Shanghai Gengyun Industrial Co., Ltd

PCResin Injection Transparent Polycarbonate ofc

Categories Coating Materials, PC, Raw and Accessory Materials

Polycarbonate pc thermoplastic engineering plastics have lower density and lighter weight. PC has high heat resistance and can maintain stable physical properties within a certain high temperature range. Its heat deformation temperature is high and it can maintain shape and size stability at higher temperatures. Its high strength and impact resistance make it an ideal material for manufacturing electronic devices.

Feature

- Good heat resistance;

- Good transparency;

- Polycarbonate pc has strong impact resistance;

- Good flame retardancy;

- Low water absorption;

- Excellent electrical insulation;

Application of Polycarbonate PC Material

- Ultraviolet coating material for cables;

- Widely used in building materials such as solar panels, thermal insulation layers, etc.;

- PC has high transparency and good UV resistance. Therefore, it is widely used in the manufacture of optical products such as eyeglass lenses, camera lenses, and solar panels.

Technology Parameters

| Features | ·Medium Viscosity | ·Easy Release | ||

| Uses | ·General Purpose | |||

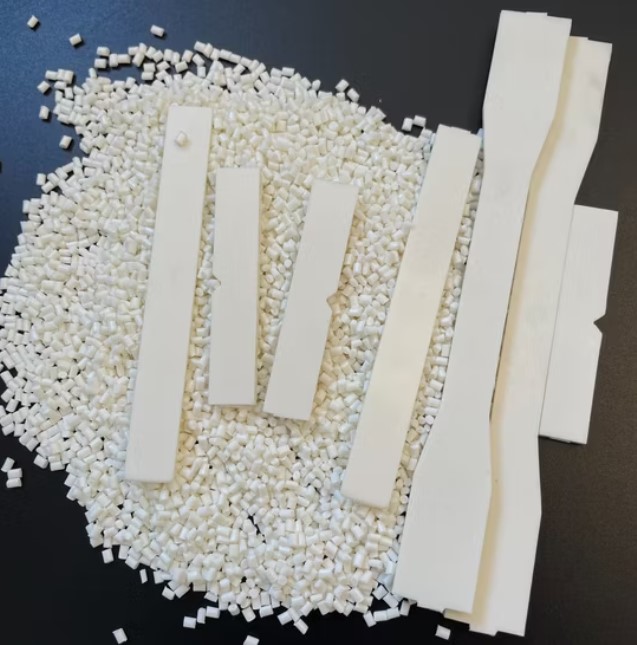

| Appearance | ·Clear/Transparent | |||

| Forms | ·Pellets | |||

| Processing Method | ·Injection Molding | |||

| Typical Properties | ||||

| Test Method | Test Condition | Unit | Typical Value | |

| Physical | ||||

| Melt Flow Index | ASTM D1238 | 300ºC/1.2Kg | g/10min | 9.5 |

| Mold Shrinkage | ASTM D955 | – | % | 0.5-0.7 |

| WaterAbsorption | ASTM D570 | 23ºC,24h | % | 0.2 |

| Density | ASTM D792 | – | g/cm³ | 1.2 |

| Mechanical | ||||

| Stress at Break | ASTM D638 | 50mm/min | MPa | 72 |

| Tensile Modulus | ASTM D638 | 1mm/min | MPa | 2300 |

| Yield Stress | ASTM D638 | 50mm/min | MPa | 65 |

| Yield Strain | ASTM D638 | 50mm/min | % | 6 |

| Strain at Break | ASTM D638 | 50mm/min | % | 120 |

| Flexural Strength | ASTM D790 | 2mm/min | MPa | 97 |

| Flexural Modulus | ASTM D790 | 2mm/min | MPa | 2300 |

| Izod Notched Impact Strength | ASTM D256 | 23ºC | J/m | 800 |

| Thermal | ||||

| Heat Distortion Temp. | ASTM D648 | 1.82MPa;3.2mm | ºC | 130 |

| Vicat Softening Temp. | ASTM D1525 | 120ºC/h;50N | ºC | 150 |

| Date of issue: Mar. 01, 2021 | CLARNATE® | |||

| Version: 4.0 | ||||

| 1 / 3 | ||||

| CLARNATE®A1105 | ||||

| Typical Properties | ||||

| Test Method | Test Condition | Unit | Typical Value | |

| Optical | ||||

| Haze | ASTM D1003 | 3mm | % | <0.8 |

| Light Transmittance | ASTM D1003 | 3mm | % | 89 |

| Refractive Index | ASTM D542 | – | – | 1.586 |

| Flammability | ||||

| Flame Rating | UL94 | 3mm | – | HB |

| UL94 | 1.5mm | – | V2 | |

| Electrical | ||||

| Relative Permittivity | IEC 60250 | 100Hz | – | 3.1 |

| IEC 60250 | 1MHz | – | 3 | |

| Dissipation Factor | IEC 60250 | 100Hz | 10-4 | 5 |

| IEC 60250 | 1MHz | 10-4 | 90 | |

| Volume Resistivity | IEC 60093 | – | Ω·m | 1014 |

| Surface Resistivity | IEC 60093 | – | Ω | 1016 |

| Electric Strength | IEC 60243-1 | 1mm | KV/mm | 34 |

| Comparative Tracking Index | IEC 60112 | SolutionA | V | 250 |

| Processing Condition |