Shanghai Gengyun Industrial Co., Ltd

What is FRP Armored ADSS Cable? A Guide for Aerial Power & Telecom Networks

The Aerial Lifeline for Modern Grids

Modern power utility networks and Optical Distribution Networks (ODN) often need to cover large distances. Builders frequently use existing aerial infrastructure for this purpose. The FRP Armored ADSS Cable meets this specific need perfectly. This specialized optical cable works well in challenging aerial environments. Its key innovation is the complete removal of metallic parts. Instead, it uses a Fiber Reinforced Plastic (FRP) central strength member and aramid yarn. This creates a fully all-dielectric structure. The design allows safe installation near high-voltage power lines. It also provides a strong, long-lasting solution for communication backbones across varied landscapes.

- The Problem with Metal in Aerial Environments

Traditional aerial cables employed steel wires for strength. However, metal near high-voltage lines creates serious risks. Electromagnetic induction can produce dangerous voltages. Lightning strikes may cause severe damage. Long-term corrosion also reduces reliability. Additionally, metal’s weight puts extra load on support structures. These issues required a new approach. The industry needed a non-metallic, self-supporting aerial cable. This cable would handle mechanical stress without creating electrical dangers.

- The ADSS Solution: Strength Without Conductivity

The All-Dielectric Self-Supporting (ADSS) concept addresses this need. “All-Dielectric” means every part acts as an electrical insulator. “Self-Supporting” indicates the cable has built-in tensile strength. It can span distances between poles without needing a separate messenger wire. The FRP Armored ADSS Cable realizes this concept through advanced material science. It uses modern composites to provide mechanical integrity. These materials replace traditional metals but avoid all related electrical risks.

Technical Design and Core Performance Advantages

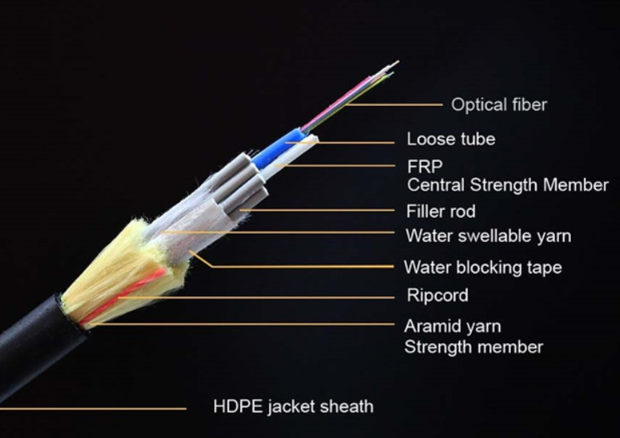

The FRP Armored ADSS cable excels because of its layered construction. Each layer contributes specific performance attributes.

- Layered Construction: A Symphony of Materials

A typical cable builds from the inside out:

- Optical Unit: At the core, optical fibers (like G.652.D) sit in a loose tube or central tube structure. Manufacturers often fill this with water-blocking compound for moisture protection.

- Primary Strength Layer: The first mechanical defense is braided or longitudinal aramid yarn (e.g., Kevlar®). This material offers an excellent strength-to-weight ratio and high impact resistance.

- Central Strength Member: The cable’s backbone is the FRP rod. This pultruded composite consists of glass fibers in a resin matrix. It provides the main tensile strength (often > 500 MPa). It also resists long-term creep and sag under continuous load.

- Buffer/Inner Sheath: A protective inner layer may surround the assembly.

- Outer Sheath: The final layer is a specially formulated sheath. It resists electrical tracking and environmental weathering. The material is UV-stabilized polyethylene.

- Key Performance Advantages in Detail

- Electromagnetic Safety: The all-dielectric design completely avoids induced voltage and short-circuit currents. It eliminates the need for grounding. This makes installation simpler and inherently safer near power lines.

- High Mechanical Strength and Durability: The FRP and aramid yarn combination withstands extreme tensile loads. These come from ice, wind, and the cable’s own weight over long spans. It also resists vibration fatigue well.

- Environmental Resistance: The outer sheath provides superior defense. It protects against UV radiation, ozone, and wide temperature changes. Its tracking resistance is crucial near industrial areas or coastlines with polluted air.

- Installation Flexibility: The cable is relatively lightweight. It also has a small minimum bending radius. These features make handling, splicing, and installation easier. Workers can install it on existing towers without heavy equipment.

Applications and Strategic Deployment Value

The FRP Armored ADSS cable finds strategic use where safety, reliability, and infrastructure leverage are top priorities.

- Primary Application Scenarios

- Smart Grid & Power Utility Communications: This is the classic application. The cable supports distribution automation and substation interconnects. It enables fault detection and SCADA systems. It reliably runs on the utility’s own pole lines.

- FTTH/ODN Long-Haul Backbone: Builders deploy it to cross fields, rivers, and highways. It provides a strong backbone link between central offices and remote points in Fiber-to-the-Home networks.

- Wireless Backhaul for 4G/5G: It serves as a high-capacity fiber link to remote cell towers. Often, it shares right-of-way with power lines.

- Industrial & Private Network Crossings: It is ideal for secure, interference-free links. These connect large campuses, mines, or railways where crossing power lines is unavoidable.

- Deployment Advantages Over Traditional Cables

Compared to Optical Ground Wire (OPGW) or metal-clad aerial cables, the FRP Armored ADSS cable offers clear benefits:

- Lower Lifetime Cost: It requires no grounding. Its lighter weight makes installation cheaper and easier. It also needs less maintenance.

- Faster Deployment: Workers can install it on live power line structures. This avoids major downtime and safety hazards near energized conductors.

- Superior Safety Profile: It eliminates risks of electrocution or induction for installers and utility staff.

- Infrastructure Optimization: It maximizes use of existing power corridor rights-of-way. This avoids the cost and delay of securing new paths.

Future Trends and Conclusion

As power grids become smarter and telecom networks expand, reliable aerial fiber will grow in importance.

Future developments will focus on cables with higher fiber counts. They will support bandwidth growth while keeping good mechanical properties. Sheath materials will gain enhanced hydrophobicity and pollution resistance for harsher climates. Also, integration of distributed fiber sensing within the ADSS cable is an emerging trend. This allows the cable to monitor temperature, strain, or vibration along the entire power line. It turns the communication link into a smart grid sensor for predictive maintenance.

In conclusion, the FRP Armored ADSS Cable is a masterfully engineered solution. It redefines safety and reliability for aerial fiber optic deployment. By replacing metal with advanced composites, it solves problems of electromagnetic interference and corrosion. It also delivers the mechanical strength needed for demanding overhead installations. Its use in smart grid communications and ODN backbones is a strategic choice. It enables utilities and telecom operators to build resilient, future-proof networks efficiently and safely. As demand for robust, intelligent infrastructure grows, this all-dielectric cable will remain indispensable for connecting the modern world.

FAQs

1. What is the typical span length for an FRP Armored ADSS cable?

The maximum span length depends on the specific cable design, local weather conditions, and required sag clearance. Typical spans range from 80 to 150 meters. However, engineering calculations based on local conditions and safety factors are essential for every project.

2. How is the installation tension calculated and controlled?

Installation is critical. The cable manufacturer specifies the Maximum Allowable Tension (MAT) and Everyday Stress (EDS) based on mechanical properties. Installers use tensioners and dynamometers to control pulling tension strictly. This ensures tension never exceeds the MAT. Proper tensioning guarantees correct sag and prevents over-stressing.

3. Can this cable be installed on the same pole as medium-voltage or high-voltage power lines?

Yes, this is a primary application. However, national electrical safety codes strictly govern installation height and separation distance from power conductors. The cable must be placed at a specified, safe distance below the power lines. Its all-dielectric nature makes this proximity safe, unlike with metallic cables.

4. What does “track resistance” mean for the sheath, and why is it important?

Electrical tracking occurs when surface contamination creates a conductive path on the sheath. This can lead to gradual erosion under the electric field from nearby power lines. A track-resistant sheath uses special additives to inhibit this process. This is vital for long-term weathering performance and dielectric integrity, especially in polluted or coastal areas.

Company Introduction: With over 20 years of deep industry expertise, we specialize in customizing and supplying solutions for optical fibers, cables, raw materials, and manufacturing equipment. We deliver reliable technical support and product services.

About the Author: With 20 years of hands-on experience in optical transmission media, cable assemblies, and core substrate materials, we offer practical, expert insights grounded in full-industry-chain expertise.