Shanghai Gengyun Industrial Co., Ltd

Waste Gas Treatment Equipment for Fiber

In the process of preparing optical fiber preforms using hydrolysis methods (such as VAD and OVD processes), a large amount of corrosive gases such as Cl and HC1 are generated in the exhaust gas, which also contains a large amount of undeposited Si0 and dust. This type of exhaust gas must be purified by exhaust treatment equipment before it can be discharged into the atmosphere.

| The main sources and characteristics of exhaust gas in the production process of prefabricated rods are: 1. Prefabricated rod cladding deposition equipment (OVD): high temperature, about 120 ℃~260 ℃; Containing high concentrations of Si0, dust, and HC1 gas. 2. Prefabricated core layer deposition equipment (VAD): The concentration of SiO, dust, and HC1 gas is relatively low. Dehydration and sintering equipment: mainly Cl. |

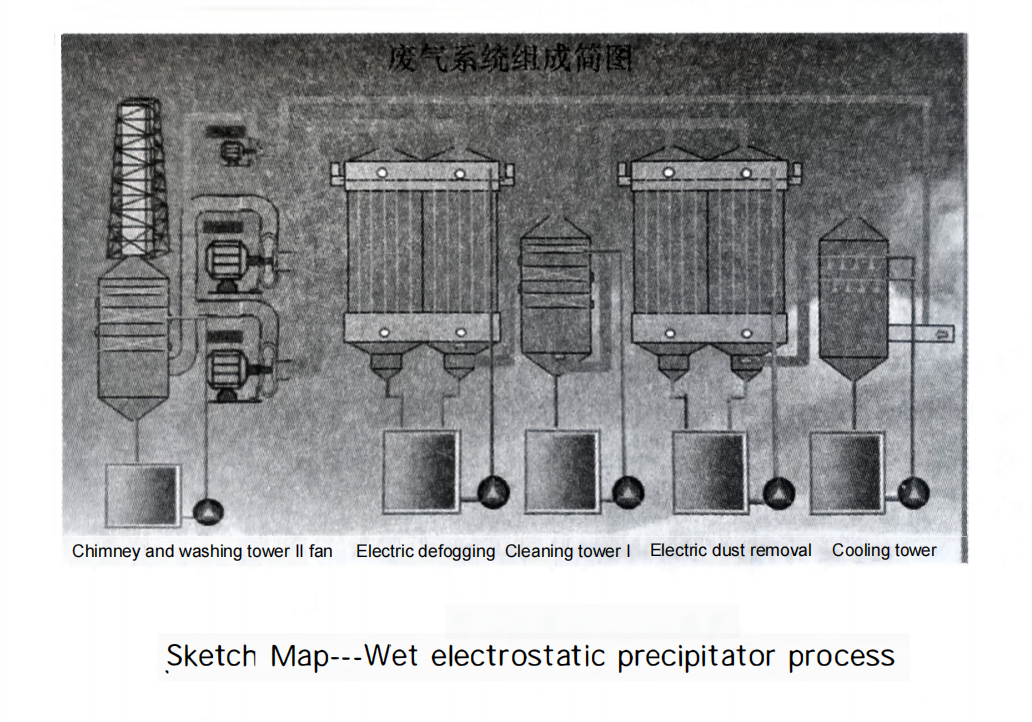

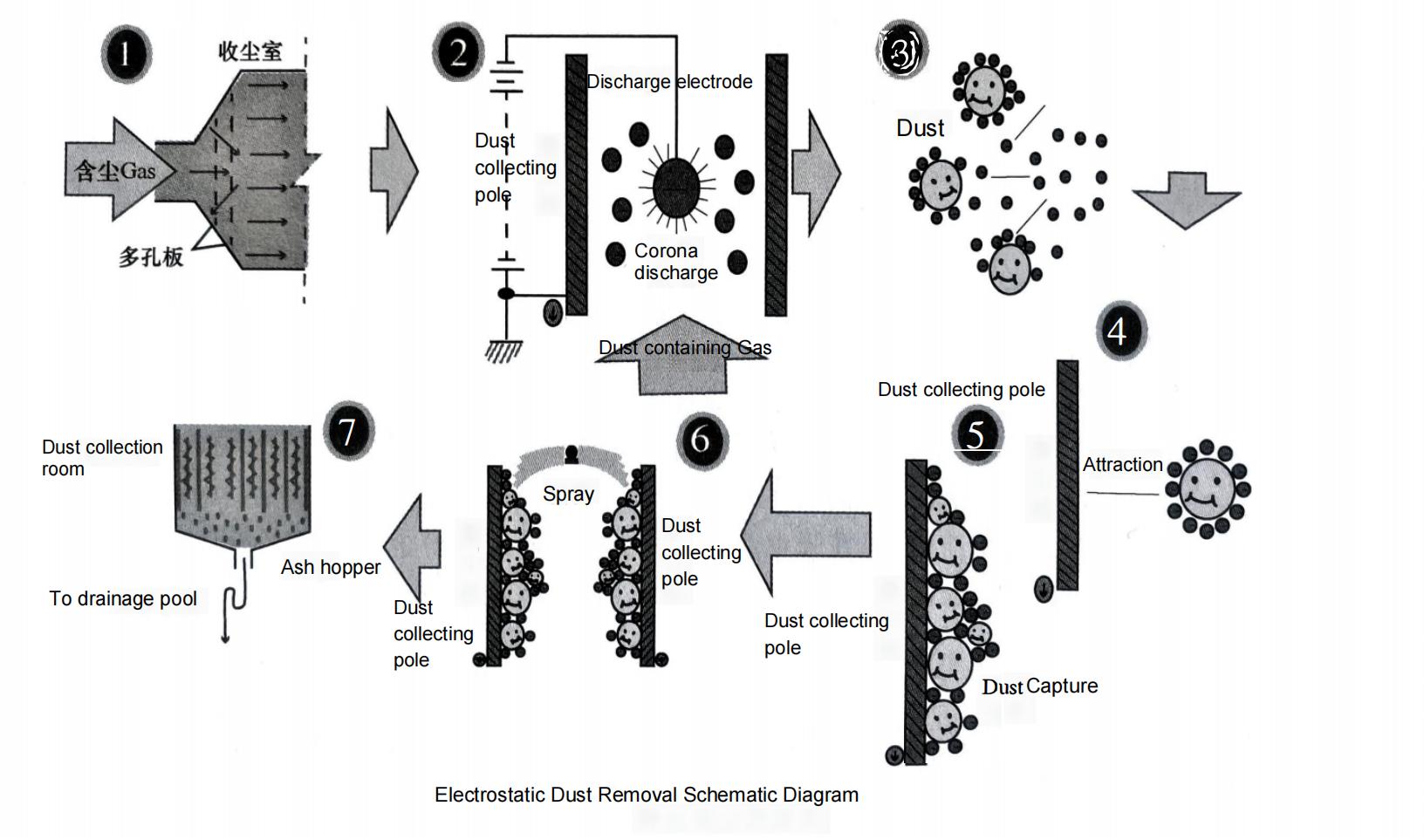

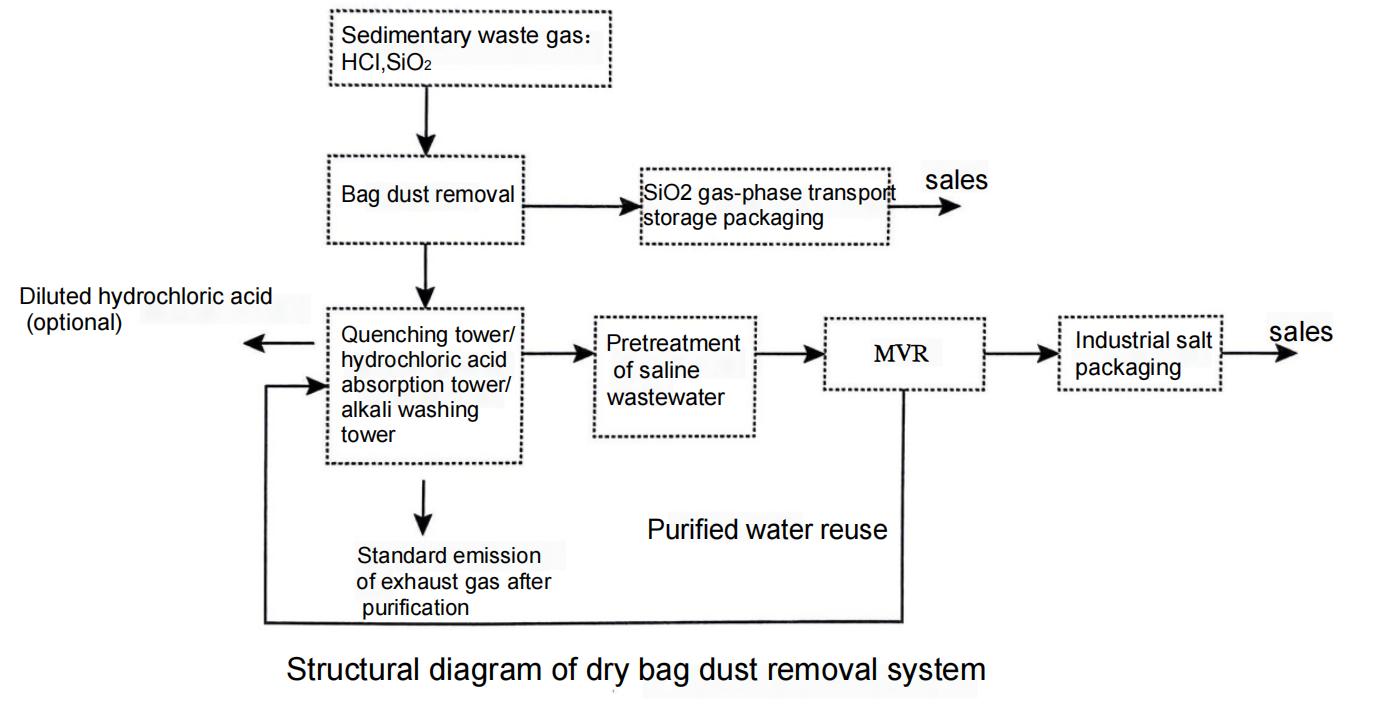

| The current mainstream exhaust gas treatment method is wet high-pressure electrostatic precipitator. The basic process is: exhaust gas guide → cooling tower → first stage wet electrostatic precipitator → washing tower → second stage wet electrostatic precipitator with an induced draft fan → exhaust pipe → standard gas emission. Through the above treatment process, SiO and dust in the exhaust gas are absorbed into the wastewater, and HC is neutralized by alkalis (such as NaOH). The treatment process of wastewater generated from tail gas treatment is as follows: wastewater introduction → waste acid tank → waste alkali tank → reduction → degassing → neutralization → flocculation → coagulation → sedimentation. The clear liquid meets the standard for discharge or reuse; After sedimentation, the sludge is filtered through a row of slag pressure filtration and then transported for treatment. The main advantages of wet high-pressure electrostatic precipitator are: high processing efficiency, which can achieve extremely low dust emission indicators; The system has been validated by years of application, mature, reliable, and easy to operate; Reduced system pressure and lower energy consumption; All non-metallic corrosion-resistant materials are used, which can effectively address the problem of hydrogen chloride corrosion. In recent years, with the improvement of filtering materials, dry bag dust removal treatment systems have emerged. The basic process is as follows: exhaust gas introduction – gas process control – bag dust collector – cooling tower – hydrochloric acid recovery tower – refining tower – induced draft fan – exhaust pipe – standard gas discharge. The auxiliary equipment includes dust conveying and storage systems. The main advantages of Qianshi cloth bag removal are: Si0, powder can be recovered separately (there is a possibility of reuse); Recyclable dilute hydrochloric acid. |