Shanghai Gengyun Industrial Co., Ltd

What is a PLC Splice Closure? A Complete Guide to Fiber Splicing Protection

The Critical Role of Splicing Protection in Fiber Networks

In modern fiber optic networks, ensuring the long-term reliability of every connection point is essential. The PLC Splice Closure is a high-performance solution designed for this exact purpose. It acts as a vital node in the network’s physical layer, based on a philosophy of modularity and integration. This concept often aligns with that of an Integrated Fiber Optic Closure. Such designs combine crucial functions like fusion splicing, organized fiber storage, and robust environmental sealing into one compact, durable unit. This approach brings clear benefits by significantly improving deployment speed and simplifying future upkeep. Choosing the appropriate closure directly affects network uptime, operational costs, and ease of expansion.

- Understanding the Splicing Point as a Network Vulnerability

Every fusion splice—where two fiber ends are permanently joined—is a potential weak spot. While the joint itself is strong, the delicate glass fiber around it is highly vulnerable. Threats include moisture, physical pressure, temperature swings, and UV light. These can degrade signal quality or cause a complete break. A splice closure is more than just a container. It functions as a protective ecosystem. Its main goal is to create a stable, controlled environment. This shields the critical junctions for decades, ensuring the signal integrity the entire network relies on.

- Evolution Towards Integrated and Modular Designs

Early models were often simple sealed cans with little internal organization. Modern PLC Splice Closures represent a shift toward smarter infrastructure. The move to a modular architecture means technicians can easily configure internal trays on-site to match the fiber count and splice type. The trend toward integration combines previously separate elements like splice trays and slack storage—into one user-friendly system. This reduces installation time, minimizes errors, and provides a clear, organized layout. This clarity is invaluable for future repairs or network upgrades.

Technical Design: Deconstructing the Closure’s Architecture

The superior performance of a quality PLC Splice Closure comes from careful engineering in four key areas: external protection, environmental sealing, internal organization, and long-term resilience.

- Robust Housing and Mechanical Protection

The first line of defense is the outer shell. Housings are typically made from high-strength engineering plastics or corrosion-resistant metals. This material choice provides excellent compression resistance for buried installations and high impact resistance for aerial mounts. It also ensures long-term corrosion resistance against chemicals or salt spray. The shape is often designed for easy mounting on poles, in manholes, or inside cabinets.

- Advanced Sealing Technology for Environmental Isolation

Creating a perfect environmental seal is mandatory. Premium closures use reliable sealing mechanisms. Common types include mechanical compression with rubber gaskets or gel-blocking technology. These systems achieve high ingress protection ratings, typically IP68. An IP68 rating certifies the unit is dust-tight and can withstand continuous water immersion. This effectively blocks water, dust, and humidity—the leading causes of splice failure in outdoor environments.

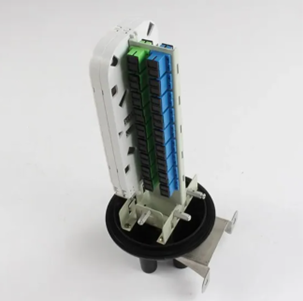

- High-Density, Organized Internal Fiber Management

The interior showcases the closure’s intelligent design. Modern units support high fiber counts, such as 144 or 288 fibers, using stackable, modular splice trays. A critical design rule is maintaining the minimum bend radius for stored fibers (typically >40mm). Respecting this radius prevents macro-bend loss and ensures optical performance meets standards. Clear labeling, ample slack storage, and intuitive paths prevent confusion and fiber damage during any work.

- Long-Term Stability Across Environmental Extremes

A closure must perform reliably for 20-30 years. This requires thoughtful thermal management—using materials and internal space that allow for expansion without stressing components. Exterior materials must have excellent UV resistance to prevent cracking from sun exposure. These features ensure stable operation across a wide temperature range, often from -40°C to +70°C, suitable for deployment in any climate.

Applications and Strategic Value in Network Deployment

The PLC Splice Closure is a versatile component found across all network layers. Its value extends beyond protection to impact total cost of ownership and network flexibility.

- Ubiquitous Application Across Network Layers

- Long-Haul & Trunk Networks: Used at regeneration points or to join cable lengths, protecting critical backbone splices.

- Metropolitan Area Networks (MAN): Common in ring architectures and links between central offices.

- FTTH Access Networks: The cornerstone of Fiber-to-the-Home deployment, used in street cabinets and at distribution points.

- Harsh Outdoor Environments: Designed for direct exposure in aerial, duct, and direct burial applications.

- Delivering Tangible Operational Benefits

For network operators, a high-quality closure translates to direct advantages:

- Reduced Failure Risk: Robust protection lowers the chance of environmentally caused splice failures.

- Lower Lifetime Costs: Easy re-entry and clear organization minimize repair and upgrade time and expense.

- Future-Proof Flexibility: Modular trays and spare capacity allow for straightforward network expansion without replacing the entire unit.

- Role in the Broader Physical Infrastructure Ecosystem

This device does not work alone. It is a key part of a larger physical infrastructure ecosystem. It connects with Optical Distribution Frames in central offices, fiber optic cabinets in the field, and various outdoor cables. Together, they form a robust, manageable foundation for the entire optical network.

The Future: Smarter Closures and Network Intelligence

The future of fiber infrastructure lies in adding data and intelligence. The next generation of closures is beginning this transformation.

- Integration of Monitoring and Sensing Capabilities

Future intelligent closures may include integrated sensors. These could monitor internal humidity, temperature, and access status. Data could be sent via low-power wireless links or through the fiber itself. This enables real-time health monitoring of the physical network.

- Enabling Proactive Maintenance and Smart O&M

This sensor data transforms network Operations and Maintenance (O&M). Instead of reactive repairs, operators can practice predictive maintenance. An alert for rising humidity would trigger an inspection before damage occurs. This shift toward Smart O&M improves reliability, cuts costs, and optimizes technician dispatch, paving the way for self-healing networks.

Conclusion

The PLC Splice Closure is far more than a simple protective box. It is a strategically engineered component that ensures the durability, reliability, and manageability of fiber optic networks. From its robust, sealed housing and organized internal management to its application across FTTH and metropolitan networks, it safeguards the critical points where light pulses travel. As networks evolve, the trend toward intelligent, sensor-equipped closures promises a future of proactive maintenance and smarter infrastructure. Selecting the right closure is a fundamental decision for anyone building or maintaining a resilient optical network

FAQs

1: What does “PLC” stand for in PLC Splice Closure? Is it related to Planar Lightwave Circuit splitters?

In this context, “PLC” most commonly stands for “Plastic,” referring to a common housing material, or is used as a general model series name by manufacturers. It is not directly related to Planar Lightwave Circuit (PLC) optical splitters. The closure is a protective housing, while a PLC splitter is a component that divides an optical signal. They are different products, though a closure may sometimes house and protect splitter modules inside.

2: How do I choose the right size (fiber count) for a splice closure?

- Count Existing Fibers: Total all fibers to be spliced inside the closure

- Plan for Future Growth: Add 20-50% spare capacity for future repairs or expansion.

- Consider Splice Type: Ribbon splicing allows higher density than single-fiber splicing. Choose trays designed for your method.

- Check Manufacturer Specs: Select a model rated for a count higher than your calculated total (e.g., choose a 144-fiber unit for 96 fibers).

Company Introduction: With over 20 years of deep industry expertise, we specialize in customizing and supplying solutions for optical fibers, cables, raw materials, and manufacturing equipment. We deliver reliable technical support and product services

About the Author:With 20 years of hands-on experience in optical transmission media, cable assemblies, and core substrate materials, we offer practical, expert insights grounded in full-industry-chain expertise.