Shanghai Gengyun Industrial Co., Ltd

What is a Photoelectric Hybrid Cable? Your Guide to Combined Power and Data

Solving Infrastructure Challenges with Integration

Modern applications, from factory automation to powering cell towers, often face a common problem: they traditionally need two separate cables—one for electricity and one for data. This approach complicates installations, raises costs, and introduces more potential failure points. The Photoelectric Hybrid Cable provides the solution. It integrates optical fibers for data and copper conductors for power within a single jacket. This “all-in-one” design enables the simultaneous transmission of energy and information, streamlining deployment and enhancing reliability.

- The Drawbacks of Separate Systems

Laying distinct power and communication lines requires multiple trenches or separate conduits. This increases material expenses, labor time, and the physical space required. Managing two independent systems also complicates maintenance. In demanding environments like industrial plants or remote sites, this duplication proves inefficient and risky. Electrical interference can disrupt data signals if cables lack proper spacing—an issue the integrated design inherently prevents.

- The Core Philosophy of Unified Design

The innovation centers on the cable’s unified structure. Imagine a single cable where some wires deliver electricity to run a device, while built-in fibers carry high-speed video or control signals. This is more than simple bundling; it is an engineered solution that protects all components together. This design philosophy transforms complex cabling into a streamlined, single-point solution. It perfectly suits powering and connecting devices like Remote Radio Units (RRUs), security cameras, and industrial sensors.

Technical Design and Key Advantages

The strength of a photoelectric hybrid cable stems from three main benefits: integrated construction, high operational reliability, and easier installation. These result from careful material selection and structural design.

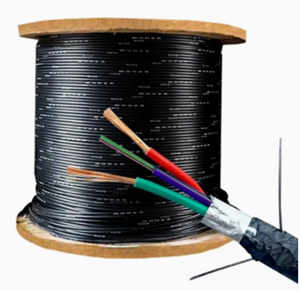

- Integrated Internal Construction

Inside the cable, different units work in unison. The optical unit protects delicate glass fibers, often employing a tight-buffered or loose-tube design to ensure low signal loss. The electrical unit consists of insulated copper wires, sized to carry the required current safely. These elements typically twist around a central strength member. The core incorporates water-blocking materials like gels or tapes, preventing moisture from damaging both power and data components over long distances.

- Durable Outer Protection

A tough outer sheath encases the integrated core. Common sheath materials include Polyurethane (PUR) for excellent flexibility and oil resistance in factories, or Polyethylene (PE) for superior weather and UV resistance outdoors. This jacket provides:

- Strong Mechanical Protection: High resistance to pulling, crushing, and bending during installation.

- Wide Environmental Tolerance: Stable performance in extreme temperatures (e.g., -40°C to +70°C) and resistance to chemicals.

- Enhanced Safety: Manufacturers can use flame-retardant or Low Smoke Zero Halogen (LSZH) materials for buildings or tunnels.

- Synergized Performance

This design ensures both power and data perform optimally without interference. The optical fibers naturally resist Electromagnetic Interference (EMI) from the adjacent power lines, a common problem for traditional copper data cables. Meanwhile, the power conductors gain extra durability from the overall cable structure. The result is a highly reliable, dual-purpose link for energy and communication.

Applications and Strategic Value

These cables deliver the greatest value in scenarios requiring both remote power and high-speed data, simplifying deployment and reducing long-term costs.

- Primary Use Cases

- Telecommunications & 5G Networks: Delivering DC power and fiber backhaul to Remote Radio Units (RRUs) on cell towers, simplifying site cabling dramatically.

- Industrial Automation: Connecting machinery, PLCs, and sensors on factory floors, reducing cable clutter and boosting reliability in electrically noisy environments.

- Remote Security & Monitoring: Powering and linking IP cameras and sensors for traffic, perimeter security, or infrastructure monitoring, often eliminating the need for local power outlets.

- New Energy Systems: Serving solar farms and wind power sites for data collection and control wiring over long distances in harsh conditions.

- Advantages Over Traditional Methods

Compared to laying separate power and data cables, the hybrid solution offers clear benefits:

- Lower Installation Cost & Time: One trench, one cable pull, one setup process.

- Space Savings: Crucial in crowded conduits, cable trays, or equipment cabinets.

- Higher System Reliability: Fewer independent components mean fewer potential failure points.

- Neater and Safer Installations: A single, organized cable run simplifies management and security.

Future Trends and Conclusion

The future for these cables points toward smarter, more functional infrastructure. Research includes technologies like Power over Fiber (PoF), which could transmit energy as light for complete EMI immunity. Integration with distributed sensing could allow the cable to monitor its own health. As the Internet of Things (IoT) and edge computing grow, demand for simple, robust solutions that deliver both power and high-bandwidth data will surge. The photoelectric hybrid cable is perfectly positioned as the foundational physical link for these next-generation networks, enabling smarter cities and more connected industries.

In summary, the photoelectric hybrid cable is a transformative solution that elegantly solves the dual challenge of power and data delivery. By integrating electrical conductors and optical fibers within a single, robust sheath, it streamlines deployment, enhances reliability, and reduces costs across telecommunications, industrial, and security applications. Its design inherently mitigates interference and withstands harsh environments. As technology advances toward smarter infrastructure and pervasive IoT connectivity, this cable will play an even more critical role as the backbone for efficient and future-proof installations.

FAQs

1. What are typical voltage and power ratings for hybrid cables?

Termination involves both elements. Typically, the cable ends in a junction box. The outer sheath is stripped. The optical fibers are spliced or fitted with connectors (like LC/SC) into a patch panel. The copper conductors are connected to terminal blocks or power connectors. Proper strain relief and sealing at the entry point are crucial, especially for outdoor use.

2. How do you terminate and connect a hybrid cable?

Termination involves both elements. Typically, the cable ends in a junction box. The outer sheath is stripped. The cs are spliced or fitted with connectors (like LC/SC) into a patch panel. The copper conductors are connected to terminal blocks or power connectors. Proper strain relief and sealing at the entry point are crucial, especially for outdoor use.

3. Can this cable be used for Power over Ethernet (PoE) applications?

Standard PoE uses Ethernet cable for both data and power but is limited to 100 meters. Photoelectric hybrid cables serve a different need. They are used when distances exceed PoE limits or when you need fiber’s high bandwidth and EMI immunity alongside remote power. They can deliver power over kilometers while the fiber provides gigabit+ data, making them complementary for longer-range, higher-performance applications.

4. What fire safety standards apply to these cables?

When installed indoors, they must meet relevant fire safety standards like any other cable. This includes UL listings (e.g., CM, CMR) in the US, CE CPR classifications in Europe, and LSZH requirements. The entire cable’s construction—materials for insulation, sheath, and fillers—is engineered to comply with these standards as a complete, integrated product.

Company Introduction: With over 20 years of deep industry expertise, we specialize in customizing and supplying solutions for optical fibers, cables, raw materials, and manufacturing equipment. We deliver reliable technical support and product services.

About the Author: With 20 years of hands-on experience in optical transmission media, cable assemblies, and core substrate materials, we offer practical, expert insights grounded in full-industry-chain expertise.