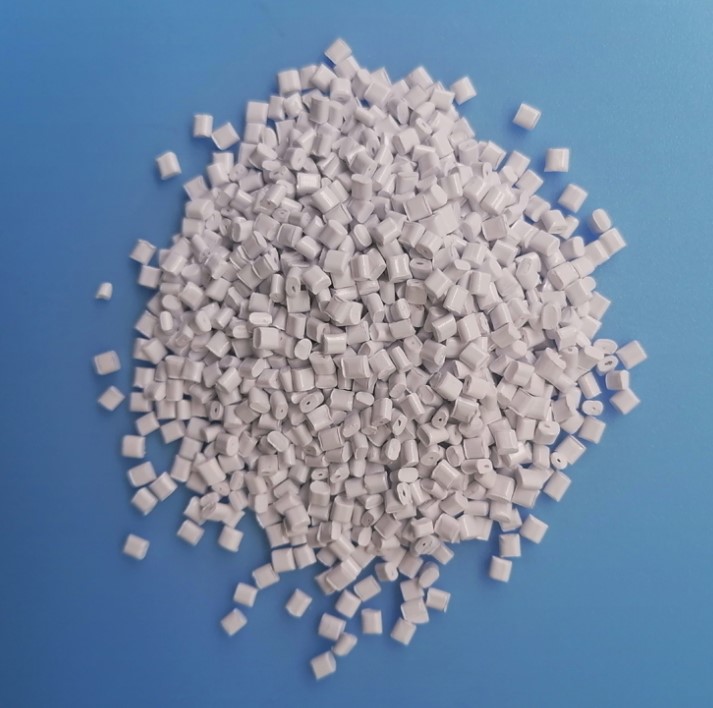

Fiber optic cable Plastic Pellets

Polycarbonate is an excellent secondary coating material for optical fibers. In particular, it has the characteristics of high temperature resistance, high strength and small linear expansion coefficient. Polycarbonate (PC) plastic material is widely used in non-metallic air-blown micro cables, high temperature resistant optical cables, etc.

Polycarbonate, referred to as PC. Polycarbonate has excellent comprehensive properties, especially outstanding impact resistance, transparency and dimensional stability. Secondly, it also has excellent mechanical strength and electrical insulation. Polycarbonate Plastic has a wide operating temperature range (-60~120℃), which is unmatched by other engineering plastics. Since industrial production, the output of polycarbonate plastic in engineering plastics is second only to polyamide (PA), maintaining an average annual growth rate of 9%. Polycarbonate is an excellent secondary coating material for optical fibers. In particular, it has the characteristics of high temperature resistance, high strength and small linear expansion coefficient. Polycarbonate PC material is widely used in non-metallic air-blown micro cables, high temperature resistant optical cables, etc.

Polycarbonate resin can be processed through various methods such as injection molding, extrusion molding, blow molding, and injection blown molding.

When used as a material for manufacturing optical fibers and cables, extrusion molding technology is mainly used.

Polycarbonate Plastic Technology Parameters

| Performance: | |||||||

| Polycarbonate has excellent comprehensive properties, which are unmatched by most thermoplastic plastics. | |||||||

| Item | Unit | Test Standard | Test Conditions | Standard Type | |||

| Low Viscosity | Medium Viscosity | High Viscosity | |||||

| Relative Density | ASTM D792 | 1.20 | 1.20 | 1.20 | |||

| Water Absorption Rate | ASTM D570 | 23℃ in water 24h | 0.20% | 0.20% | 0.20% | ||

| Transmittance | ASTM D1003 | thickness 3mm | 89% | 89% | 89% | ||

| Refractive Index | ASTM D542 | 1.585 | 1.585 | 1.585 | |||

| Tensile Strength | Yield | MPa | ASTM D638 | 62 | 61 | 60 | |

| Fracture | MPa | ASTM D638 | 78 | 81 | 84 | ||

| Tensile Modulus | MPa | ASTM D638 | 2130 | 2120 | 2100 | ||

| Elongation | Yield | ASTM D638 | 6% | 6% | 6% | ||

| Fracture | ASTM D638 | 140% | 140% | 130% | |||

| Bending Strength | MPa | ASTM D790 | 90 | 90 | 88 | ||

| Bending Modulus | MPa | ASTM D790 | 2260 | 2230 | 2200 | ||

| Compression Strength | MPa | ASTM D695 | 76 | 76 | 75 | ||

| Impact Strength | J/m | ASTM D256 | AISI, with a notch thickness of 3.2mm | 830 | 880 | 930 | |

| J/m | ASTM D256 | AISI, with a notch thickness of 6.4mm | 130 | 140 | 160 | ||

| Rockwell Hardness | ASTM D785 | M-scale | 77 | 77 | 77 | ||

| Forming Shrinkage Rate | ASTM D955 | Flow direction | 0.5~0.7 | 0.5~0.7 | 0.5~0.7 | ||

| Vertical direction | 0.5~0.7 | 0.5~0.7 | 0.50~0.7 | ||||

| Hot Deformation Temperature | c | ASTM D048 | Load 0.451MPa | 142 | 143 | 146 | |

| Load 1.813MPa | 132 | 133 | 136 | ||||

| Coefficient of Linear Expansion | ×10~³/℃ | ASTM D696 | Flow direction | 7 | 7 | 7 | |

| Vertical method | 7 | 7 | 7 | ||||

| Dielectric Strength | kV/mm | ASTM D149 | Quick pressurization value thickness1.6mm | 30 | 30 | 30 | |

| Volume Resistivity | ×10¹⁶Ω ·cm | ASTM D257 | 3 | 3 | 3 | ||

| Dielectric Constant | ASTM D150 | 60Hz | 2.95 | 2.95 | 2.95 | ||

| 106 Hz | 2.9 | 2.9 | 2.9 | ||||

| Positive Average Dielectric Loss Angle | ASTM D15C | 60Hz | 0.0004 | 0.0004 | 0.0004 | ||

| 106 Hz | 0.009 | 0.009 | 0.009 | ||||

| Arc Resistance | S | ASTM D495 | 110 | 110 | 110 | ||

| Conductive Track Resistance (CT) | V | IEC.112 | 300 | 300 | 300 | ||

| Flame Retardancy | UL 94 | thickness 1.47mm | V-2 | V-2 | V-2 | ||

| thickness 3.05mm | V-2 | V-2 | V-2 | ||||

| Temperature Index | ℃ | UL7468 | Electrical thickness 1.47mm | 125 | 125 | 125 | |

| Impact type thickness 1.47mm | 115 | 115 | 115 | ||||

| Non impact thickness 1.47mm | 125 | 125 | 125 | ||||

| Note: The values listed in this table are typical values and are for reference only. | |||||||