Shanghai Gengyun Industrial Co., Ltd

Ultrasonic Cleaning Machine for Fiber Preform

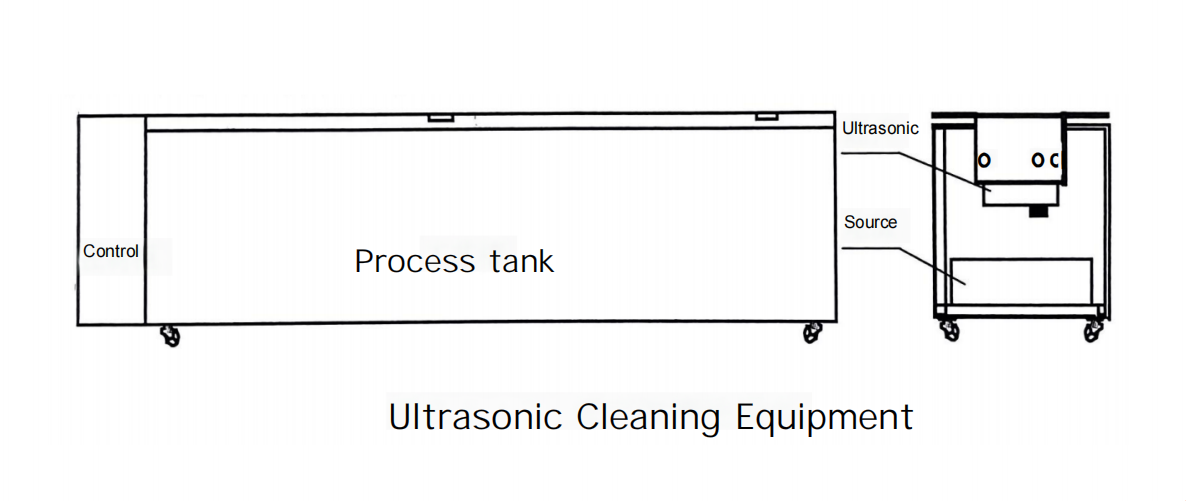

At present, in the production process, additional treatment is carried out on the surface of optical fiber preforms through ultrasonic cleaning machine and acid washing machine. Which can effectively remove defects and impurities on the surface of preforms. This ensuring the smooth and efficient conversion of optical fiber preforms into optical fiber products.

Finally, after acid washing treatment, the fiber optic preform will be diluted. And cleaned with deionized water to remove the residual acid on the surface. Therefore, a large amount of deionized water will remain on the surface of the preform. Or the quartz material used for assembling the preform. It is necessary to dry the preform to completely remove the deionized water from the inside and outside of the preform. Otherwise it will have a serious impact on the performance of the fiber optic.

There are many commonly used surface treatment methods for prefabricated rods. Which can be summarized as solvent cleaning, ultrasonic cleaning, acid cleaning(pickling), and flame polishing.

Advantage of Ultrasonic Cleaning Machine

Ultrasonic cleaning can remove strong adhesive pollutants on the surface of fiber optic preforms. This cleaning method is a strong physical cleaning method, which continuously vibrates through the action of ultrasonic waves to gradually loosen and detach the pollutants adhering to the surface of the prefabricated rod.