Shanghai Gengyun Industrial Co., Ltd

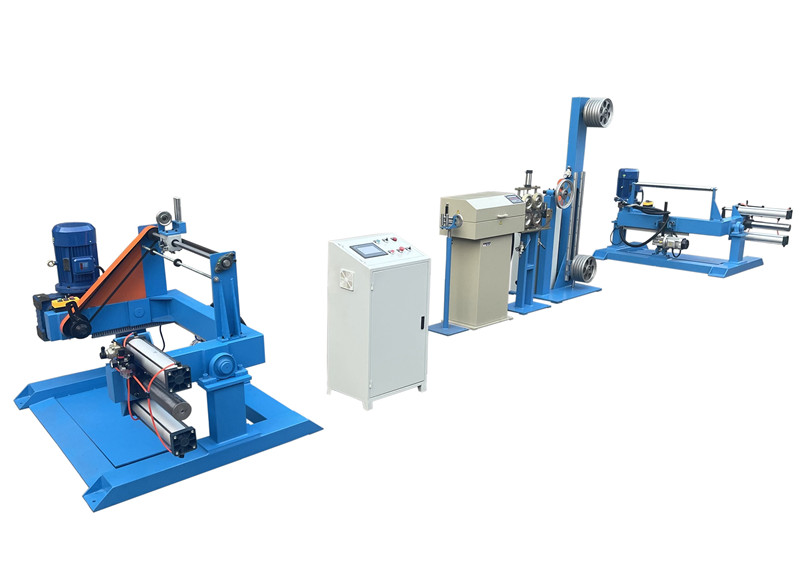

Wire & Steel Tube/Pipe & Cable Rewinding Machine

The OPGW/OPPC structure contains optical units and metal wires, which need to be wound on a tool tray suitable for the cable laying machine’s winding cage during cable laying. In order to reduce material loss, these wires are often in large trays (or bundles) when entering the factory, often poorly arranged and under uneven stress, and may also have joints. Therefore, it is necessary to use a wire rewinding machine to match these wires. The auxiliary equipment of OPGW/OPPC mainly includes rewinding machines for wire, steel pipes, and finished cables.

Categories Auxiliary Equipment, Manufacturing Equipment

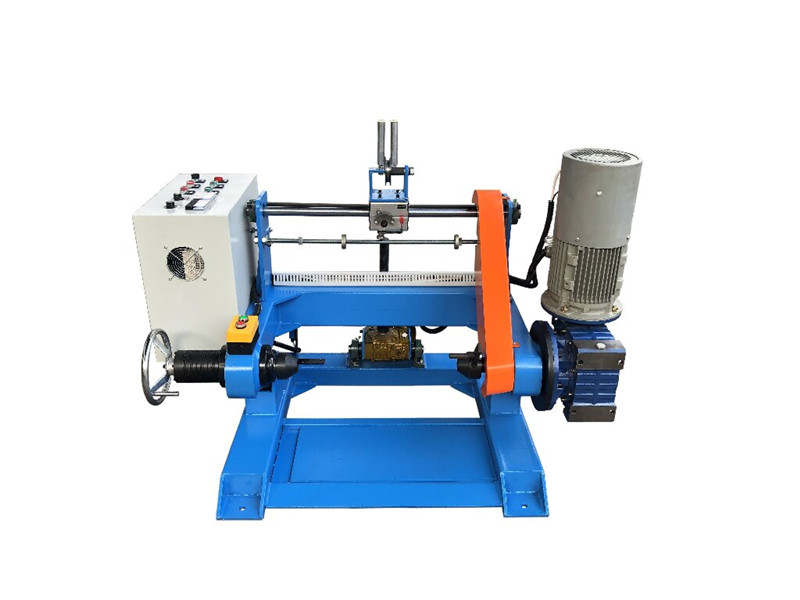

| Main Technical Parameters of Wire Rewinding Machine | |||

| No. | Item | Unit | Parameters |

| 1 | Maximum load capacity for pay-off | t | 3 |

| 2 | Pay-off reel specification | mm | φ1000,φ1250 |

| 3 | Maximum load capacity for take-up | kg | 600 |

| 4 | Take-up reel specification | mm | PN630 |

| 5 | Maximum take-up speed | m/min | 200 |

| 6 | Meter accuracy | —— | Better than 0 . 2% |

| 7 | Braking time | 8 | 5 (emergency), 30 (general) |

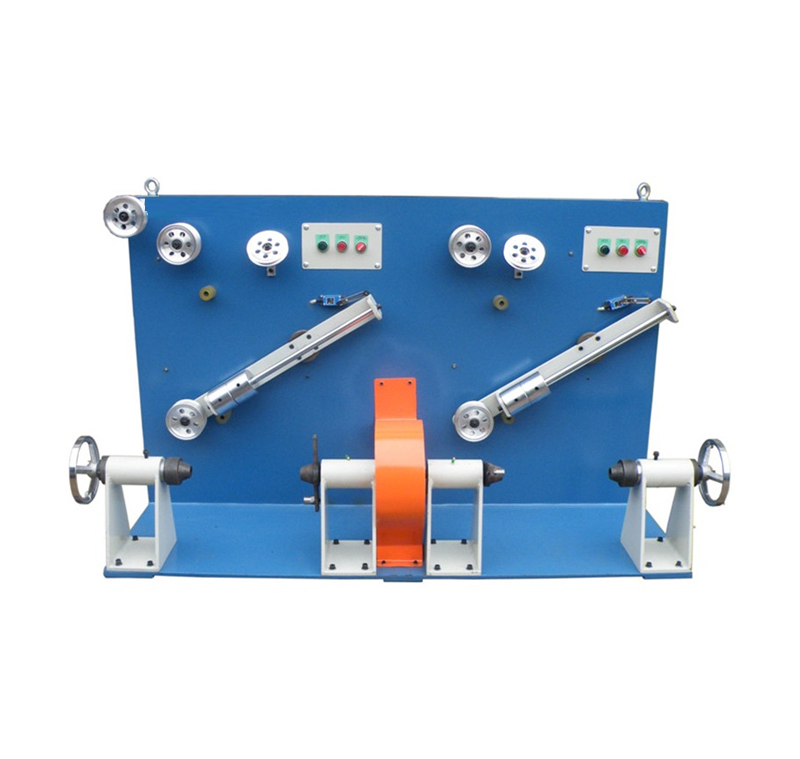

| Main Technical Conditions of Pay-Off Rack | |||

| No. | Item | Unit | Parameters |

| 1 | Dia.of Steel Pipe | mm | φ 1.2~4.0 |

| 2 | Maximum reel weight | kg | 500 |

| 3 | AC reduction motor | Reduction ratio 1:20 | |

| 4 | Maximum pay-off speed | m/min | 100 |

| 5 | Pay-off tension | N | (5~30)±1(Continuously adjustable) |

| 6 | Payout reel specification | mm | PN630,PN800,PN1000 |