Shanghai Gengyun Industrial Co., Ltd

Ratproof Antproof Cable Sheating Compound

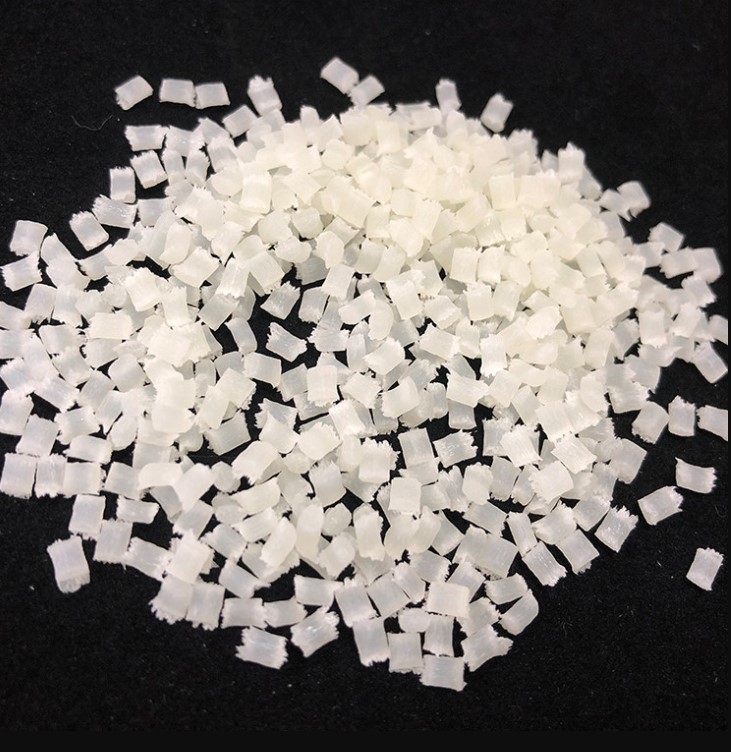

Environmental friendly rat-proof and ant-proof nylon cable material Polyamide(PA) has excellent mechanical property,fine ant-proof. It also has rat-proof performance, low temperature performance and excellent extrusion property.

Environmental friendly rat-proof and ant-proof nylon cable coating material Polyamide (PA) Plastic has excellent mechanical property,fine ant-proof. It also has rat-proof performance,low temperature performance and excellent extrusion property.

| Type and Application: | ||

| Type | Product | Application |

| T-PA001-A-7025 | Environmental friendly ratproof and antproof nylon cable material | For optical cable jacket |

| T-PA001-A-7025L | Environmental friendly ratproof and antproof nylon cable material | For optical cable jacket |

| T-PA001-A-7625 | Environmental friendly ratproof and antproof nylon cable material | For optical cable jacket |

| T-PA001-A-7125 | Environmental friendly ratproof and antproof nylon12 cable material | For optical cable jacket |

| T-PA001-A-7525 | Environmental friendly ratproof and antproof nylon cable material | For optical cable jacket |

Processing Parameter

| The following temperature profile of extruder is recommended: | |||||||

| Zone | Zone1 | Zone2 | Zone3 | Zone4 | Zone5 | Head | Die |

| Temperature ºC | 210 | 225 | 235 | 240 | 240 | 240 | 235 |

Cable Coating Material Polyamide Plastic Technology Parameters

| Properties | ||||||||

| NO. | ltem | Unit | Typical value | Test method | ||||

| T-PA001-A-7025 | T-PA001-A-7025L | T-PA001-A-7625 | T-PA001-A-7125 | T-PA001-A-7525 | ||||

| 1 | Density | g/cm | 1.15 | 1.15 | 1.35 | 1.12 | 1.36 | ASTM D1505 |

| 2 | Melting point | C | 210 | 210 | 210 | 190 | 210 | ASTM D3418 |

| 3 | Melting Index | g/10min | 6 | 7 | 3 | 4 | 3 | ASTM D1238 |

| 4 | Tensile Strength | MPa | 73 | 65 | 50 | 60 | 50 | ASTM D638 |

| 5 | Elongation at | % | 300 | 120 | 120 | 300 | 120 | ASTM D638 |

| Break | ||||||||

| 6 | Thermal Aging | C x day | 158 ×7 | 158×7 | 158×7 | 158×7 | 158 x 7 | ASTM D638 |

| Property | ||||||||

| 6.1 | Variation on | % | 98 | 96 | 98 | 90 | 98 | |

| Tensile Strength | ||||||||

| 6.2 | Variation on | % | 96 | 92 | 96 | 92 | 96 | |

| Elongation | ||||||||

| 7 | 0.45MPa | ºC | 180 | 180 | 180 | 180 | 180 | ASTM D648 |

| Load deformation | ||||||||

| temperature | ||||||||

| 8 | IZOD impact | MPa | 40 | 38 | 30 | 50 | 30 | ASTM D256 |

| strength | ||||||||

| 9 | Rockwell | R | 118 | 118 | 120 | 116 | 120 | ASTM D785 |

| hardness | ||||||||

| 10 | Non cracking | ºC | -45 | -45 | -30 | -45 | -30 | IEC 60811-1-4 |

| temperature | ||||||||

| 11 | Volume | Ω.m | 1.0×1014 | 1.0×1014 | 1.0×1014 | 1.0×1014 | 1.0×1014 | ASTM D257 |

| Resistivity at | ||||||||

| 20ºC | ||||||||

| 12 | Dielectric | MV/m | 25 | 25 | 25 | 25 | 25 | ASTM D148 |

| constant | ||||||||

Strorage and Transport

| Product adopts aluminum plastic compound pocket with outer paper-plastic lamination bag.Net weight is 25kg.

To be stored in dry and ventilated warehouse. After long-term storage, drying treatment is required; Drying temperature is 100C. Drying time is 3 hours. |